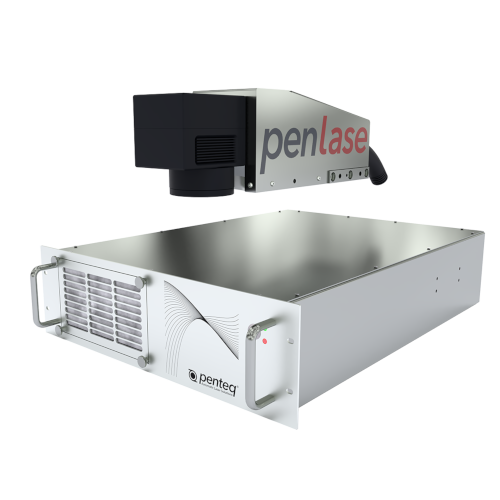

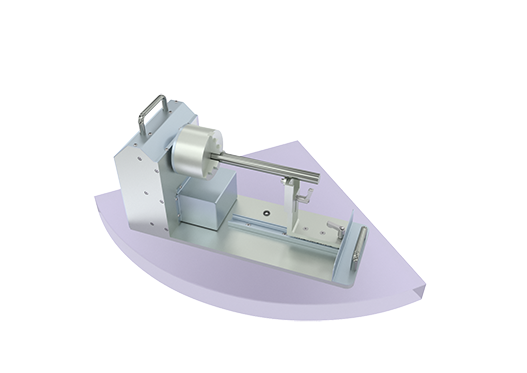

function modules

Penteq function modules - enable anytime and interchangeable additional functions.

In the following we offer an overview of some standardised function modules for the extension of various basic machines.

The range of FunctionModules is constantly being expanded and extended. New function modules are being added all the time.

In addition, also Custom Function modules developed.

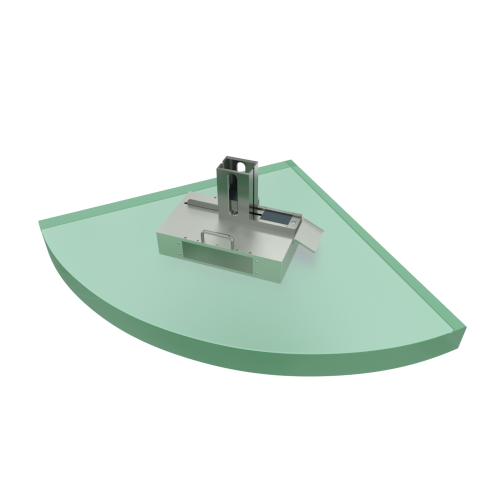

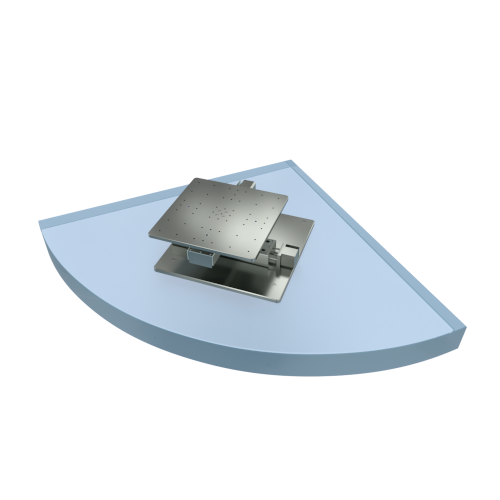

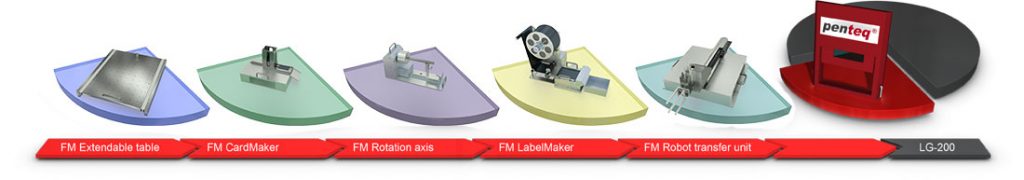

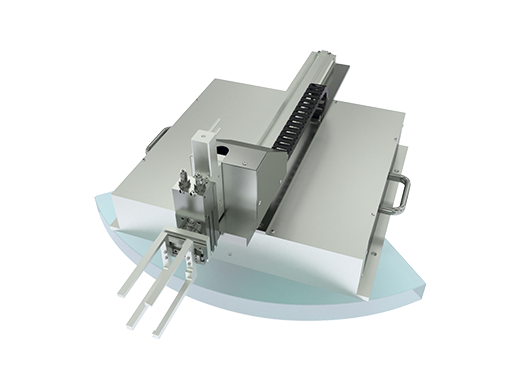

FM Pull-Out table

For setting and furnishing, as well as for the reception of large or heavy parts, the door can be opened completely and the operating table is removed in the direction of the operator.

Another advantage is the ability to easily mount special recording devices.

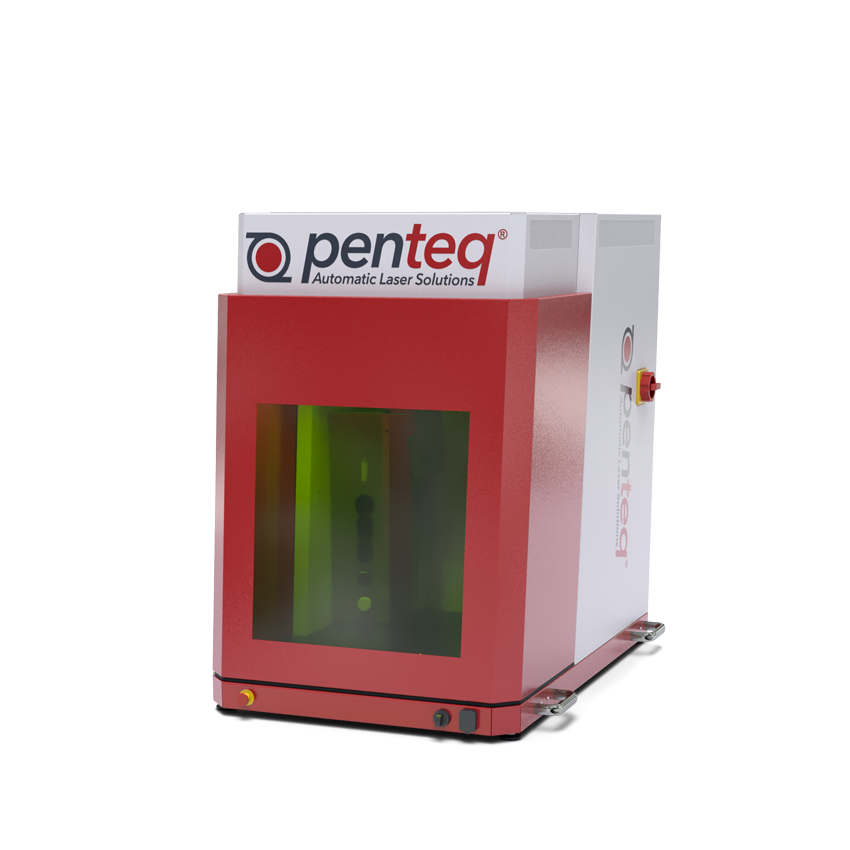

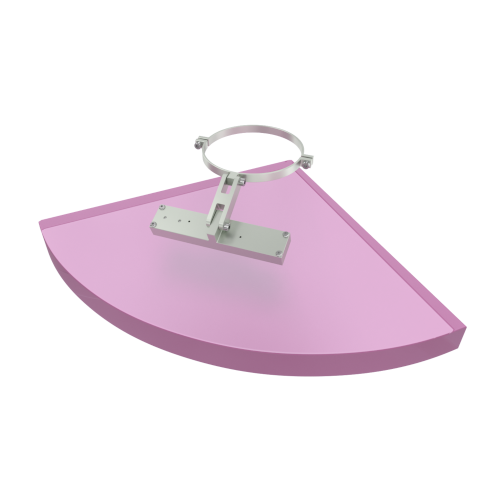

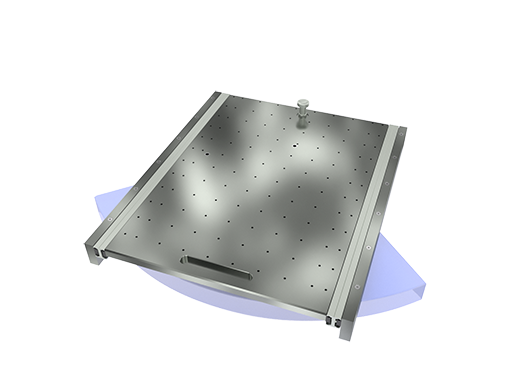

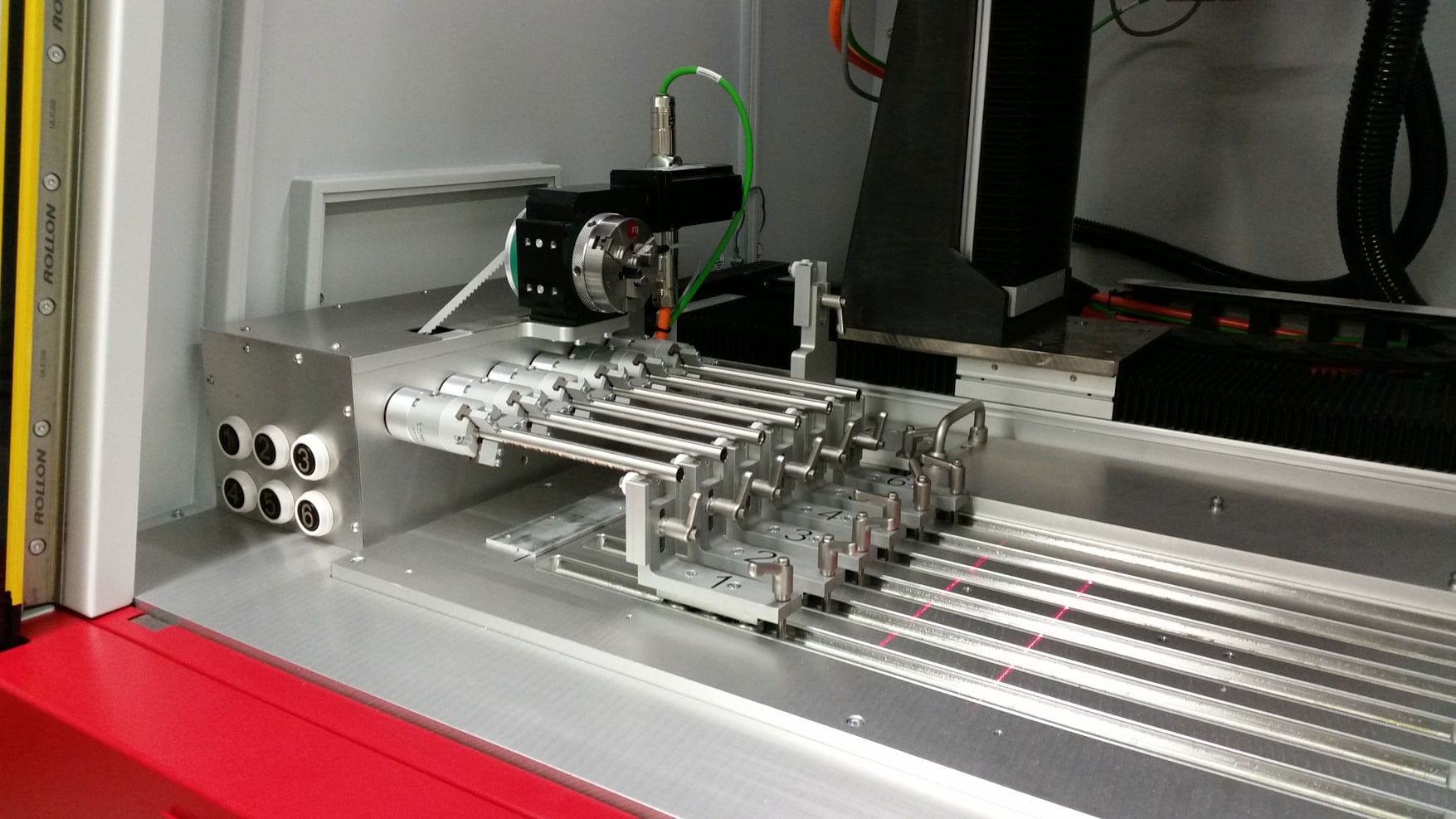

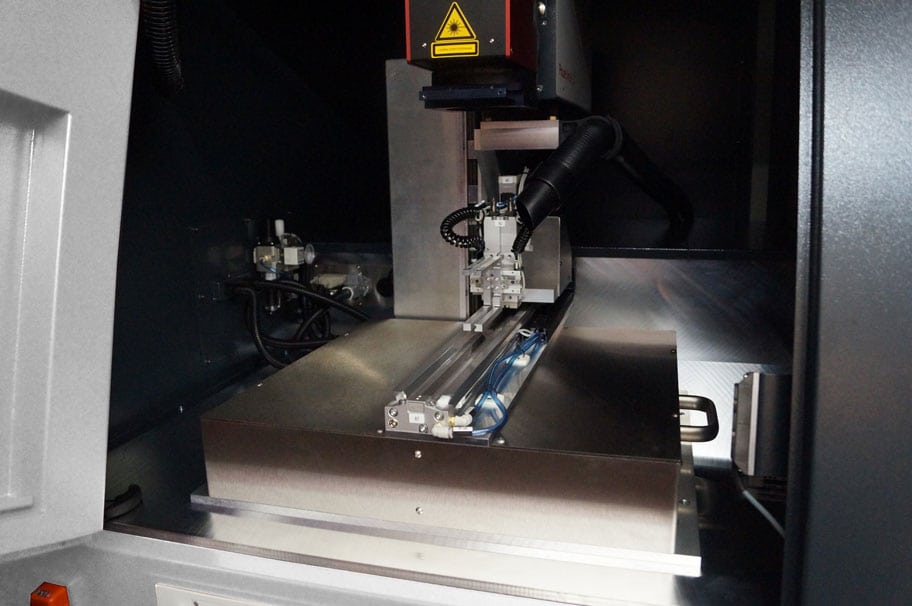

FM CARDMAKER

From the manual machine to the sign machine. With the function module Cardmaker, type plates can also be labeled automatically with serial number or variable data.

A magazine attachment for a shield size of your choice is included in the scope of delivery. The magazine attachments can be changed quickly and toolless and are also suitable for storing the blanks of the signs in the machine.

For plate sizes from 20 x 20 to 100 x 120mm. Filling magazine approx. 140mm

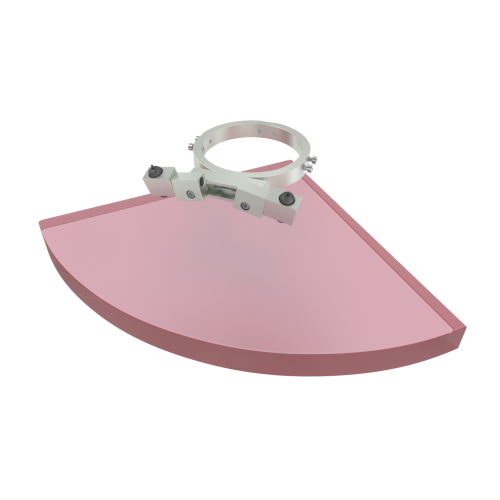

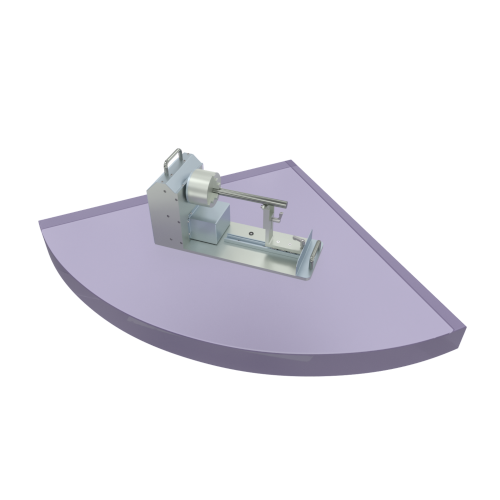

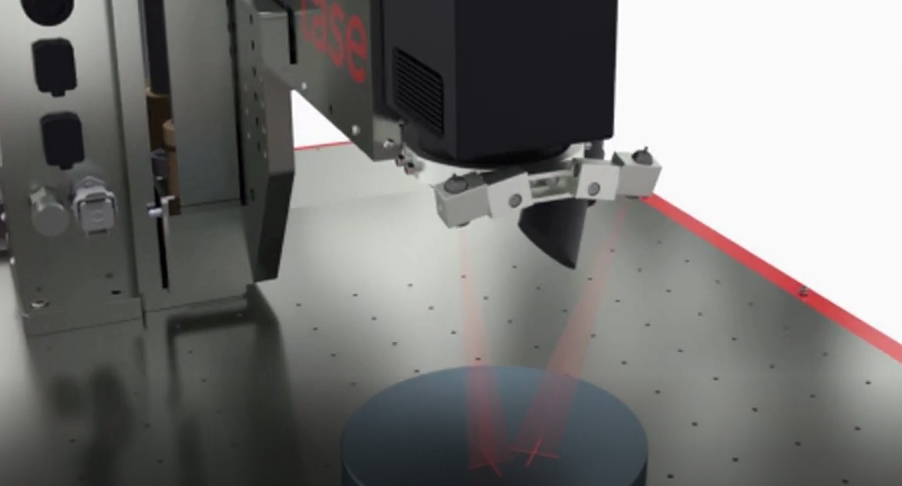

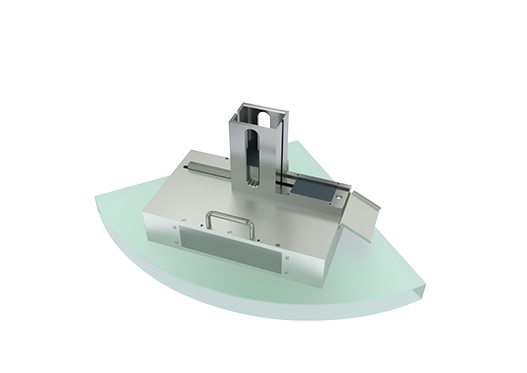

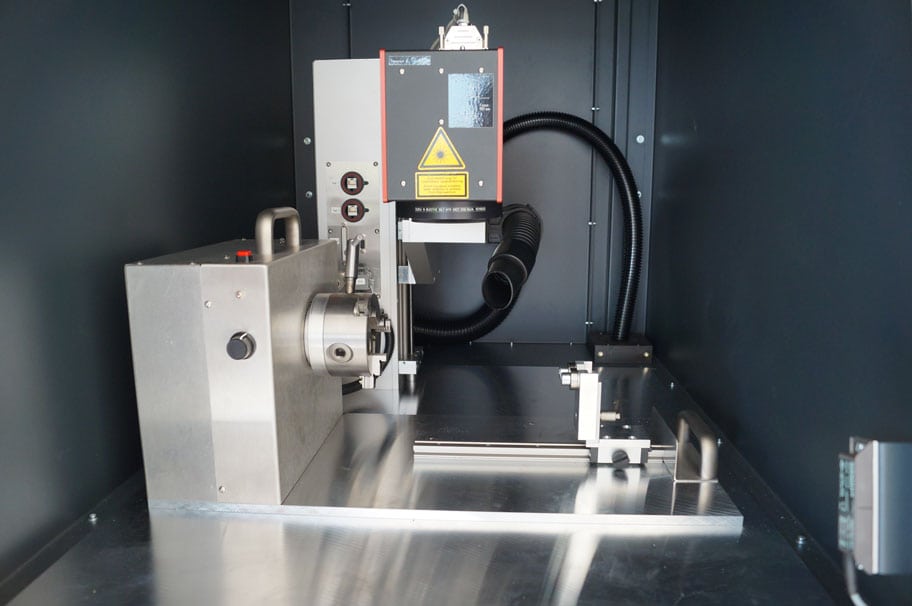

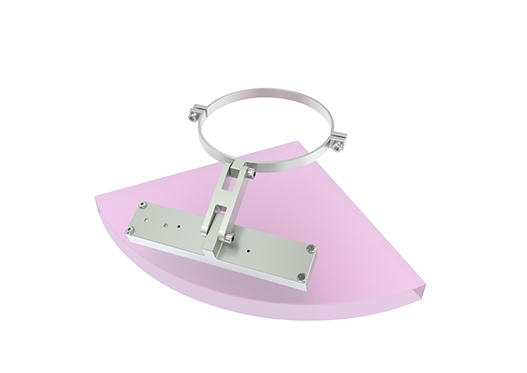

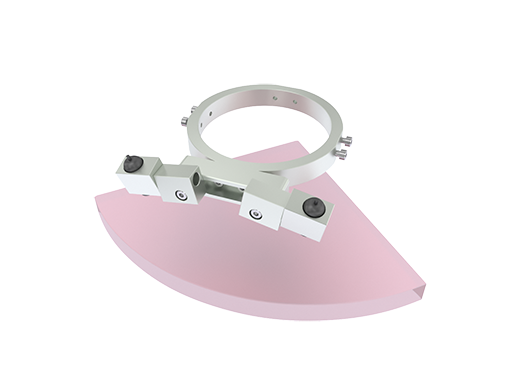

FM axis

The function module axis of rotation (partial apparatus) is used for the segmentation of the mantle surface on cylindrical components.

A manual 3-jaw chuck is included in the scope of delivery.

(Fig. 2 Special version Multi-axis)

This enables parallelism to the laser focus plane to achieve flawless labeling results.

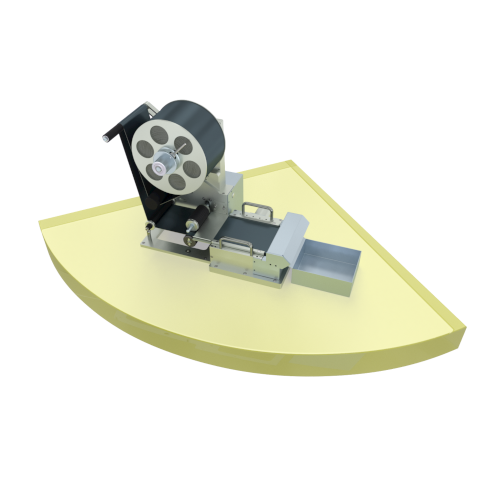

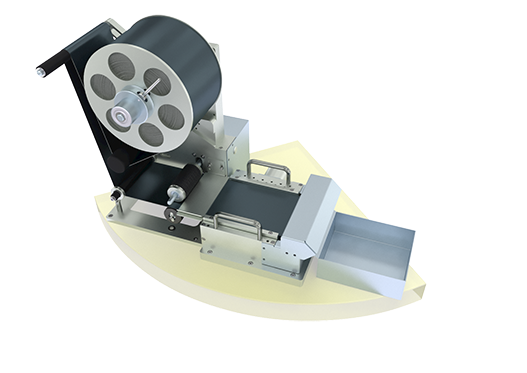

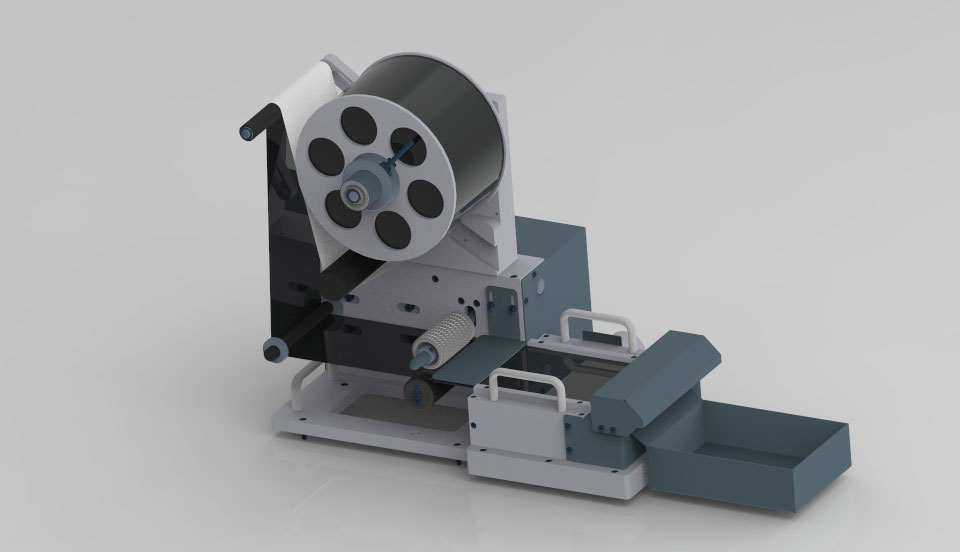

FM LABELMAKER

Represents an ideal solution for the identification of very large and heavy workpieces or for example machines.

Labeling and trimming the labels from the reel allows the production of any desired label size and shape up to 120 x 120mm using only one laser film.

The contents are labelled with clear text, codes (e.g. barcode or data matrix codes, QR codes) and logos as well as the cutting in one pass.

The laser labels meet all legal standards and can be used as forgery-proof identification solutions throughout the life cycle of a product.

They are particularly resistant and durable against chemicals, solvents, abrasion, extreme temperatures and weather conditions.

The laser labels are also suitable as data carriers for traceability (data matrix code) as well as intelligent process control and cannot be removed without destruction.

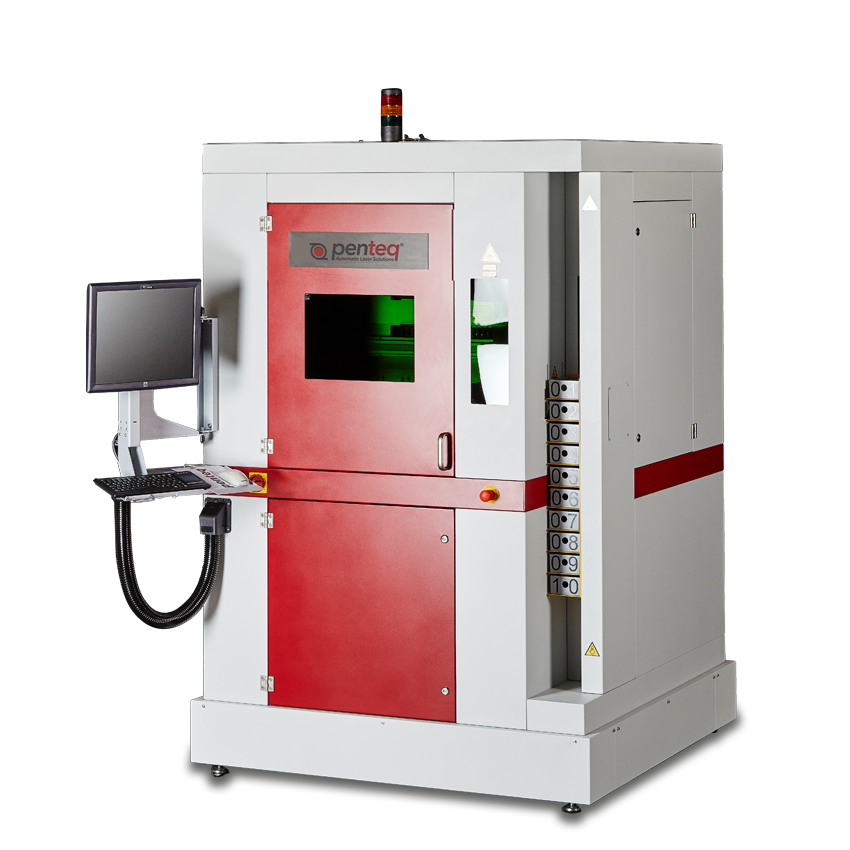

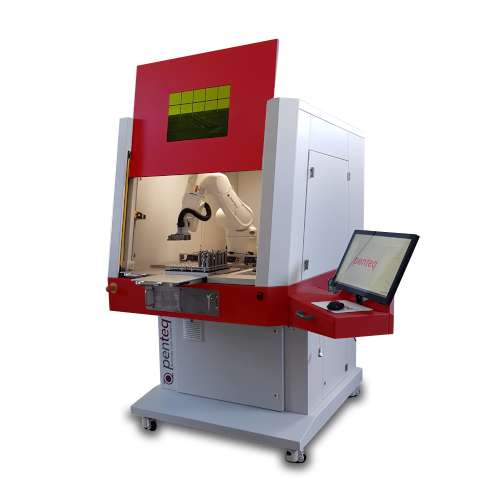

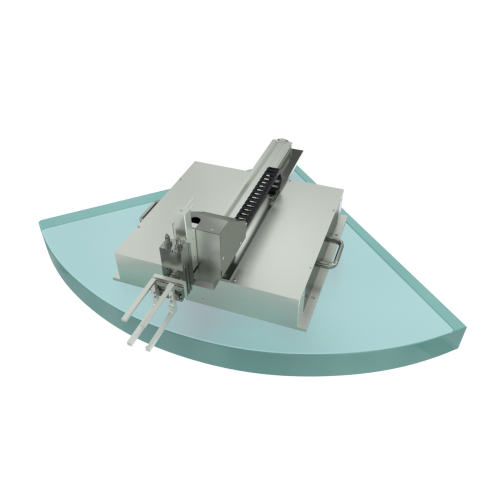

FM Robot Transfer Unit

For easy connection to a robot for the automatic transfer/transfer of the workpieces to be worked, including the required interfaces.

Consisting of an automatic, retractable workpiece carrier including base plate for assembly for customer-specific recordings of the parts to be annotated.

The label operation starts. Then the flap opens and the workpiece carrier moves out of the laser casing and provides the finished part for removal.

An optional turning device for multi-page marking can be used on the carrier.

The FM automatic is a prerequisite for the use of the FM robot transfer unit. The compressed air connection must be provided by the customer (6 bar).

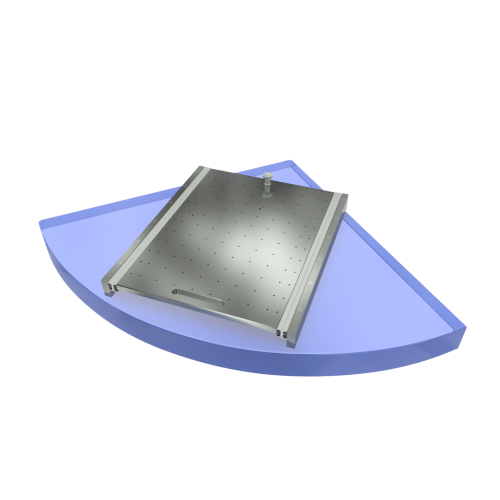

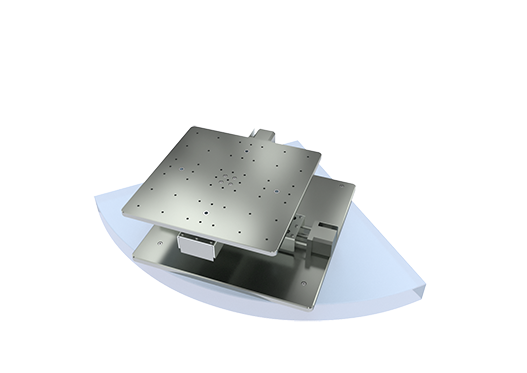

FM x/Y table

The automatically moving x/Y table allows you to enlarge the marking field in X and Y direction and provides higher productivity for different applications.

The labeling of several small parts can be automated in one loading and thus reduce the downtime by loading and unloading operations.

FM PENVISION SMART ADJUST

The workpiece becomes visible behind the transparent layout and the labelling can be placed directly at the desired position using the mouse pointer.

FM FOCUS FINDER

The focus finder provides a quick and easy way to precisely focus the laser beam without measuring the workpiece height, allowing the correct working distance to be set for the application.