Round Table Laser System LG300 RT

Maximum productivity in large format

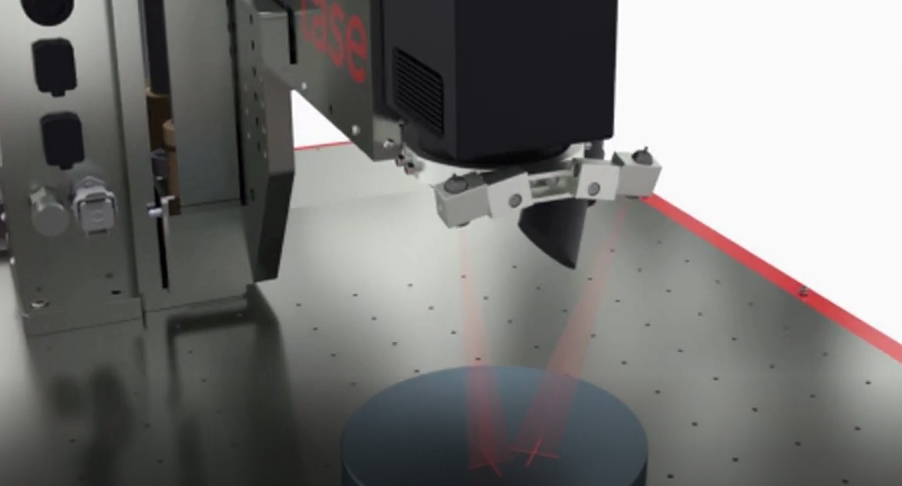

Precise rotary table for machining large parts or many smaller workpieces for high flexibility paired with great economy.

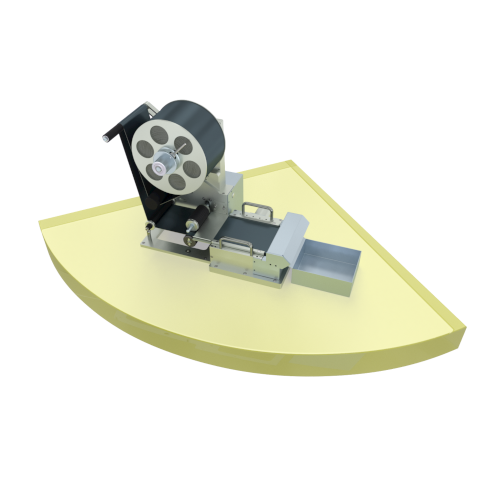

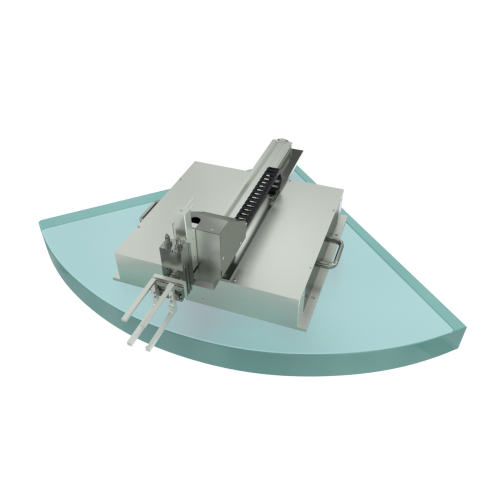

Optionally available axis systems extend the working range and the application possibilities.

Basic system characteristics

- Highest throughput by extraction and assembly simultaneously to the marking process

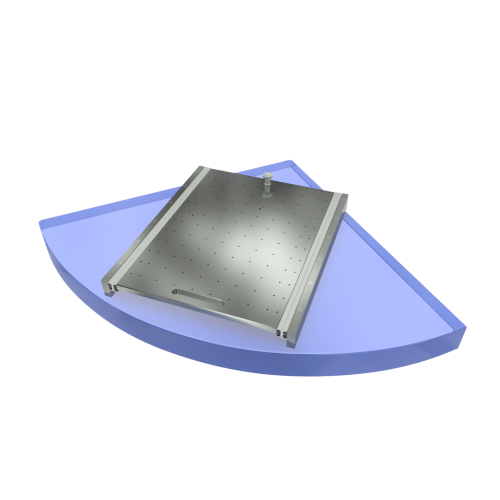

- Large, fast rotating rotary table

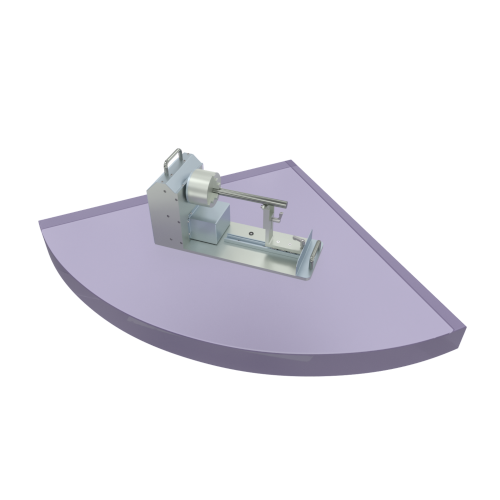

- Expandable with NC-controlled X, Y axes for large working fields

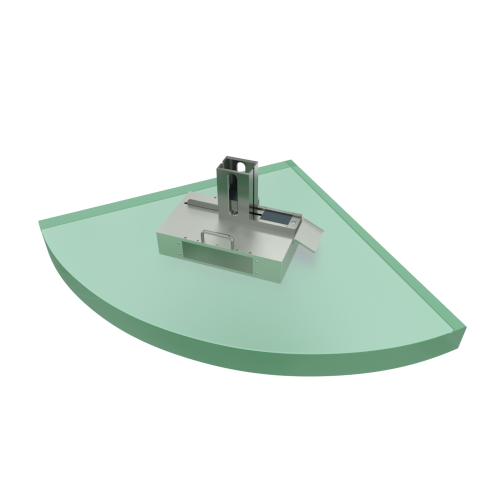

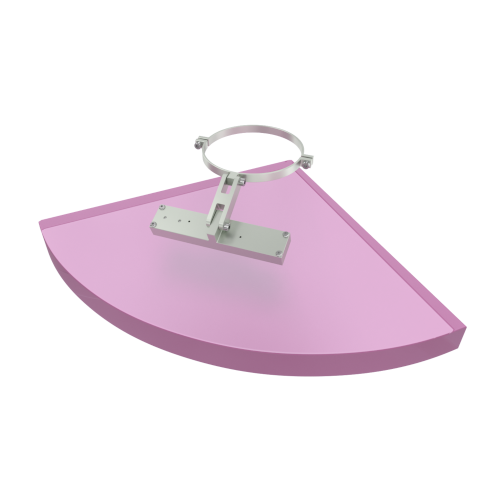

- Rotary axes and swivel axes for special functions

- Laser Class 1 including the required smoke extraction

- Automatic loading and unloading room lighting for intuitive operation

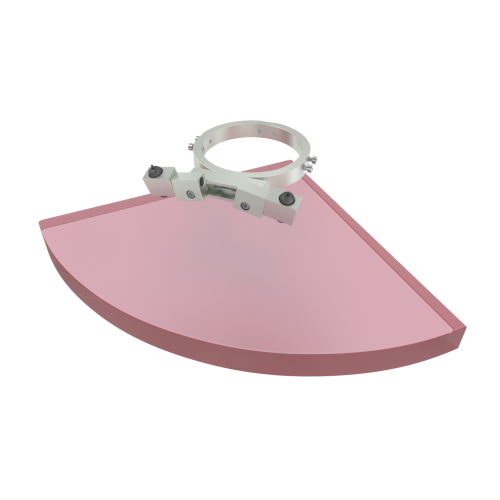

- Center Feedthrough for electrical/pneumatic clamping devices

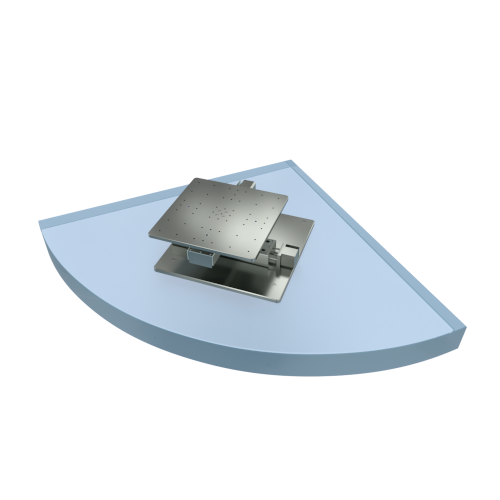

- Quick-Change device for customer-specific workpiece shots

- Optional camera solutions for reading DMC codes or automatic testing of product properties.

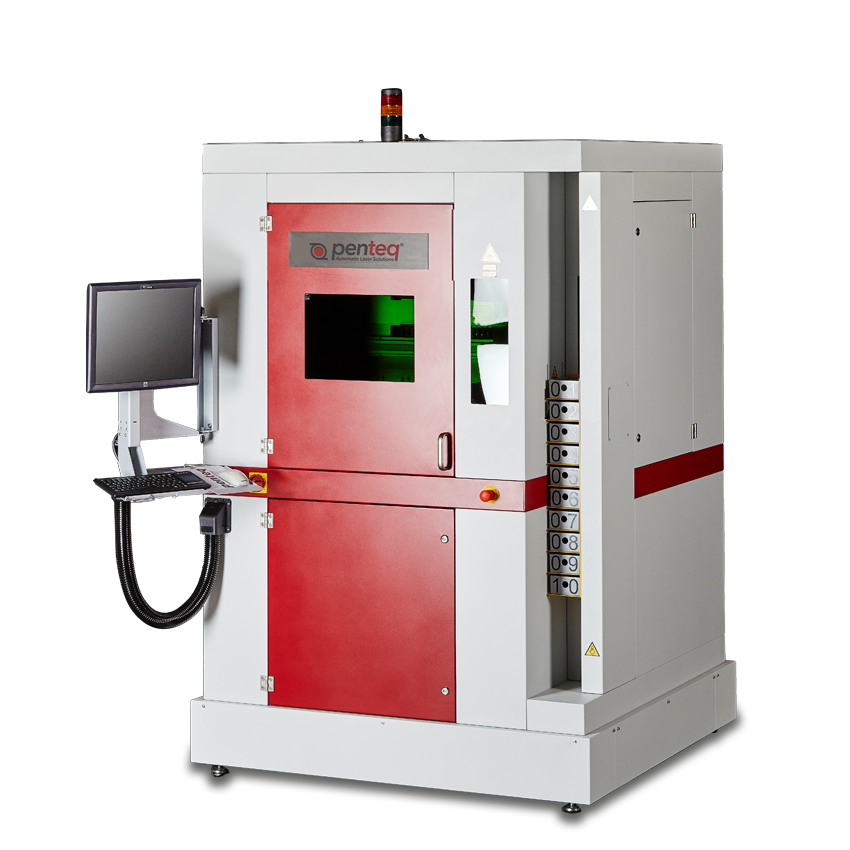

ROUND TABLE LASER SYSTEM LG300 RT

The Penteq LG300 RT rotary table laser system is a user-optimised laser class 1 system for the economical processing of workpieces made of various materials such as: Steel, stainless steel, aluminium, anodised aluminium, brass and numerous plastics for maximum throughput.

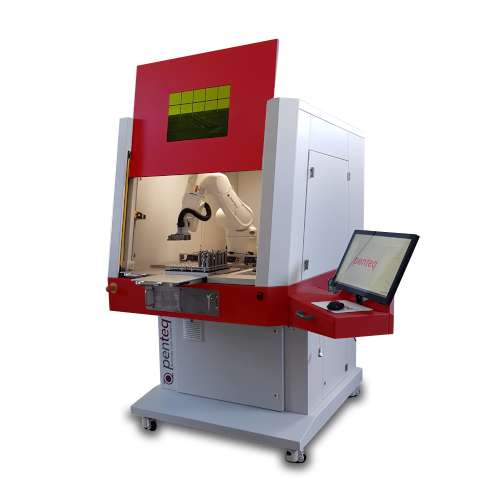

SIMULTANEOUS LOADING AND UNLOADING

When developing the LG300 RT round table laser system, the focus was on achieving the highest possible productivity.

This was achieved by a precise, fast rotating and large rotary table. This allows the finished parts to be removed and nine parts to be loaded during the machining process.

MASSIVE INDUSTRIAL DESIGN:

The robust and powder-coated steel construction of the protective cabin is designed as the complete system for long-term industrial use.

Even the basic version includes all components required for operation. The system has been specially designed for easy operation without prior knowledge...

ACTIVE ILLUMINATION OF THE HANDLINGBEREICHES

The area for loading and removal with the workpieces to be worked is provided with an active LED illumination.

This encourages intuitive work by displaying readiness for part manipulation.

Ready for immediate use:

The unit is ready for immediate use, only a 400V power connection is required.

An integrated, CE-certified laser protection window allows the user to view the laser room for process observation.

LATERAL LOADING WITH LARGER WORKPIECES:

The right side of the laser housing is designed as a door with integrated safety technology and enables loading with larger and heavier parts.

A built-in CE-certified Laser Protection window gives an insight into the working space for visual process observation.

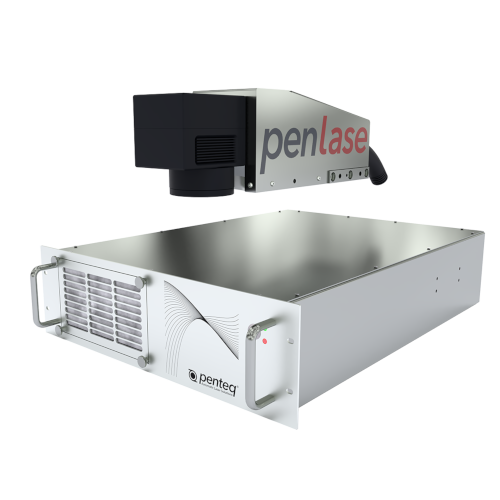

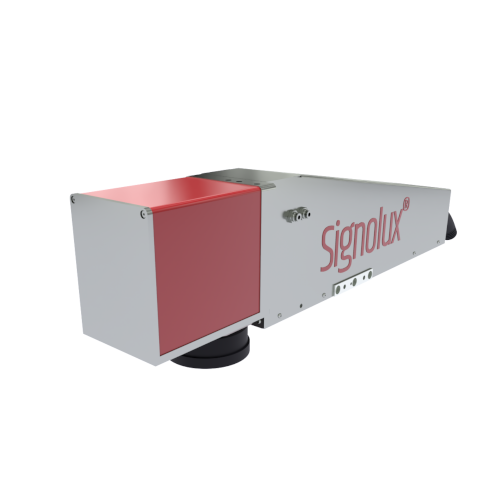

Laser: Fiberline F20,F30, F50, F100, UKP Signolux, Carbonline C30, C60, C120, UV Line, Greenline

| Turntable diameter: | 1000 mm (other sizes on request) |

| Bulkhead height: | 300 mm (other sizes on request) |

| Simple marking field: | 150 x 150mm (other sizes on request) |

| Max Plant Weight: | 25 kg per side, max 50 kg total |

| Z-axis adjustment: | 0-300 mm |

| Weight of the system: | approx. 970 kg |

| Dimensions: (WxDxH) | 1400 x 2000 x 2180 mm |