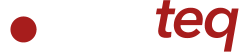

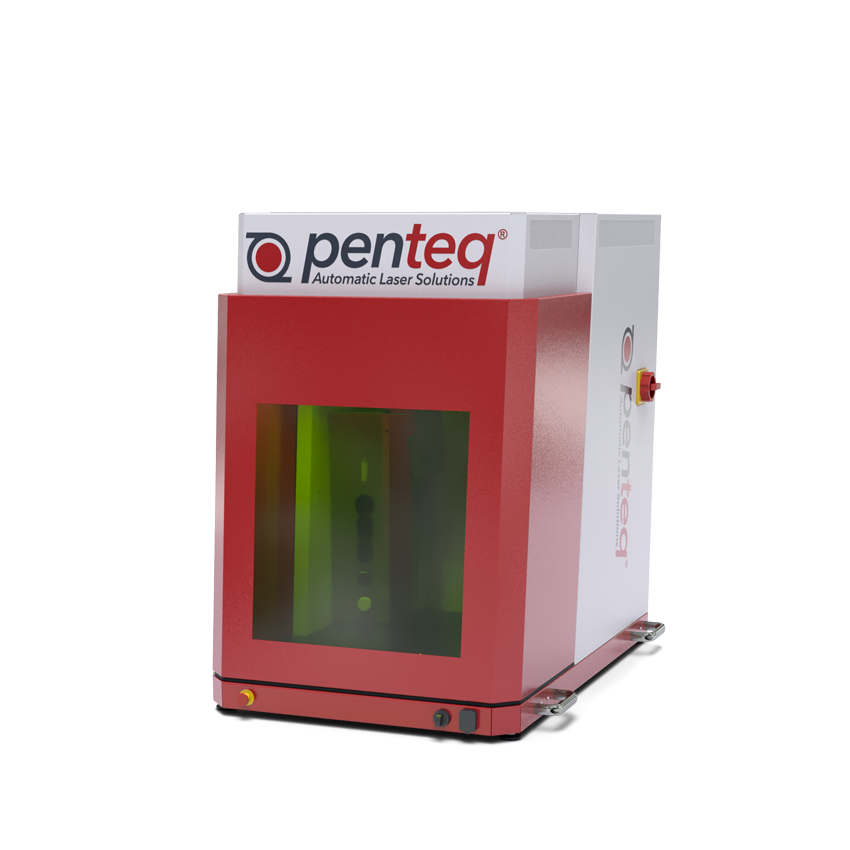

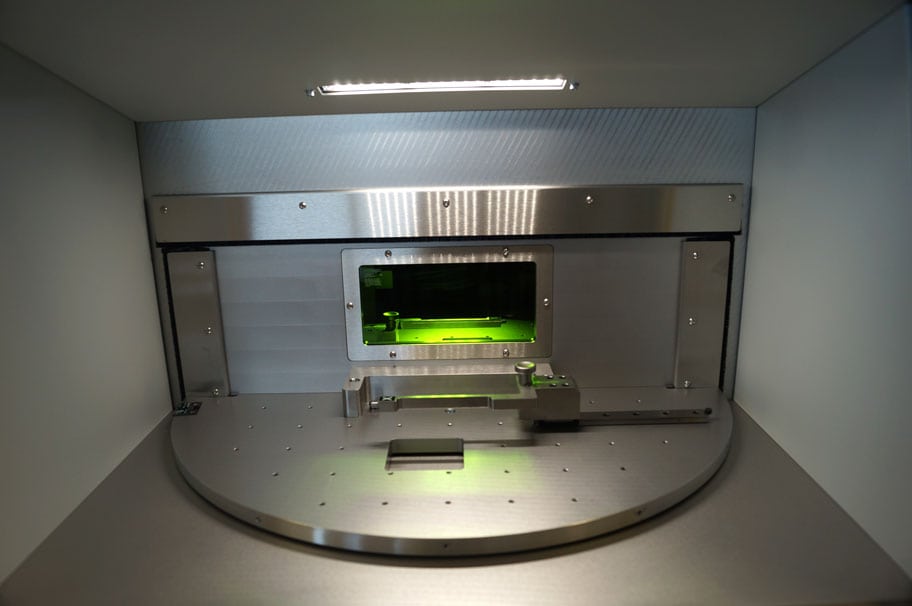

Rotary table-LASER system LG200 RT

Maximum productivity thanks to optimised workpiece handling

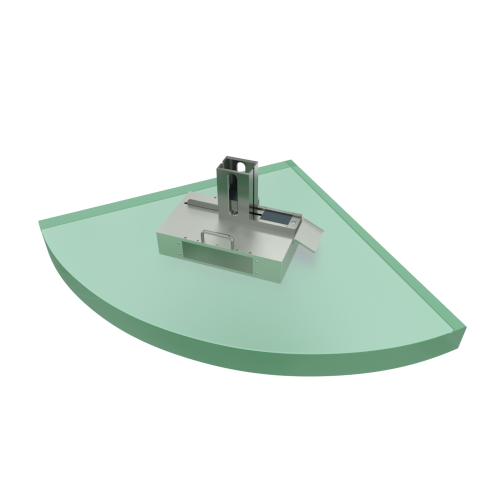

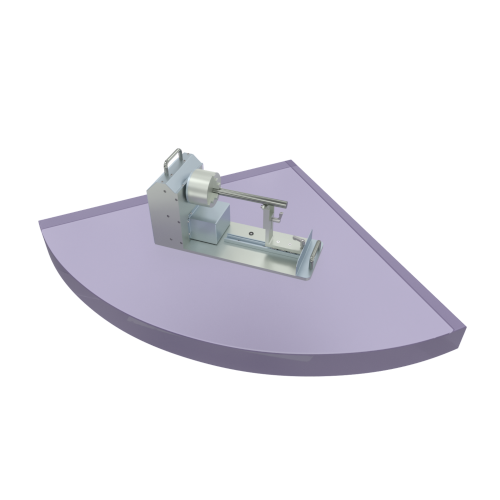

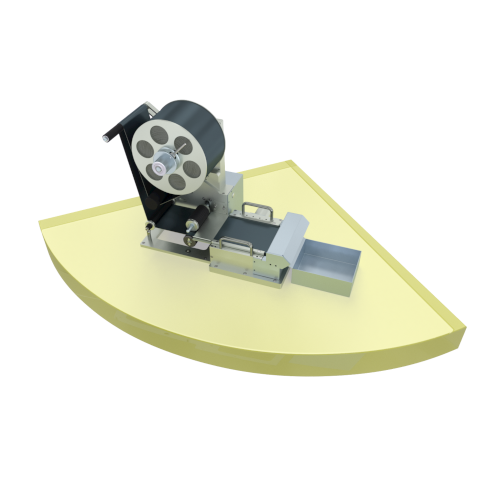

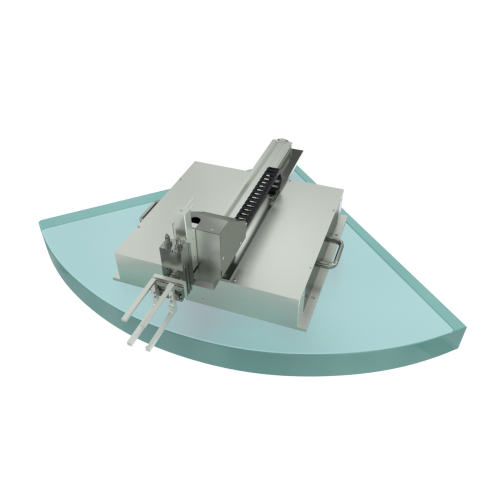

Compact design with integrated, fast-rotating rotary table

Basic system characteristics

- Highest throughput by extraction and assembly simultaneously to the marking process

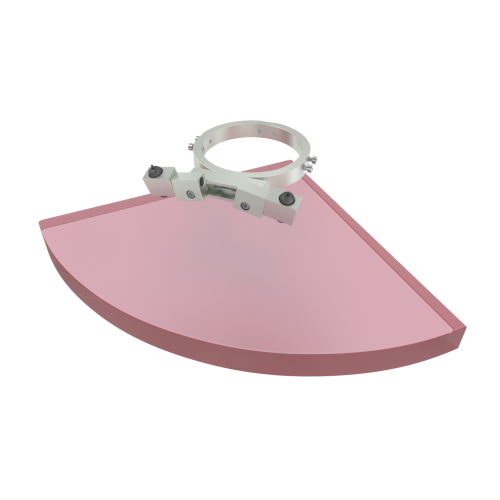

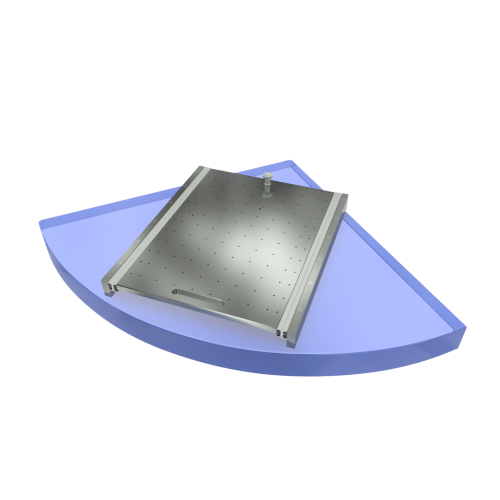

- Compact design with fast rotating 600mm diameter rotary table

- Laser Class 1 including the required smoke extraction

- Automatic loading and unloading room lighting for optimized intuitive operation

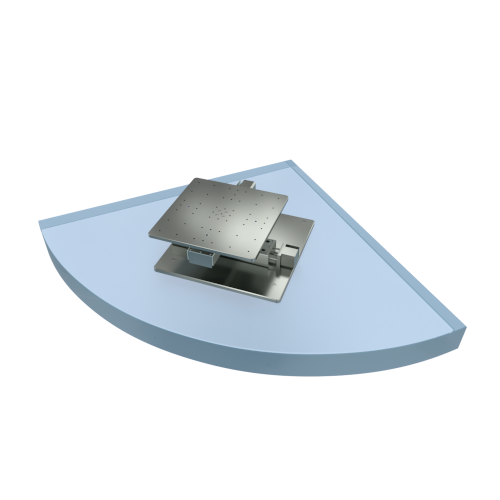

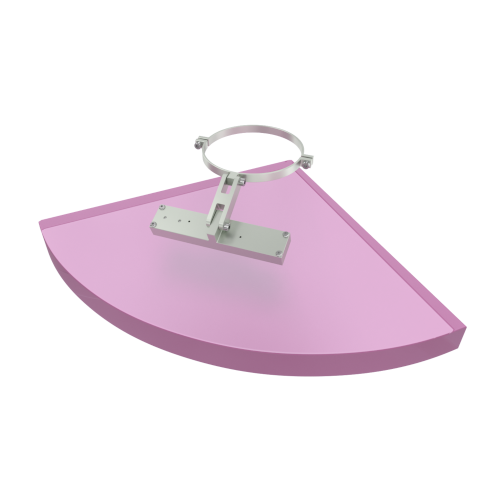

- Center Feedthrough for electrical/pneumatic clamping devices

- Quick-Change device for customer-specific workpiece shots

- Optional camera solutions for reading DMC codes or automatic testing of product properties.

ROTARY TABLE-LASER SYSTEM LG200 RT

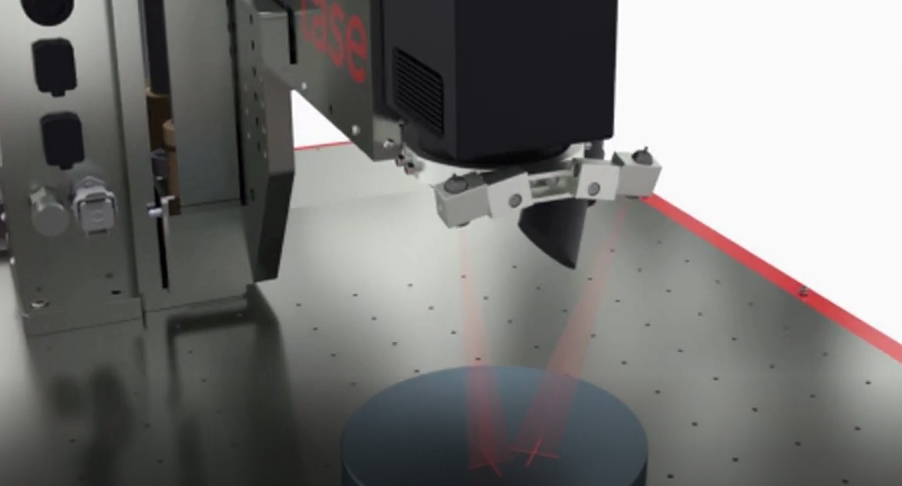

The Penteq rotary table laser system LG200 RT is a compact and user-optimised system of laser Class 1 for the economic labelling of workpieces from different materials such as: steel, stainless steel, aluminium, anodized aluminium, brass and Numerous plastics for highest throughput.

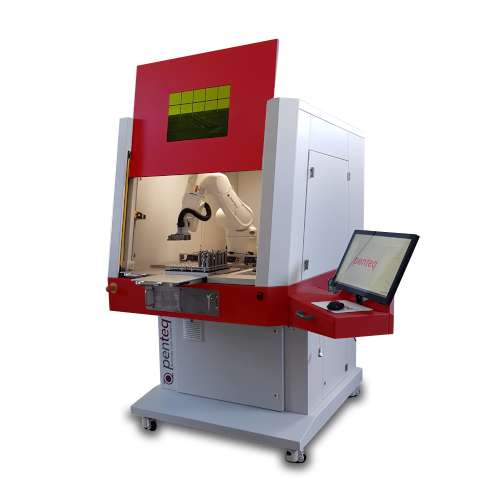

SIMULTANEOUS LOADING AND UNLOADING

In the development of the LG200 RT Rotary Table Laser System, the highest possible productivity was the main focus.

This was achieved by a precise, very fast rotating rotary table. Thus, during the machining process, the removal of the labeled and the assembly with unlabeled parts can take place.

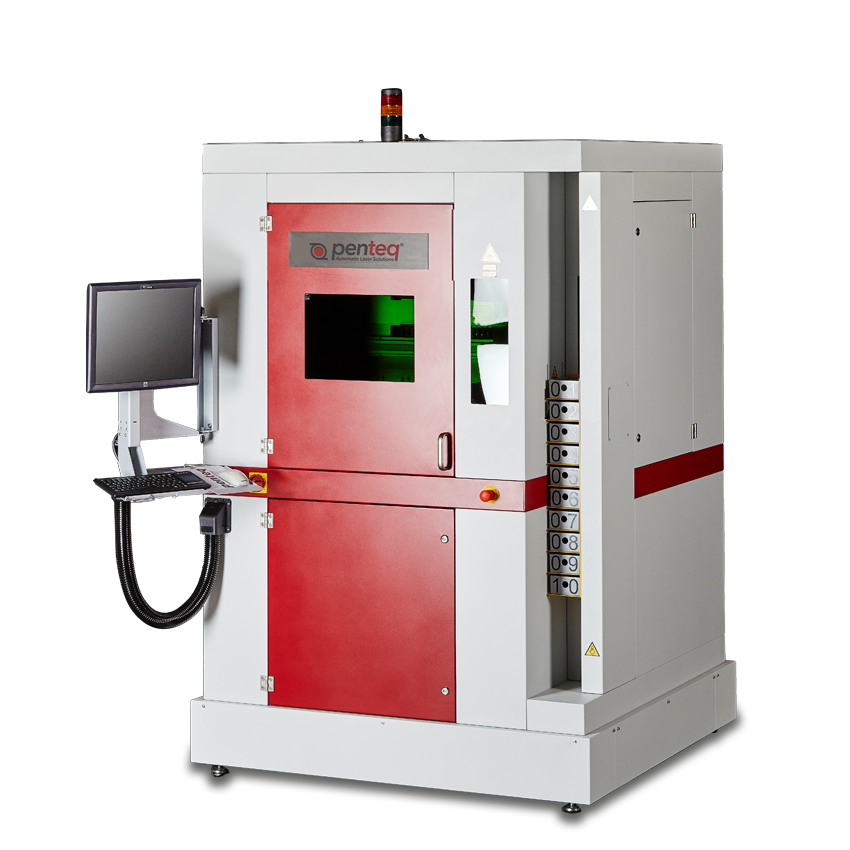

MASSIVE INDUSTRIAL DESIGN:

The robust and powder-coated steel construction of the protective cabin is designed as the complete system for long-term industrial use.

All components required for operation are included in the basic version.

The system has been specially designed for easy operation without prior knowledge.

For example, the desired label contents can be called up automatically by scanning barcodes or QR codes.

ACTIVE ILLUMINATION OF THE HANDLINGBEREICHES

The area for loading and removal with the workpieces to be worked is provided with an active LED illumination.

This encourages intuitive work by displaying readiness for part manipulation.

Continuous Product Tracing:

In interaction with the PENAPP track ' n Trace a consistent system for product tracing can be installed, which takes into account the customer-specific requirements.

Ready for immediate use:

The device is ready for immediate use, only a 230v power connection is required.

An integrated, CE-certified laser protection window allows the user to view the laser room for process observation.

LATERAL LOADING WITH LARGER WORKPIECES:

The right side of the laser housing is designed as a door with integrated safety technology and enables loading with larger and heavier parts.

A built-in CE-certified Laser Protection window gives an insight into the working space for visual process observation.

Complete package:

Included is the PENTEQ software package with graphics editor.

The texts to be labelled can be entered easily and graphics can be compiled or drawn with a mouse click.

Furthermore, an import function for logos or graphics from various formats such as:. dwg;. dxf;. HPGL;. svg and Bitmap is available

Download Product Catalogue

| Dimensions (WxDxH): | 800 x 1300 x 1980 mm |

| Max work piece Height: | 200 mm |

| Max Plant Weight: | 10 kg per side, max. 20 kg Total |

| Z-Achsenverstellbereich: | 0-200 mm |

| Weight: | 450 kg |

| Axis |

| Pilot Laser |

| Laser Smoke Extraction |

| Foot |

| Handheld scanner for codes |