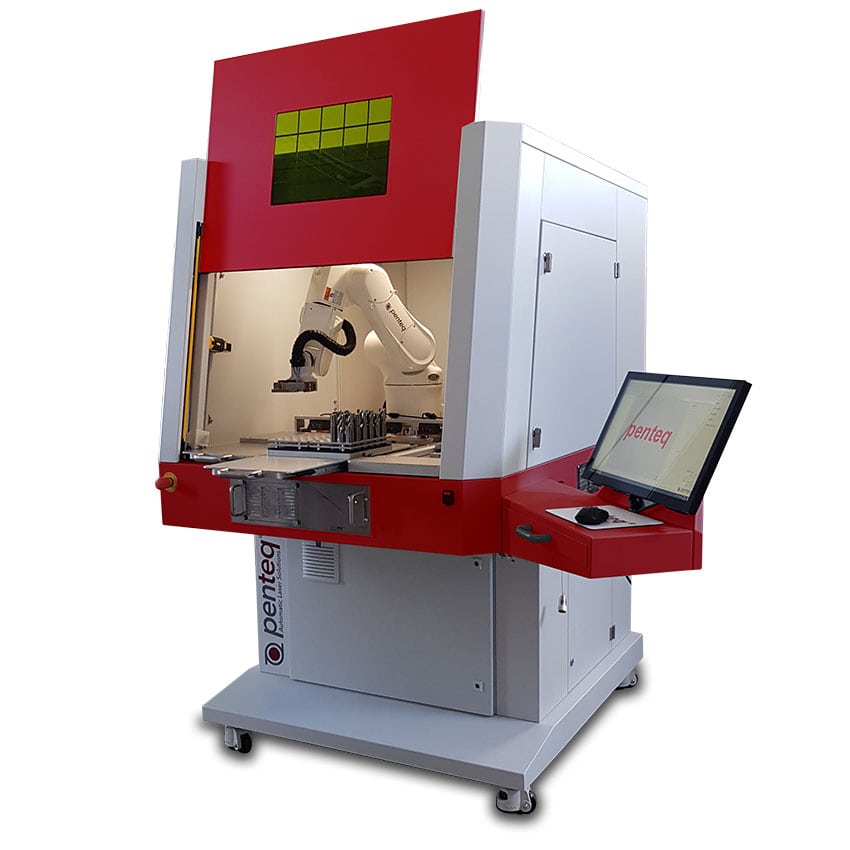

Laser workstation LG 300 Robo

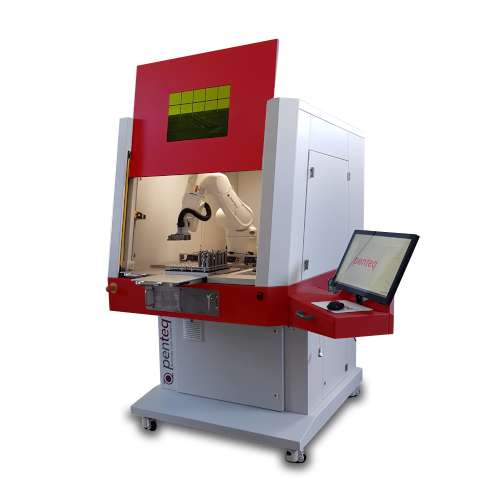

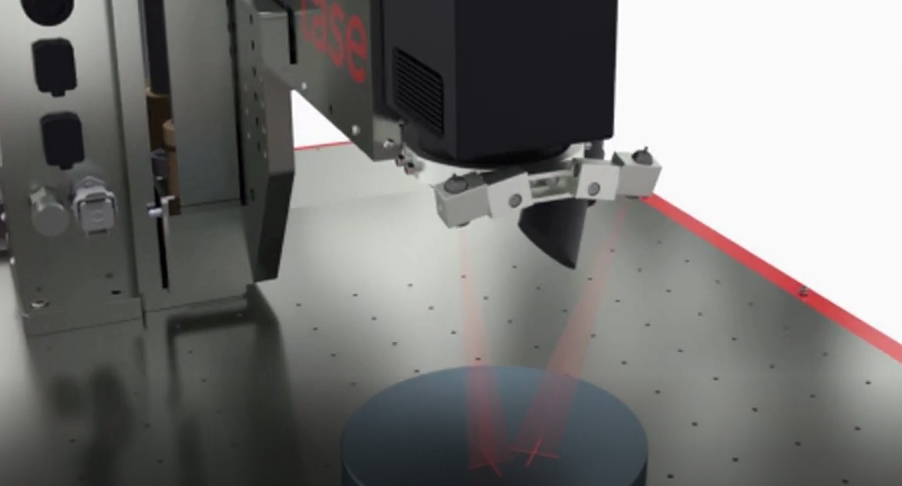

The LG 300 Robo Laser Workstation is the optimal solution for the automatic marking of tools or a large number of small, palletizable workpieces.

The fully integrated robot enables unprecedented productivity and positions the workpieces with the desired marking surface under the laser. For example, in the case of cutting tools, a label on the Shank facade or on the Shank Size Side Feasible.

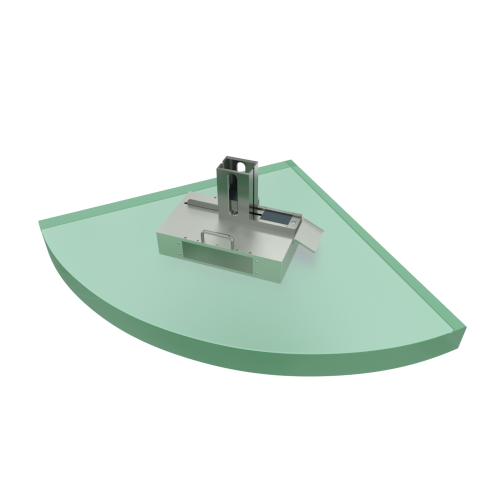

With the optional function module Double extension table kann die Produktivität weiter erhöht werden. Der Bestückungs- und Entnahmevorgang kann zur Erzielung einer Produktion ohne Stillstandszeiten während der Laserbearbeitung erfolgen.

Basic system characteristics

- Control via integrated industrial PC

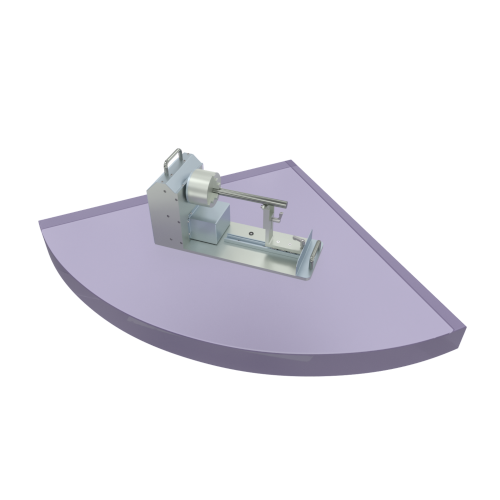

- Fully integrated 6-axis industrial robot

- All necessary components such as laser cabin, control, supply unit and suction in one system.

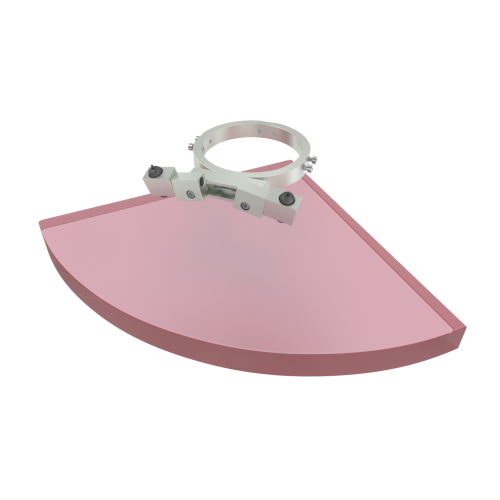

- Cutter diameter from 3 to 20mm

- Automatische Palettenerkennung

- Dimensions: 1200 x 1510 x 2200 mm

- Generous door for optimal approach to the working area

LG 300 Robo Laser workstation

The Penteq Laser Workstation LG300 Robo is the complete solution for tool manufacturers.

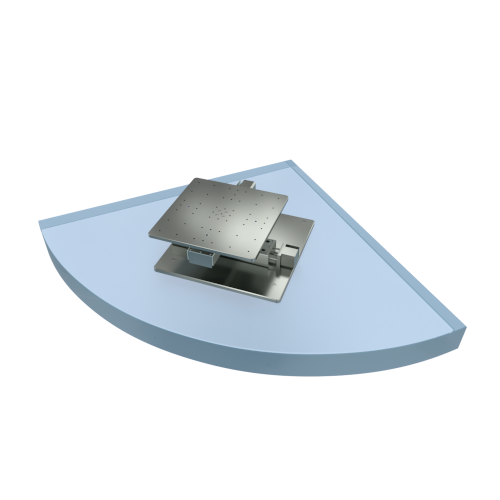

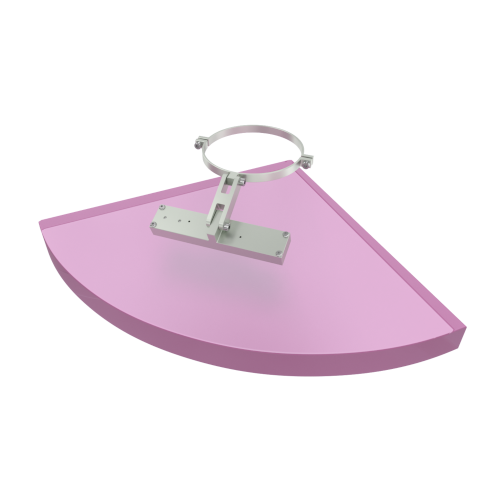

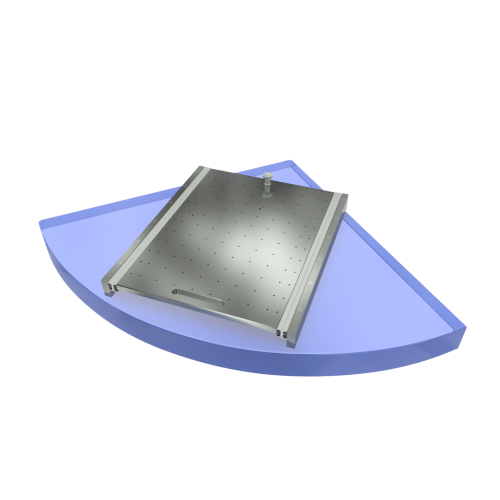

The concept of the double extract table offers various advantages over rotary table systems:

- Larger reception area for high load capacity

- separate Position für Sonderwerkzeuge

- Alternative edits by dividing right/left station.

- Automated flow through control technology integration of the double table

High productivity

In addition, the double Extract table module offers the possibility to carry out the assembly and removal of one table simultaneously to the marking process.

This enables high throughput to be achieved for processing large quantities.

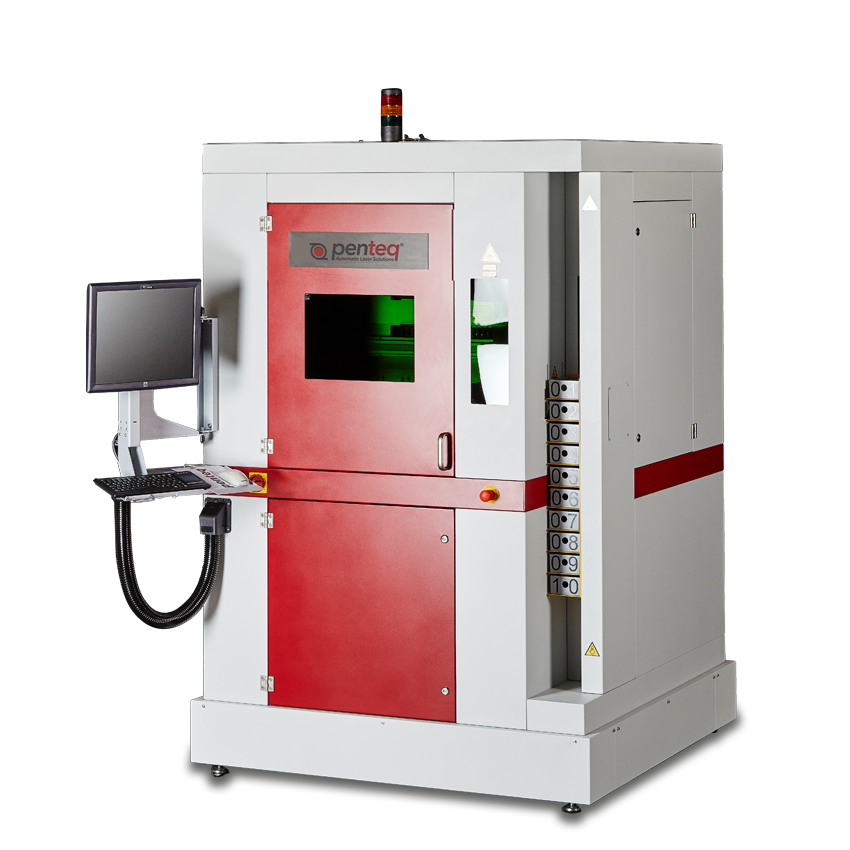

The sturdy and powder-coated steel construction of the protective cabin is designed for long-term industrial use.

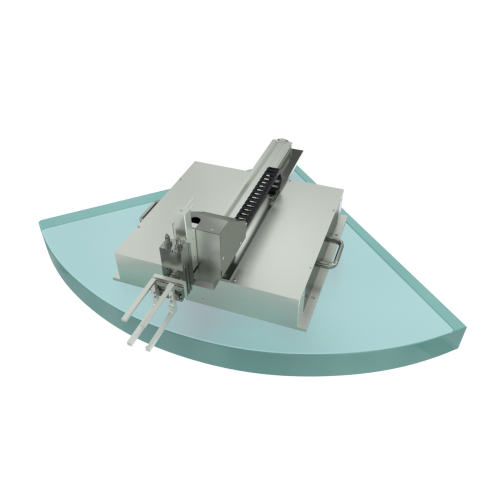

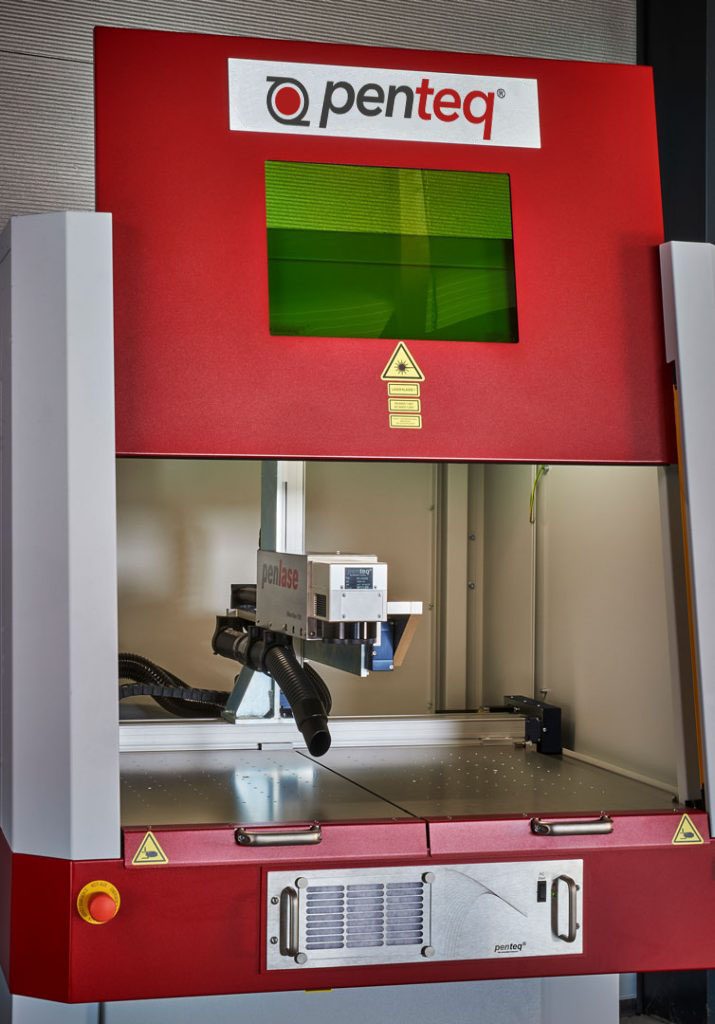

Big tumble

The upward sliding tumble is large in size to allow optimum access to the working space.

To reduce off-peak times, the door's stroke can be limited by the control to eliminate unnecessary Leerwege.

A generous, CE-certified Laser Protection window provides insight into visual process observation.

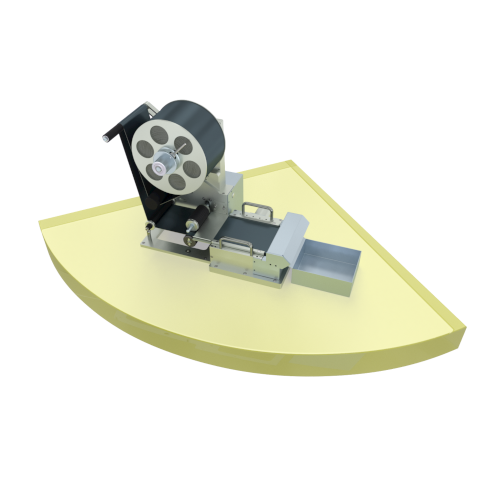

LG300 Robo for milling tools

Perfect for large quantities of hard metal tools. Due to the specially configured beam source, high-quality marking results can be achieved.

A label with data matrix codes can be the basis for a complete tracing system.

Through the software-side interfaces, a simple integration into the internal data landscape is feasible.

Consistent product tracing

In interaction with the PENAPP track ' n Trace a consistent system for product tracing can be installed, which takes into account the customer-specific requirements.

Complete Package

Included is the PENTEQ software package with graphics editor.

The texts to be labelled can be entered easily and graphics can be compiled or drawn with a mouse click.

Furthermore, an import function for logos or graphics from various formats such as:. dwg;. dxf;. HPGL;. svg and Bitmap is available

| Dimensions of working space: (WxDxH) | 1000 x 500 x 300 mm |

| Dimensions: (WxDxH) | 1200 x 1510 x 2200 mm |

| Capacity Milling tools: | From 3 to 20 mm diameter |

| Maximum weight of the workpiece: | 1000 g |

| Laser Smoke Extraction: | Integrated |

| Weight of the system: | 650 kg |

| Laser class: | 1 |

| Observation camera | ||

| DMC Camera | ||

| Pilot Laser | ||

| Focus Finder | ||

| Foot | ||

| Monitor on swivel arm | ||

| Handheld scanner for codes | ||

| Touchsreen | ||

| Bad Partsbox | ||

| 3-Stage State light |