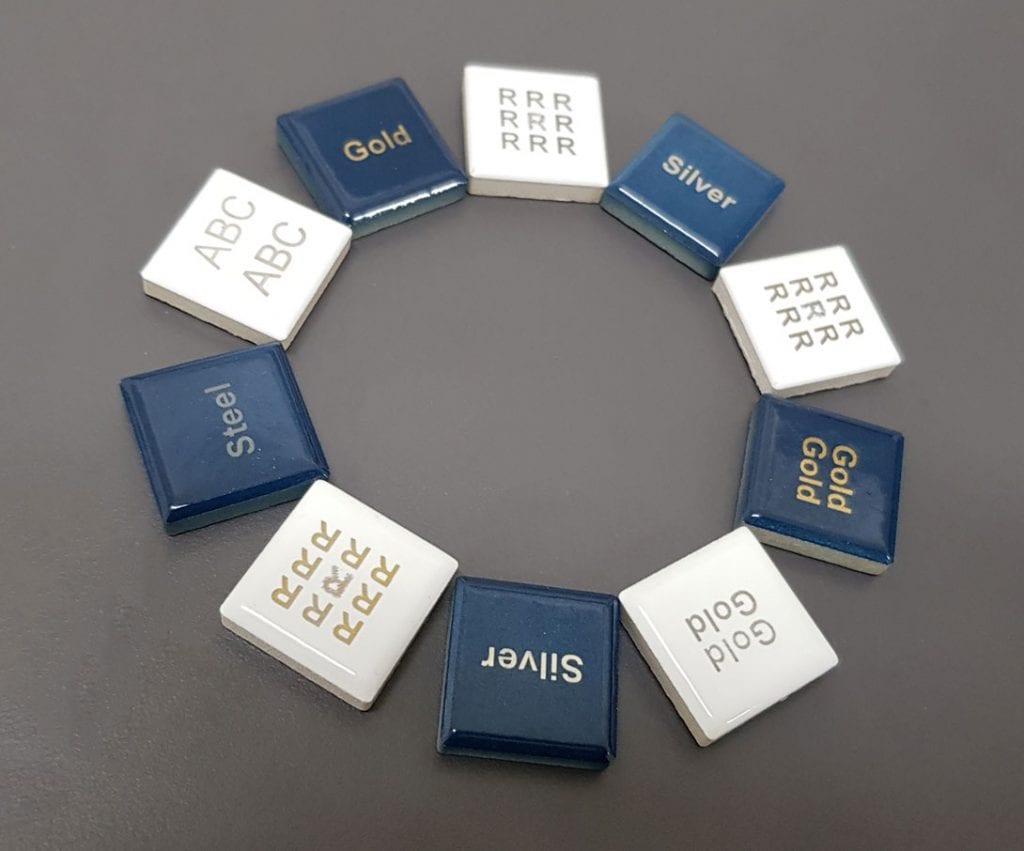

The new alternative for high-contrast, long-lasting labels

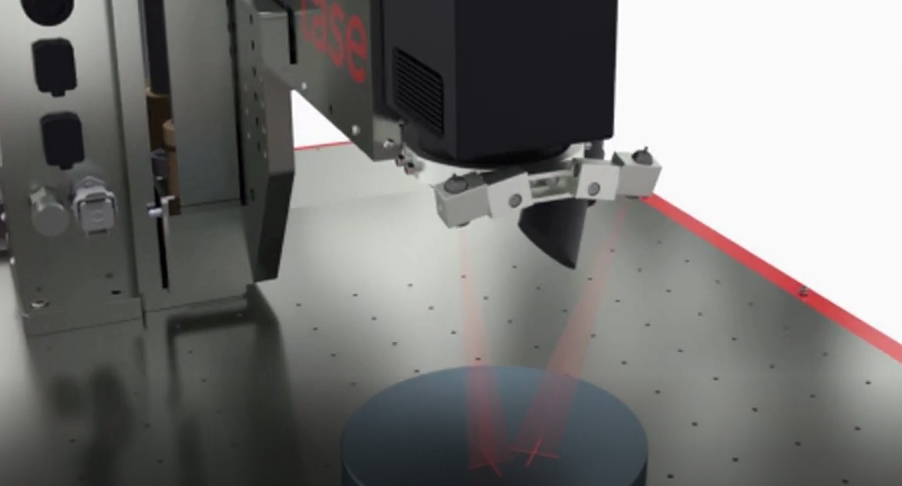

A new process, which is suitable for many different materials, is the additive laser marking (LaseColour).

Conventional laser marking methods like the occasion labeling or engraving have limitations.

High-contrast labels are very dependent on the material properties and are partially unachieveable. Coloured labels are usually not possible at all or only very limited by labeling on certain stainless steels.

Here is the additive laser marking-Laseclour the solution.

Due to the thermal influence of the laser beam, the transfer of special colour pigments is carried out from a transparent carrier to the workpiece surface and with this a chemical-physical connection.

Small layer thicknesses allow a homogeneous image and high-quality, contrast-rich markings.

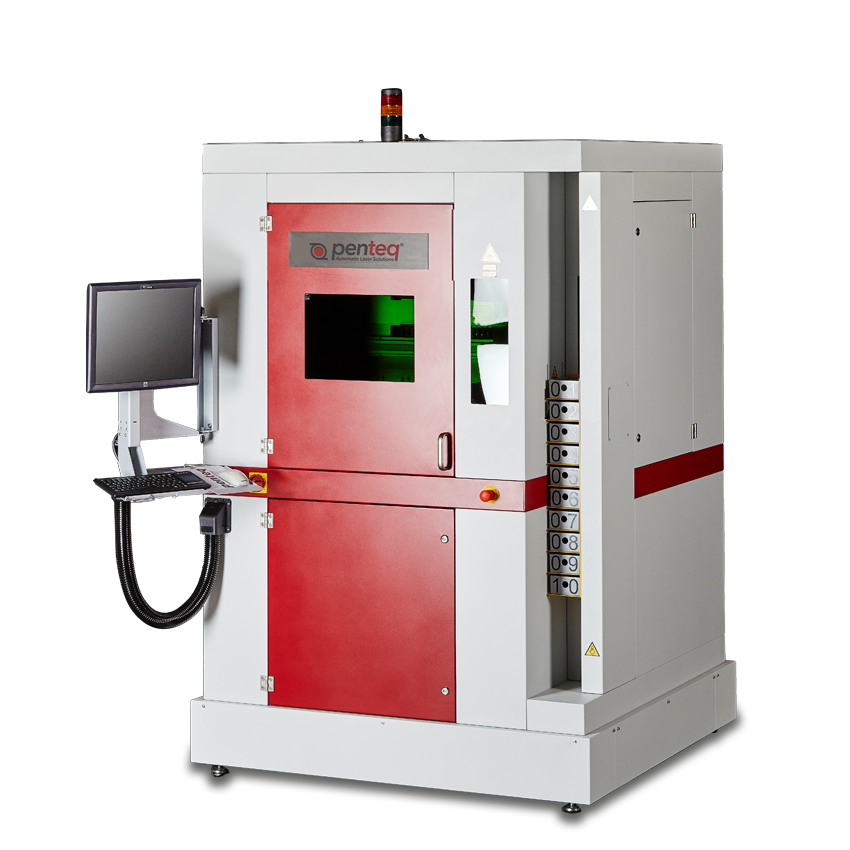

The process is particularly suitable for high-quality products and series production, since the laser additive is specifically developed for every application.

This offers the advantage that exactly the properties required by the user can be included.

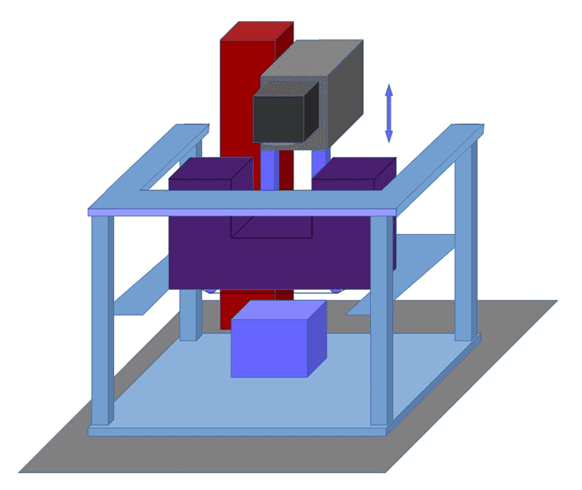

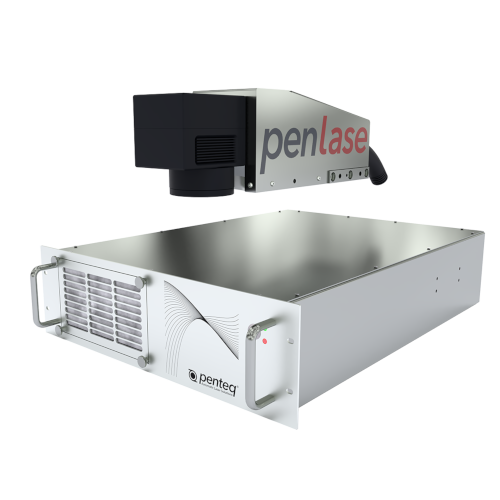

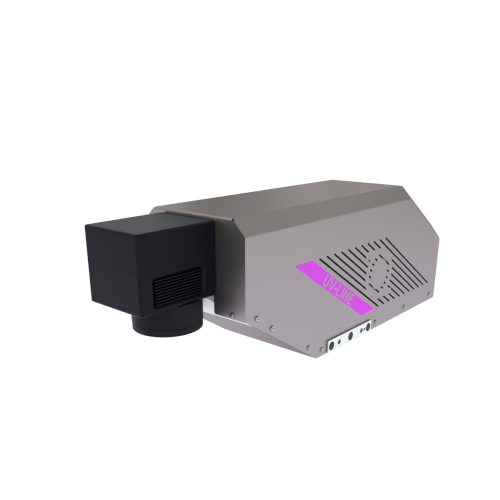

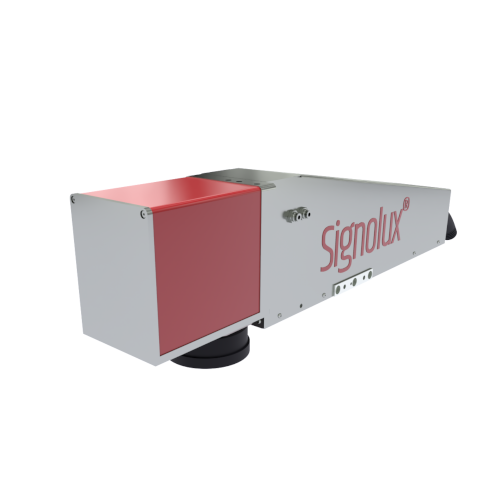

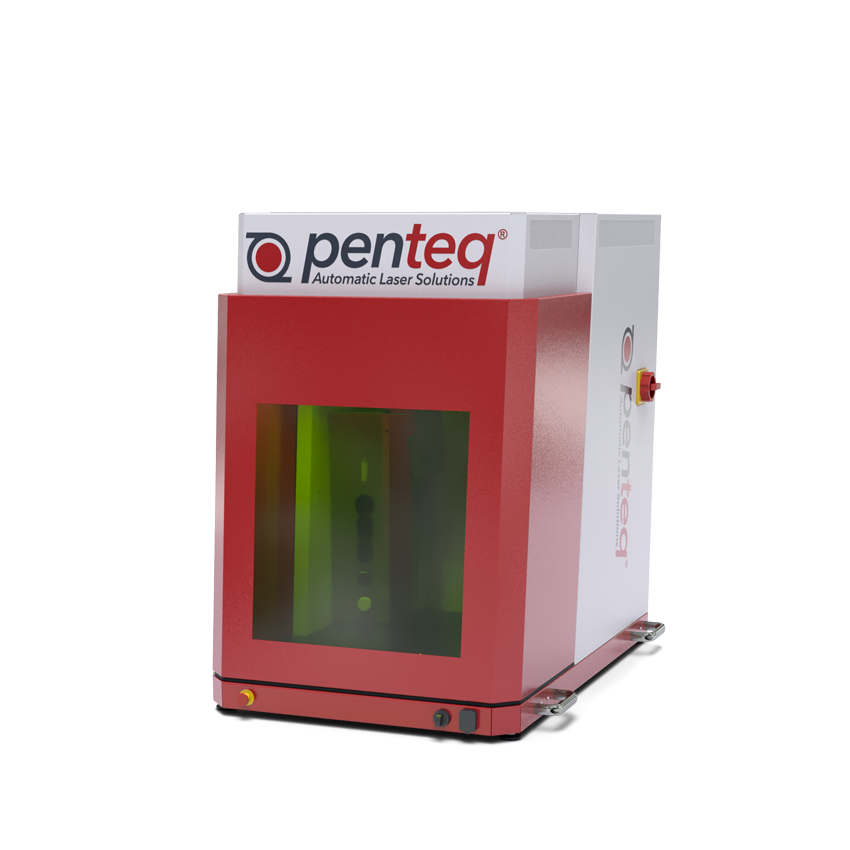

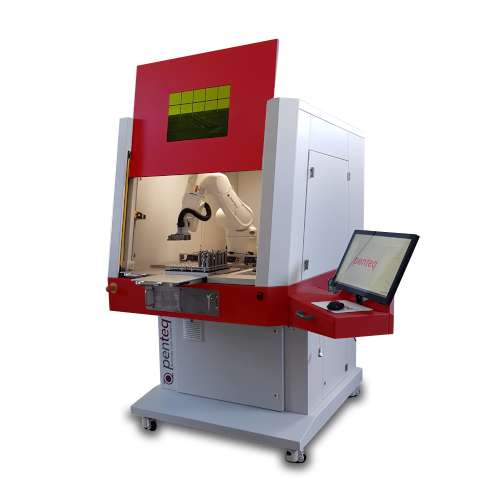

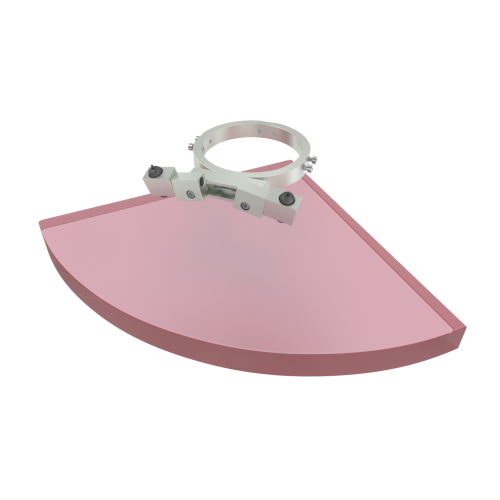

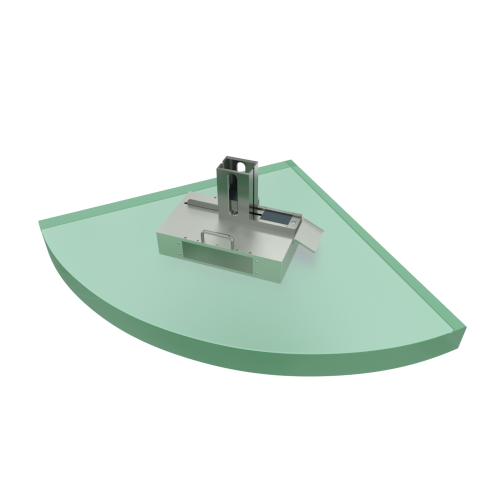

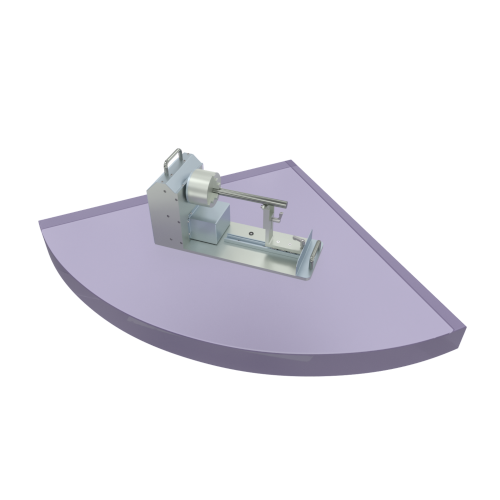

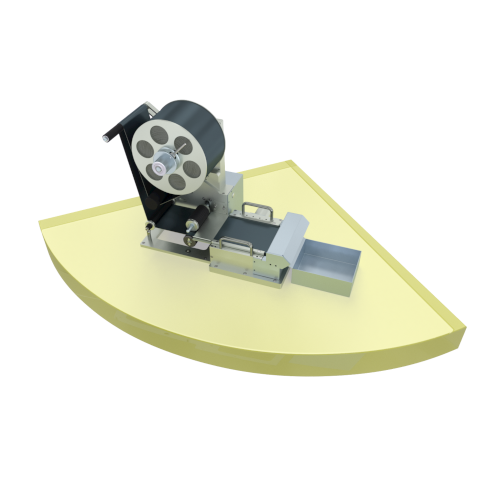

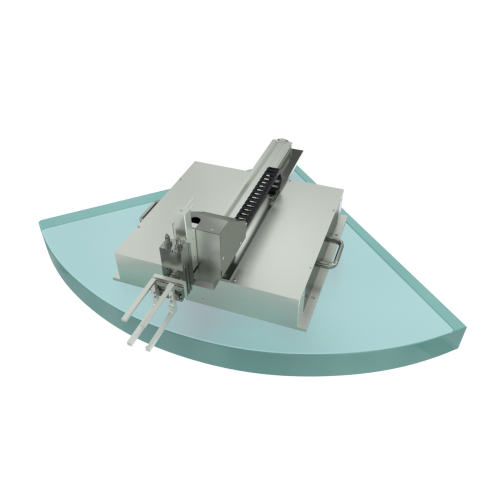

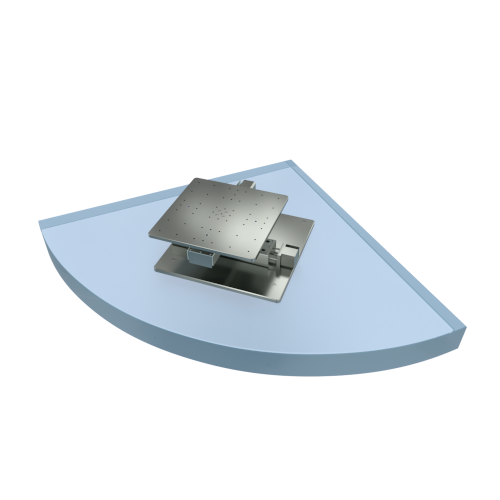

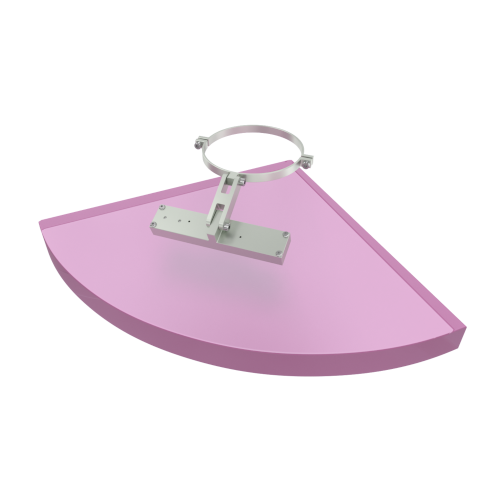

For example, the FM Lasecolour is optionally available for the functional module laser system LG200 and makes it easy to use.

A tool-less changing system also ensures high availability and low off-times and also offers the possibility to easily switch between different colors/layers.