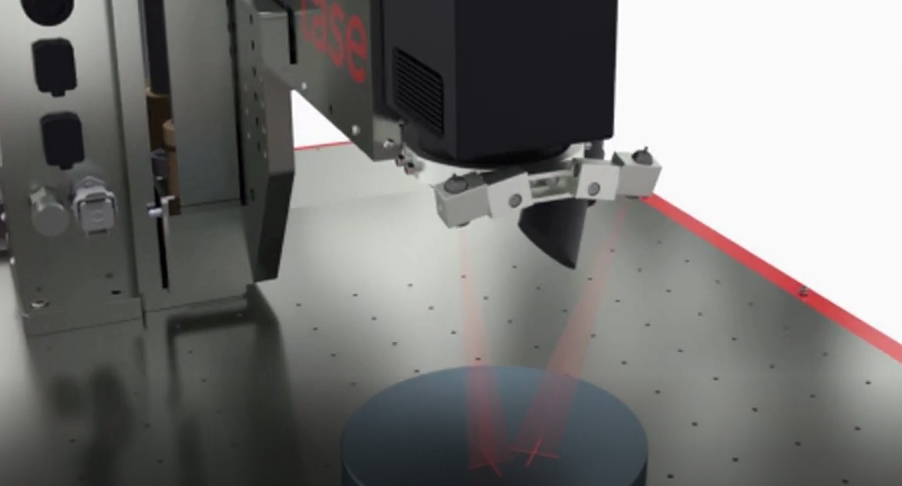

Image processing – Vision systems

The PenVision image processing systems developed specifically for laser applications are divided into the following application areas:

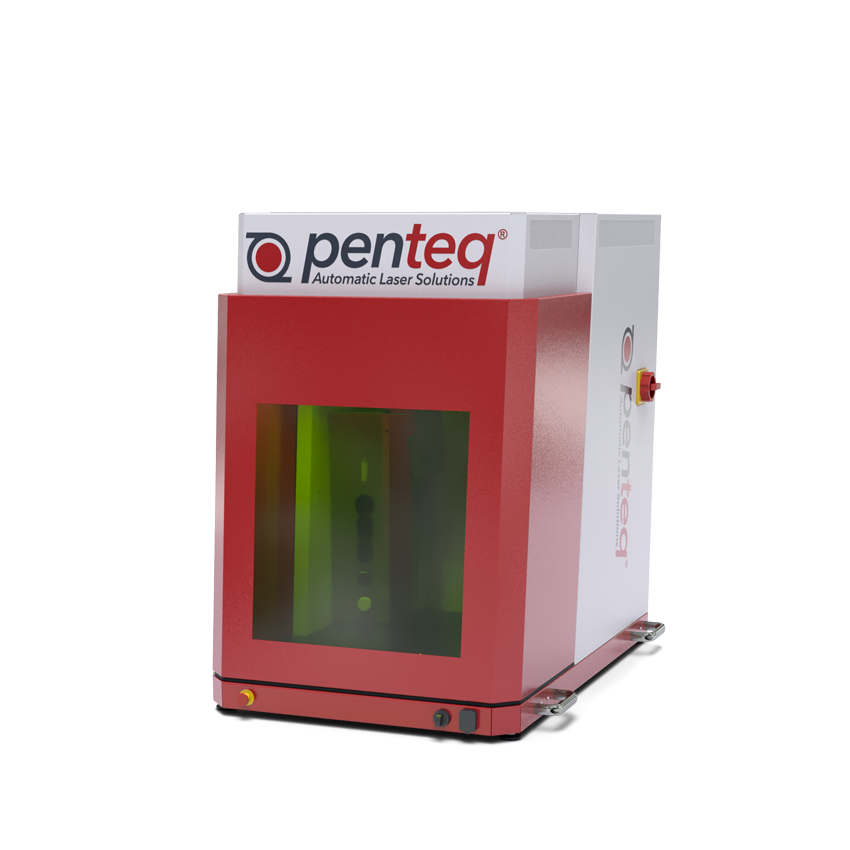

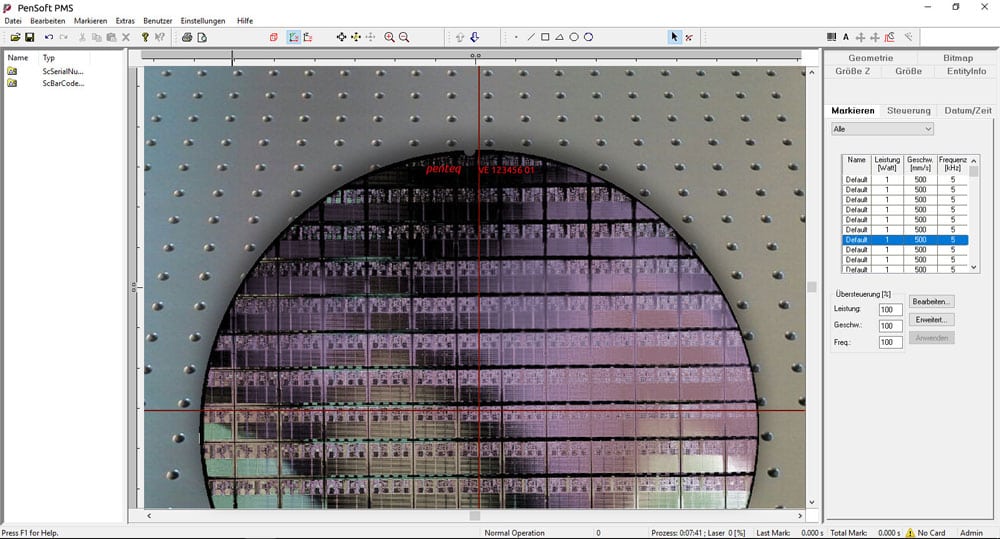

PenVision Smart Adjust:

Reduces the tooling and provides an easy way to accurately position the label layout.

The preview shown in the image shows the result before production.

- Makes precise positioning easier with manual part manipulation

- Reduces production scrap

- Precise marking from Lot size 1

- For small workpieces

- Useful for creating and sizing new layouts

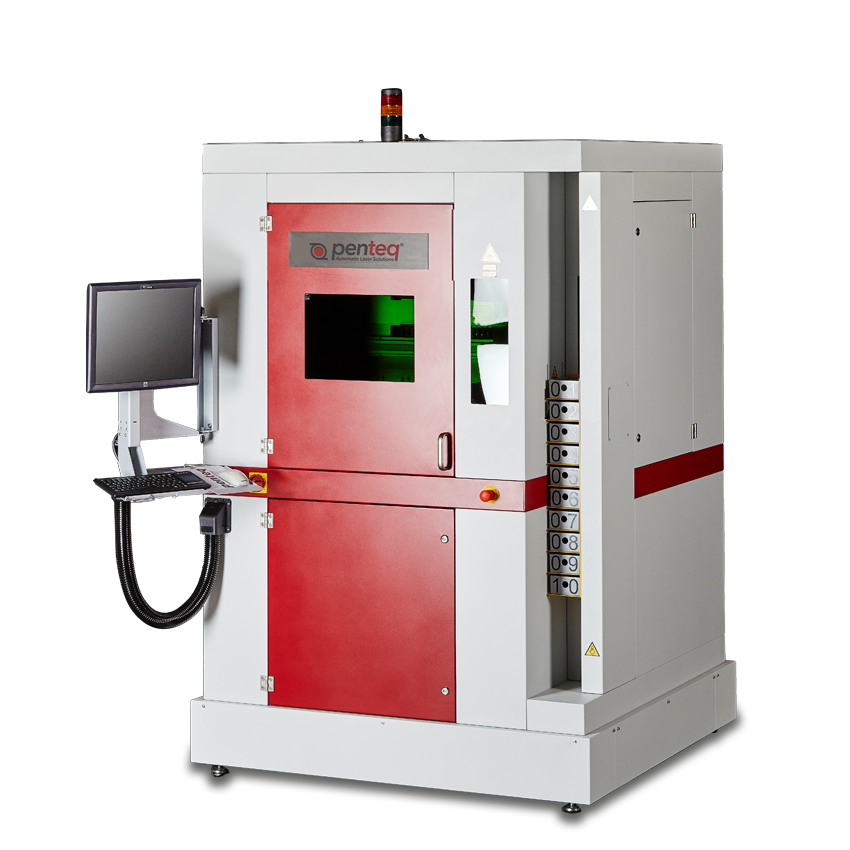

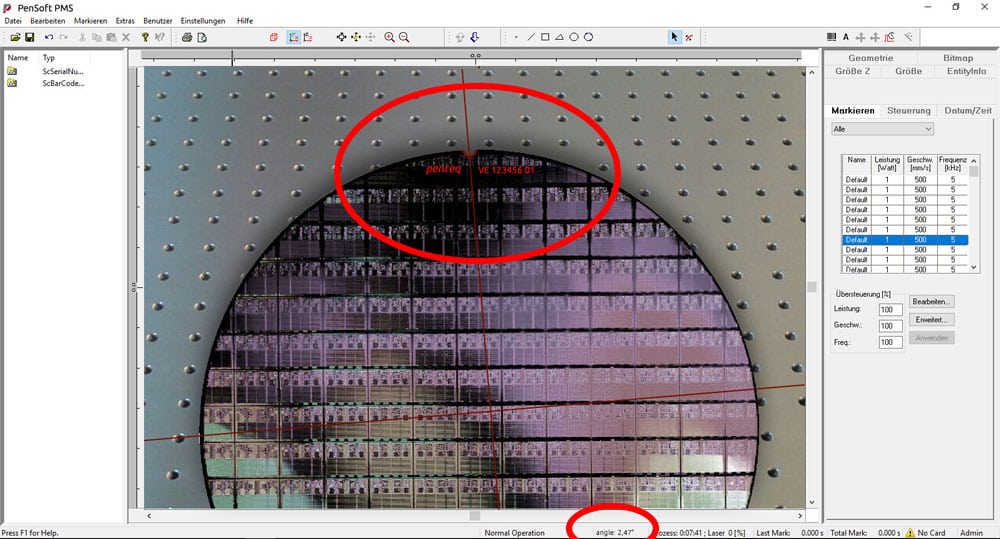

PenVision Automatic mode:

If workpieces are not to be inserted into recordings or the laser process requires a feeder with inaccurate

Positioning, the PenVision automatic mode offers the possibility of automatic recognition of the contours and the alignment of the layout on the workpiece.

- Automatic detection of workpieces

- Avoidance of Production Committee

- Precise markings for workpiece contour

- Correction in position and rotation

PenVision Read and check:

To check the presence and correctness of gelaserter data matrix codes in repetitive manufacturing, PenVision read and check is used.

The code is read out and compared to the content to be reproduced. If the code can be read against and the content is ident, it is evaluated as IO. Unreadable codes are rated NIO and an error message is displayed.

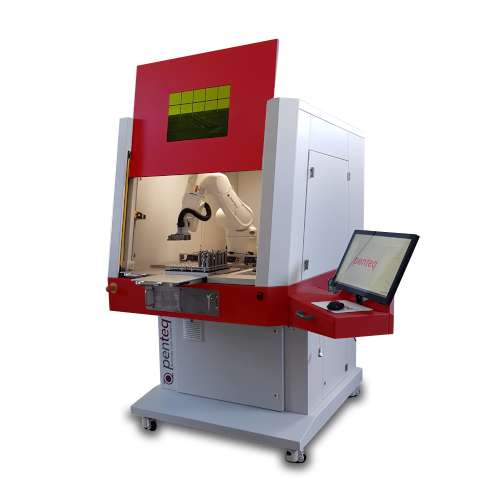

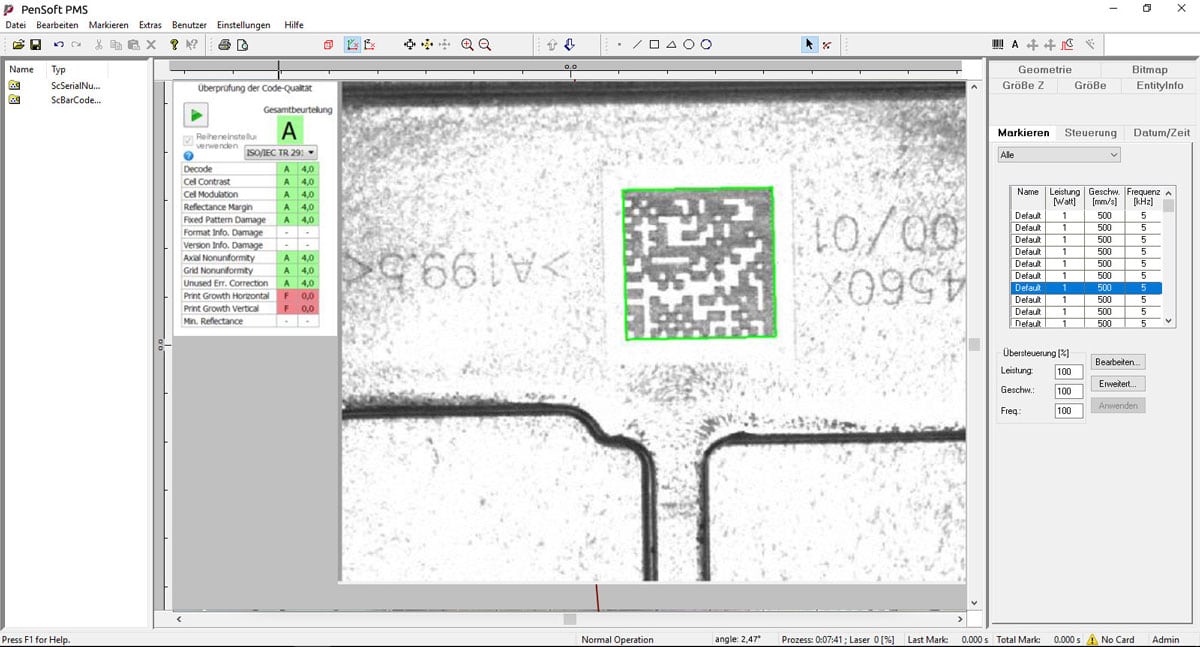

PenVision verifier:

If a standard-compliant quality inspection of applied data matrix codes is required, PenVision Verifier is the solution.

The code is verified under defined conditions according to ISO/IEC TR 29158 and evaluated according to various criteria.

Verification can be performed on any part or in repetitive manufacturing as a sample.

An optional link to an order archive also makes it possible to check the results afterwards.

Upon request, protocols can also be issued for quality verification.

Advantages of the test in the Appendix:

- Consistent, defined ambient conditions

- Optional automatic expiration of labeling and verification

- Saves time by avoiding additional handling

- Automatic error detection in case of a predetermined quality target