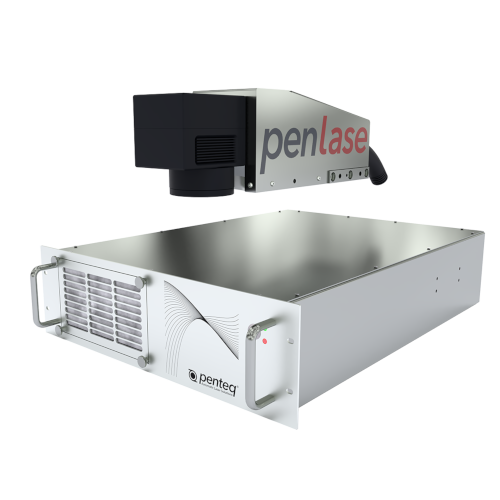

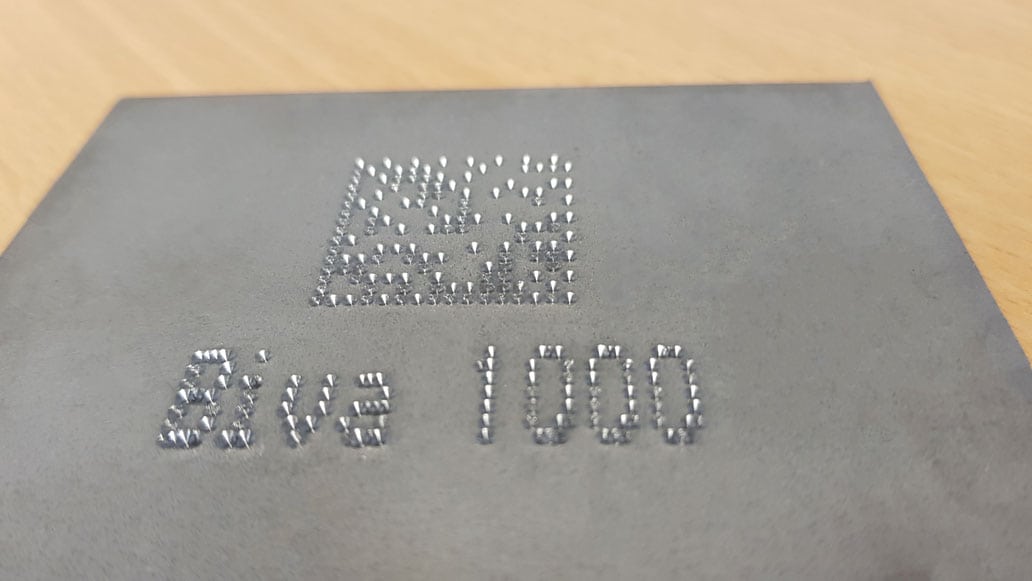

NEEDLE EMBOSSING SYSTEM

FOR DATAMATRIXCODES ECC200

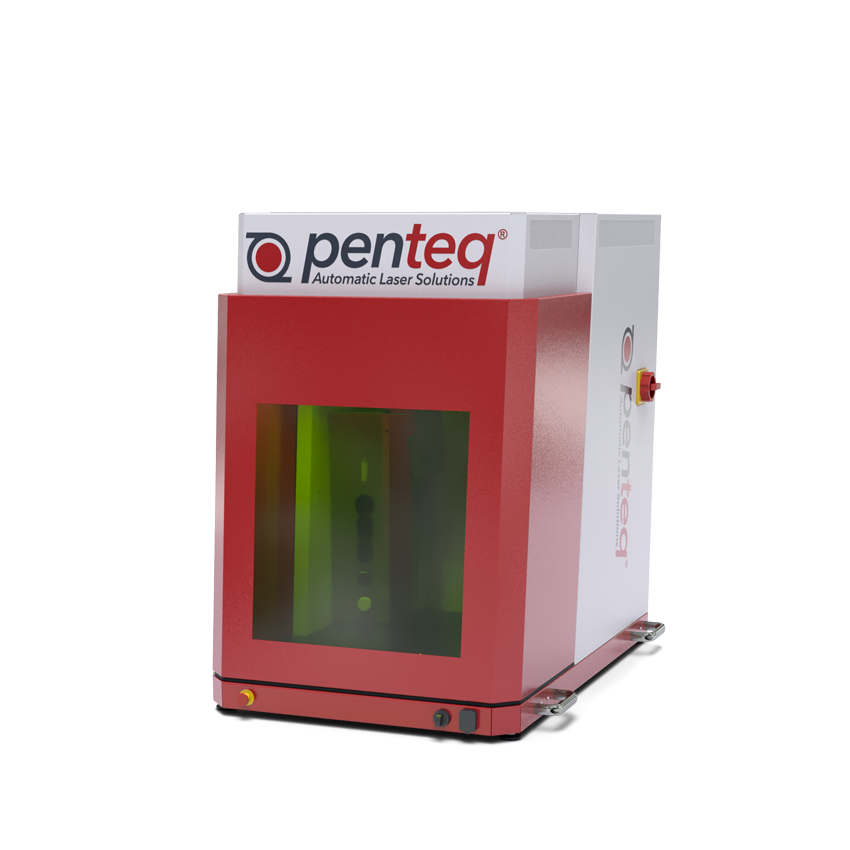

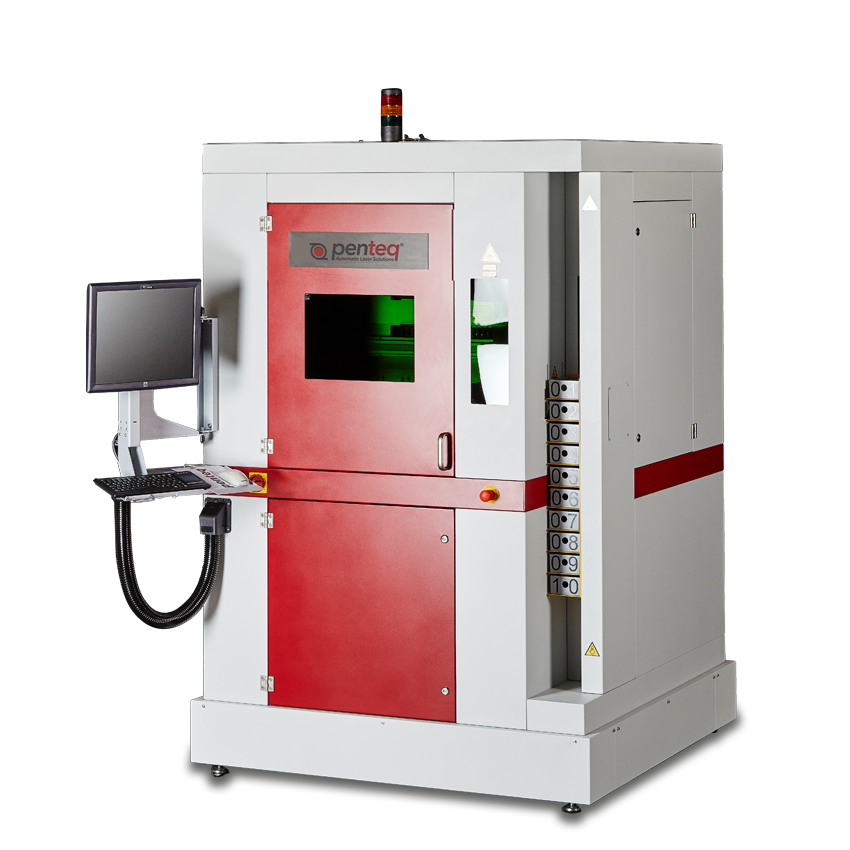

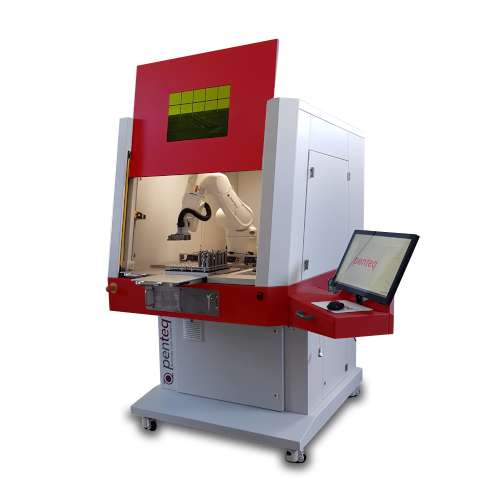

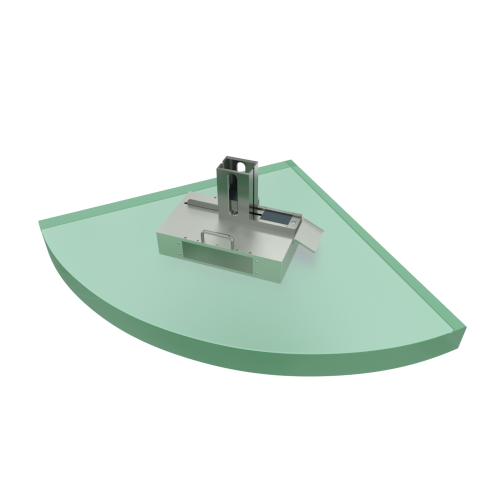

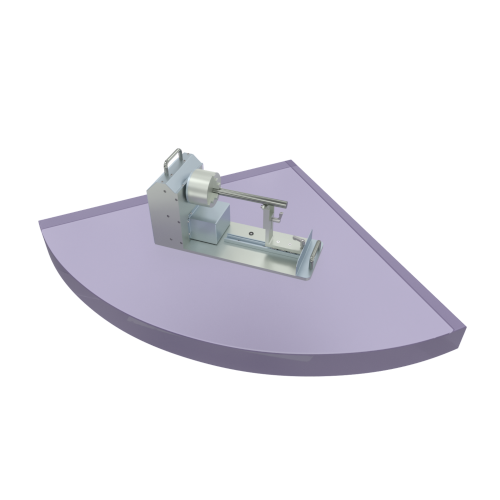

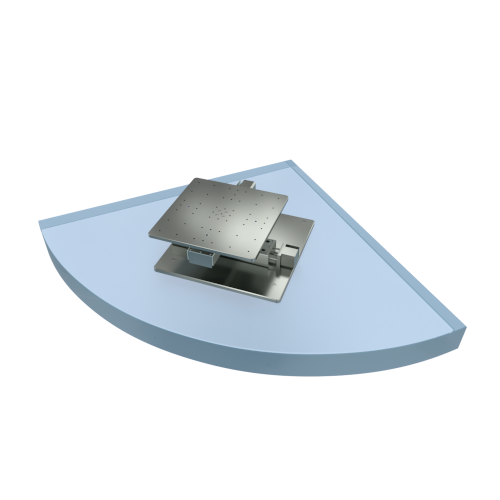

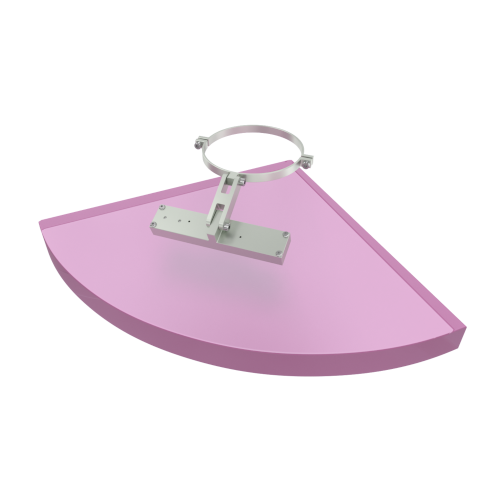

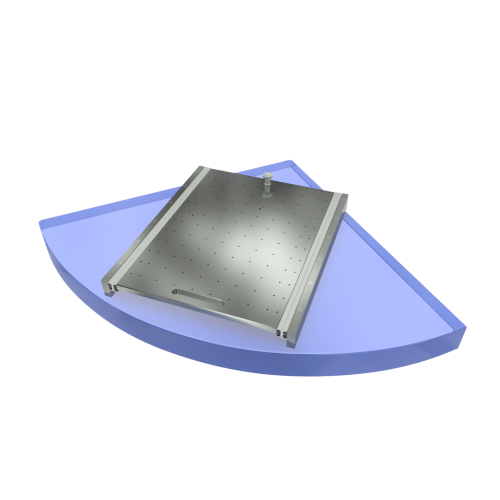

Automatic needle stamping machine with integrated code check for easy integration

Massive design in steel welded construction for harsh use in industrial environments

Features of the DMC needle embossing System

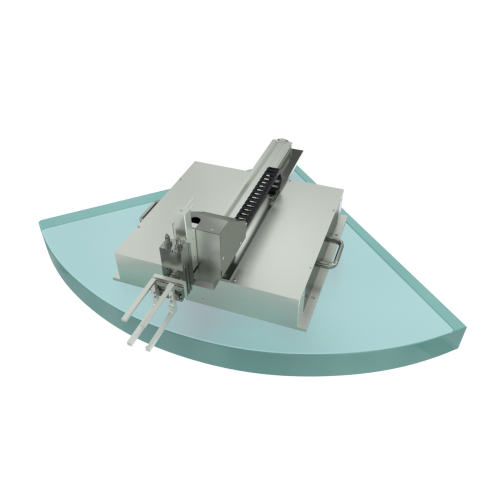

- Complete solution for DMC markings for Product tracing

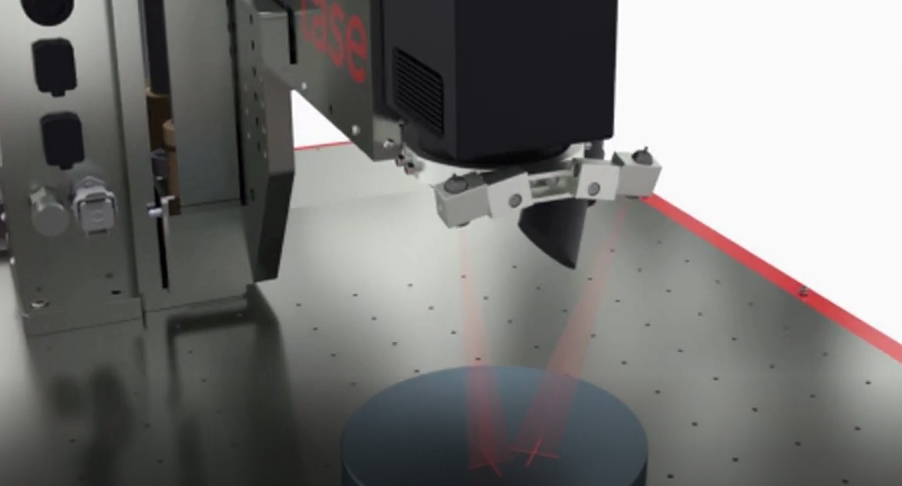

- Fast and precise direct markings on metallic materials

- Penetration depths up to 0.5 mm depending on material properties

- Marking data matrix codes and plain text

- Automatic position compensation for the material surface

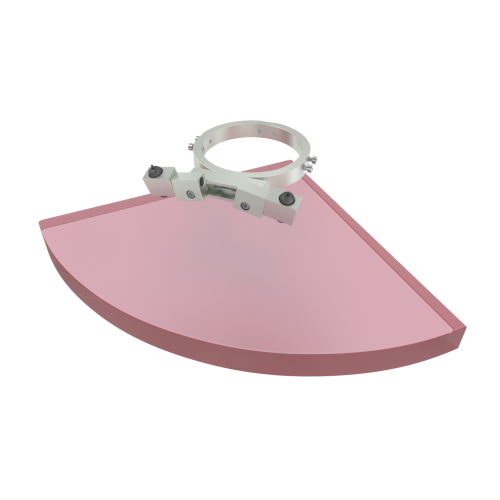

- Subsequent verification of the codes by counter-reading

The large penetration depth of the pneumatically operated embossing needle ensures long-lasting and flawless readability, even after further processing after embossing such as thermal treatments or varnishing with a low layer thickness.

The needle stamping machine has an automatic delivery to the marking surface. After the marking position is reached, the embossing process takes place.

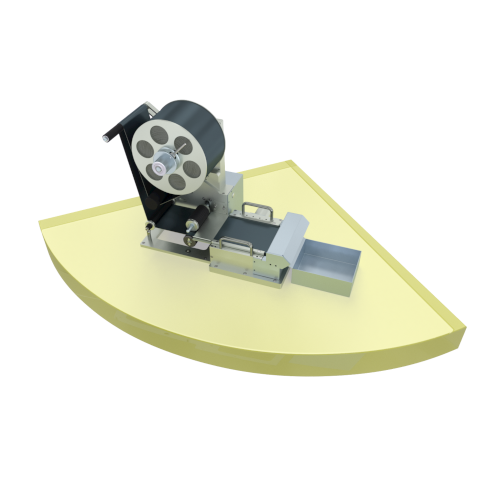

After the needle embossing, the integrated vision will read the embossing.

The contents of the read-out code are compared with the transferred data of the embossed content. If readability is not given, the system outputs a Fehlermeldlung.

The system is ideally suited for line integration and can be connected to ERP systems or databases via standard interfaces.

Advantages over lasers are:

- Lower acquisition costs

- Large penetration into the material in a relatively short time

- The material compaction enables detection even after material removal up to the embossing depth.

Penteq needle stamping machine have been specially developed for industrial applications.

We support our customers with the introduction of a complete traceability system including software solutions!