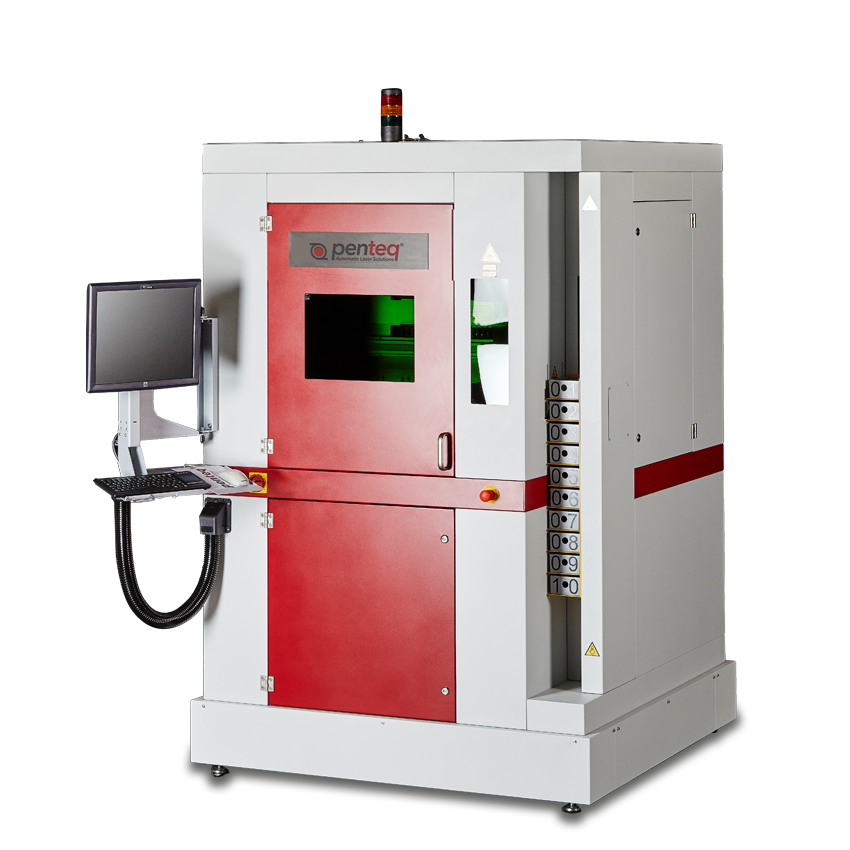

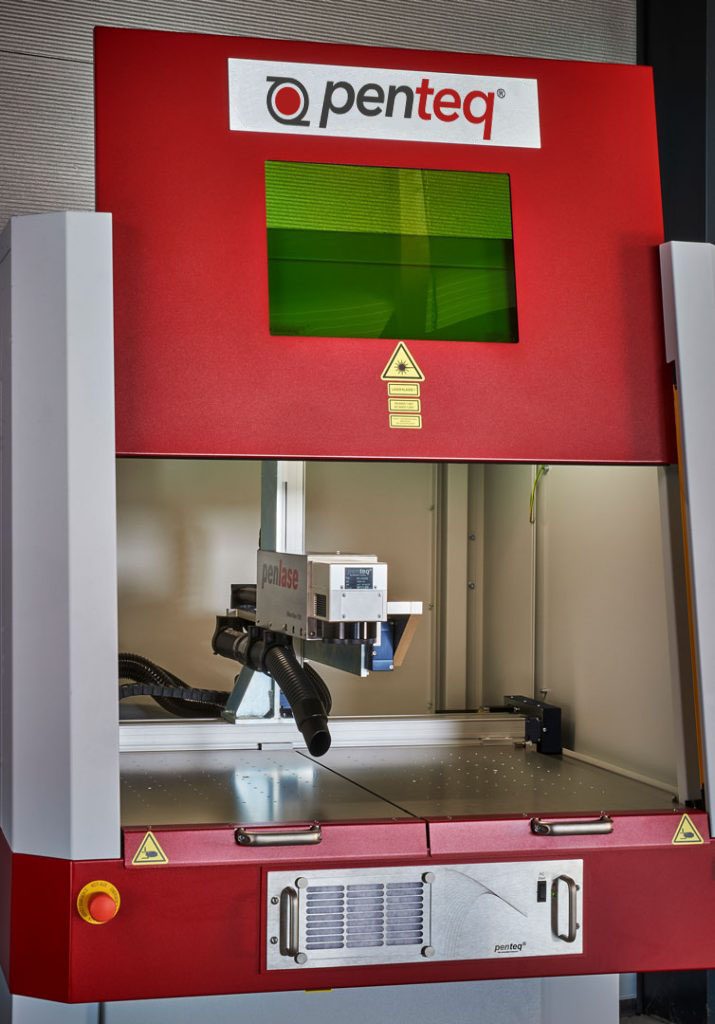

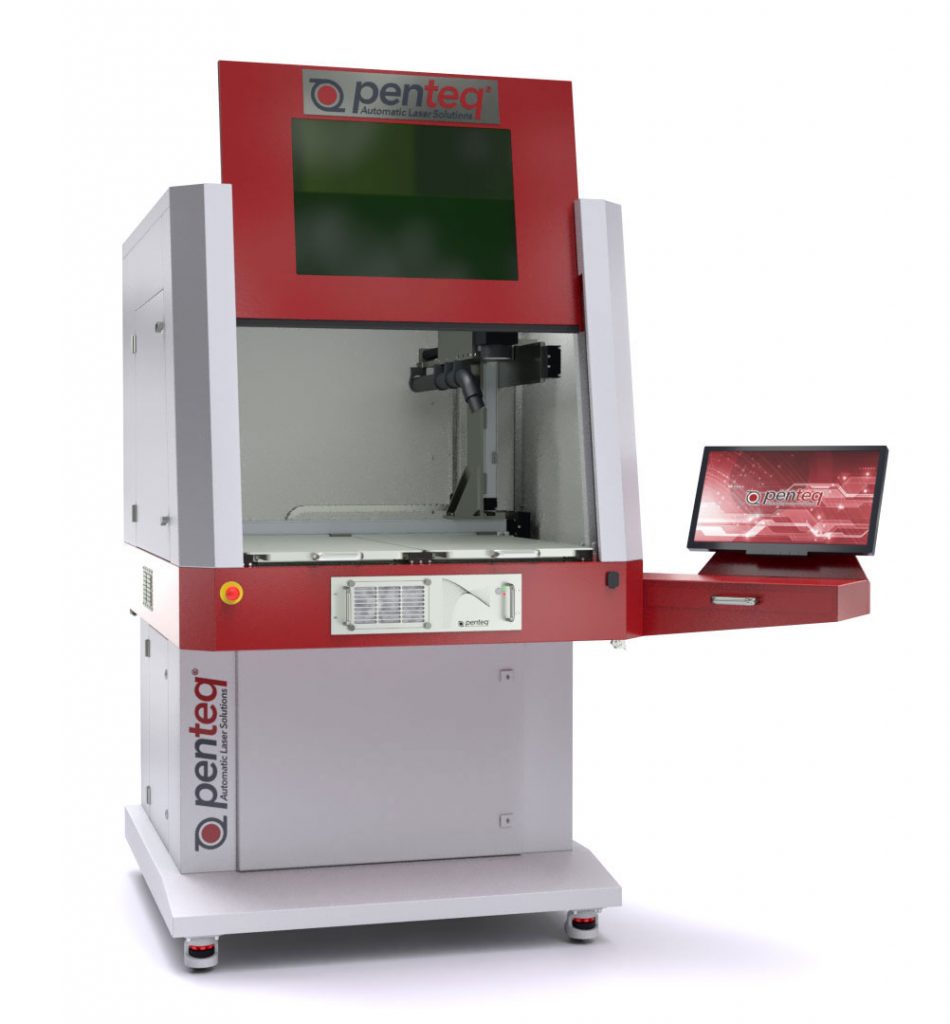

LG 300 Laser Workstation

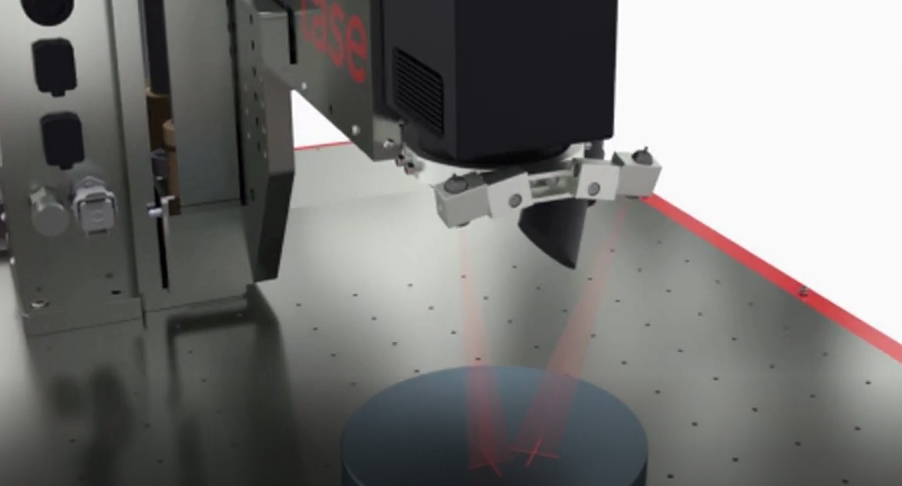

The LG 300 Laser Workstation is the solution for the marking of large workpieces or a large number of small workpieces.

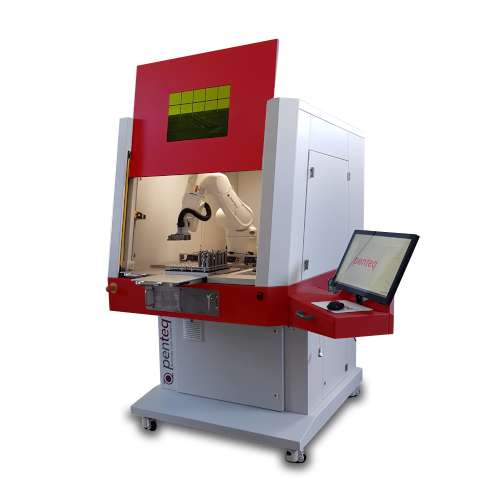

With the optional function module Double extension table the productivity can be greatly increased and thus represents an alternative to turntable laser devices.

Basic system characteristics

- Control via integrated industrial PC

- Can be equipped with up to 5 controlled axes

- All necessary components such as laser cabin, control, supply unit and suction in one system.

- Standard label field 150 x 150 mm (Other areas on request)

- Generous working space (1000 x 500 x 300mm)

- Dimensions: 1200 x 1510 x 2200 mm

- Generous door for optimum laser room

LG 300 Laser Workstation

The Penteq LaserWorkStation LG300 enables the marking of many workpieces with small dimensions in one load or large and heavy workpieces made of different materials due to its large working area.

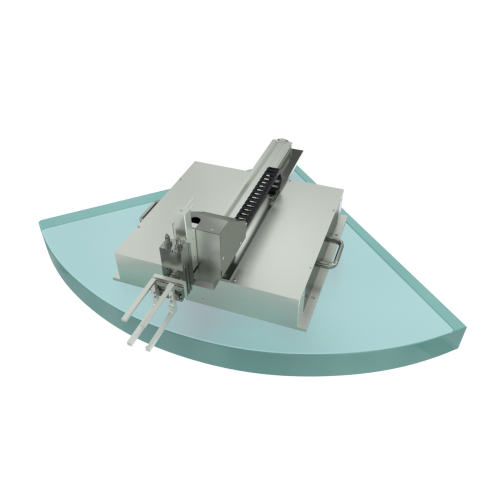

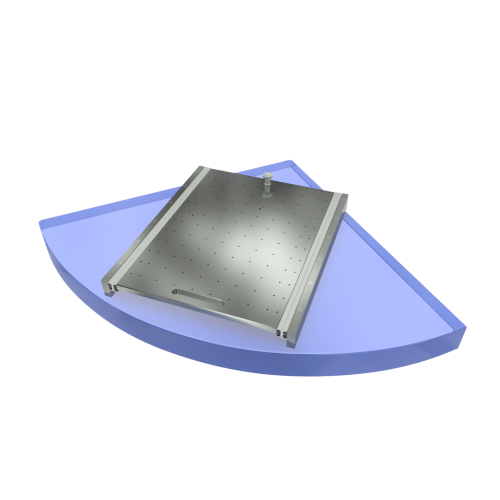

The concept of the double extract table offers various advantages over rotary table systems:

- Larger reception area for high load capacity

- Rectangular table tops compared to the "pie piece" in the turntable

- The entire table Pad 1000 x 500mm is available for inserted tables

- More room for function modules such as. e.g. Large rotation axes, CardMaker, etc.

- Alternative edits by dividing right/left station.

- Automated flow through control technology integration of the double table

In addition, the double extension table module offers the possibility of loading and unloading one table at a time simultaneously with the marking process.

High productivity

In addition, the double Extract table module offers the possibility to carry out the assembly and removal of one table simultaneously to the marking process.

This enables high throughput to be achieved for processing large quantities.

The sturdy and powder-coated steel construction of the protective cabin is designed for long-term industrial use.

All components required for operation are included in the basic version.

Big tumble

The upward sliding tumble is large in size to allow optimum access to the working space.

To reduce off-peak times, the door's stroke can be limited by the control to eliminate unnecessary Leerwege.

A generous, CE-certified Laser Protection window provides insight into visual process observation.

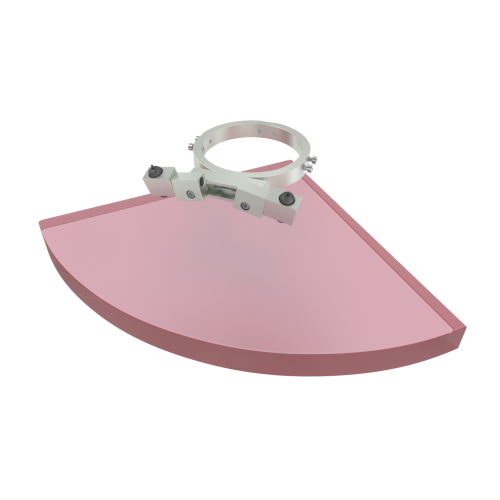

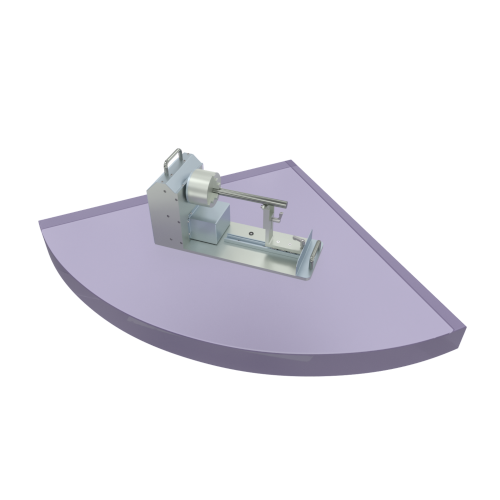

Variant with manual X-y axis

The laser workstation LG300 is most commonly equipped with Mindstens 3 NC-controlled axes x, Y and Z.

In some cases, such as for the labeling of large workpieces in only one position, a simpler and more cost-effective solution is more advantageous.

Simply adjustable, manual x and y axes with measuring scale are available for this purpose. A high repeat accuracy is ensured by grid positions.

Consistent product tracing

In interaction with the PENAPP track ' n Trace a consistent system for product tracing can be installed, which takes into account the customer-specific requirements.

Complete Package

Included is the PENTEQ software package with graphics editor.

The texts to be labelled can be entered easily and graphics can be compiled or drawn with a mouse click.

Furthermore, an import function for logos or graphics from various formats such as:. dwg;. dxf;. HPGL;. svg and Bitmap is available

Download Product Catalogue:

| Dimensions of working space: (WxDxH) | 1000 x 500 x 300 mm |

| Dimensions: (WxDxH) | 1200 x 1510 x 2200 mm |

| Simple Labeling Range: | 150 x 150 mm |

| Maximum weight of the workpiece: | 100 kg |

| Laser Smoke Extraction: | Integrated |

| Weight of the system: | 580 kg |

| Laser class: | 1 |

| Axis | ||

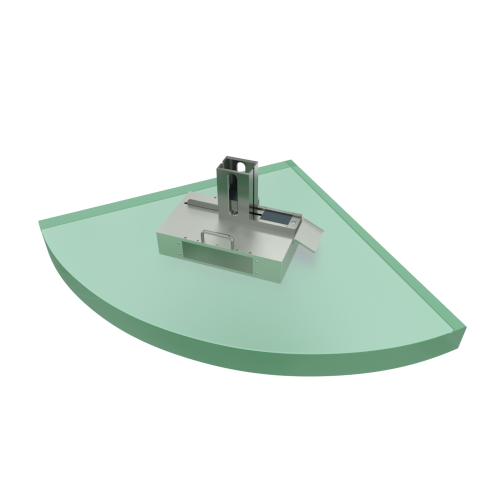

| Pull-out table | ||

| Labelmaker | ||

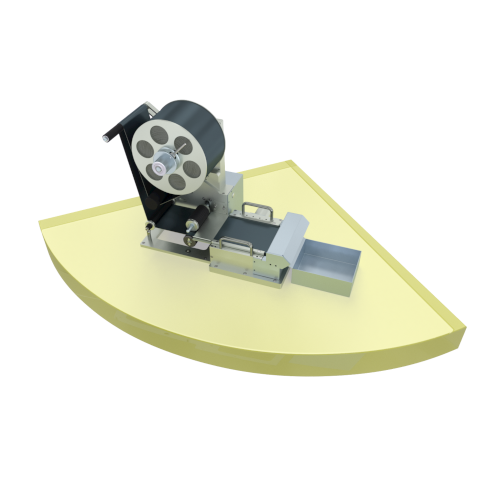

| Cardmaker | ||

| Double Pull-out table | ||

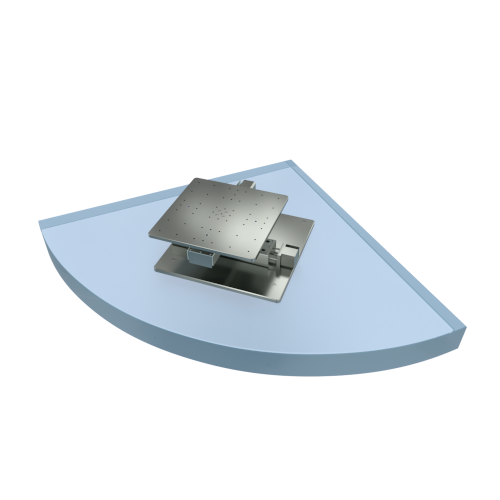

| X/Y Table | ||

| Robot handover | ||

| Linear Conveyor | ||

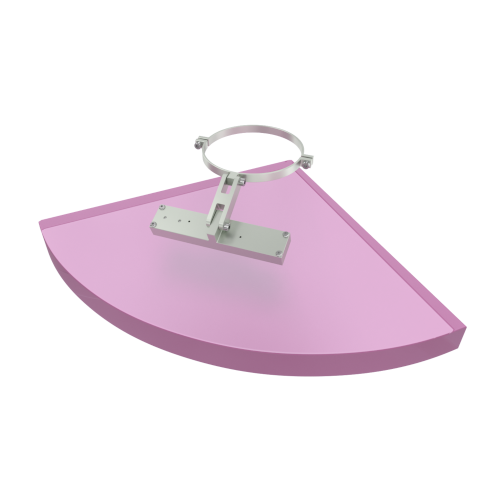

| Ring Conveyor |

| Observation camera | ||

| DMC Camera | ||

| Pilot Laser | ||

| Laser Smoke Extraction | ||

| Focus Finder | ||

| X-Axis Manual | ||

| Y-Axis Manual | ||

| Foot | ||

| Monitor on swivel arm | ||

| Handheld scanner for codes | ||

| Touchsreen | ||

| Bad Partsbox | ||

| 3-Stage State light |