LASER MARKING OF GLASS

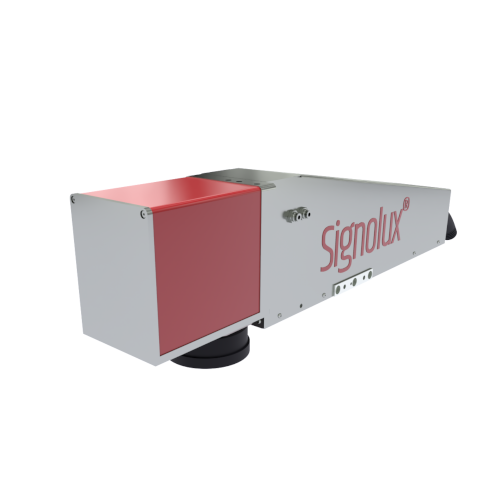

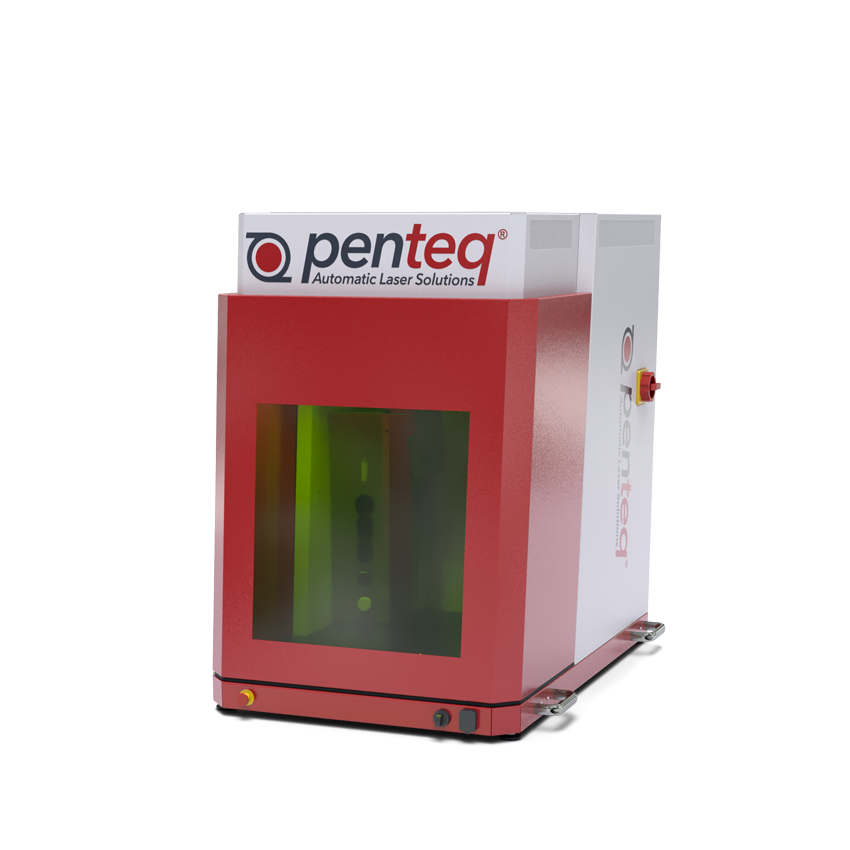

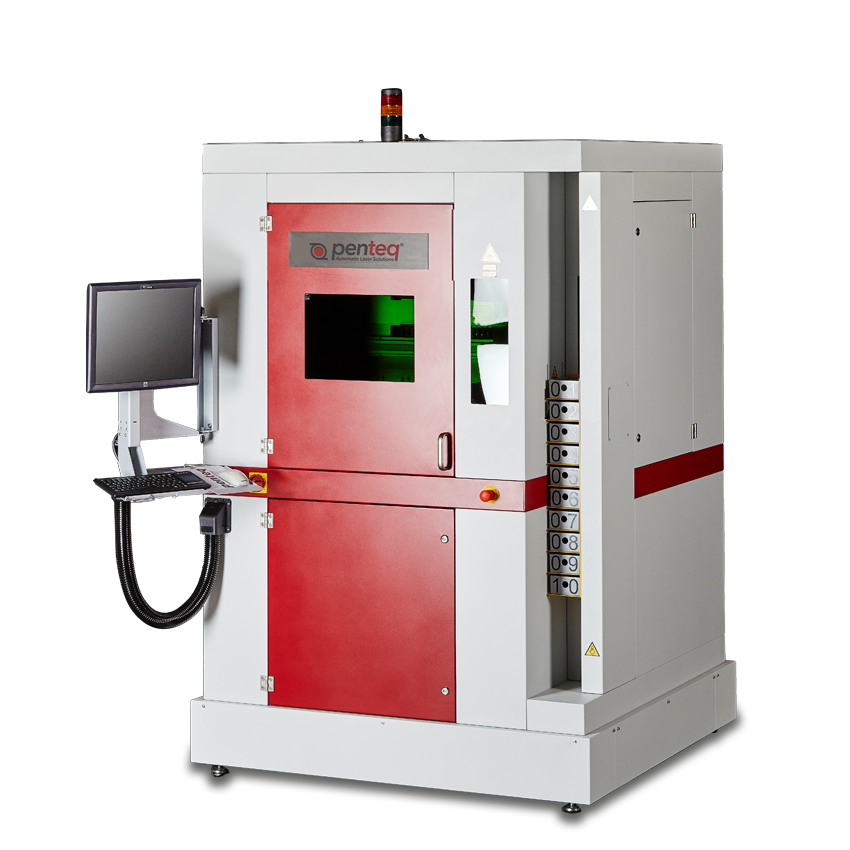

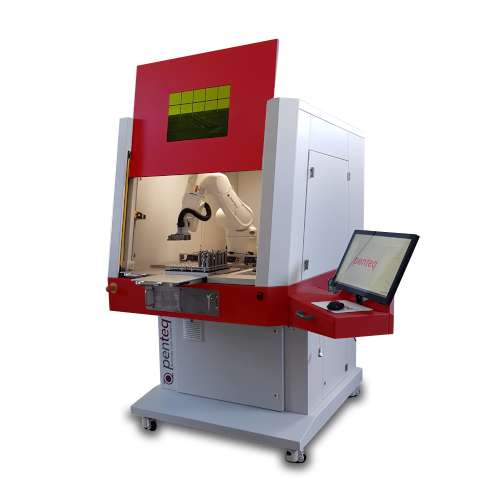

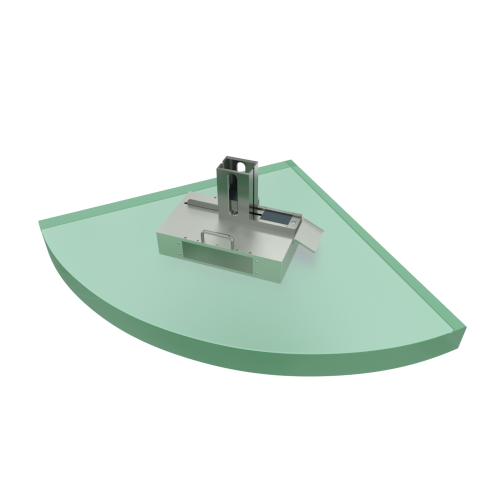

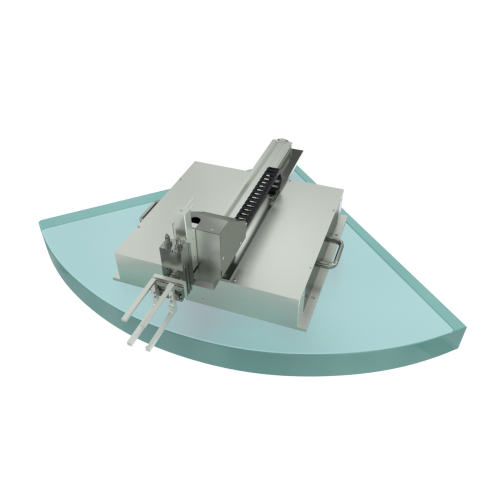

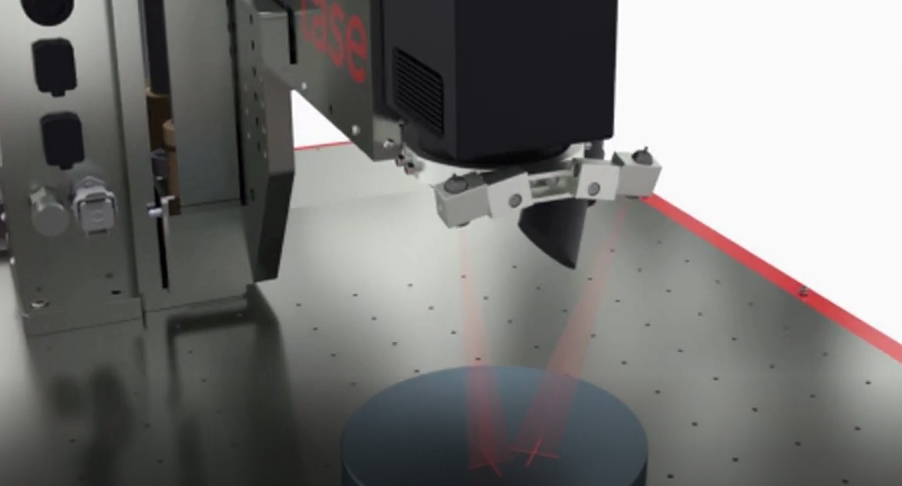

A common process for laser marking of glass surfaces is engraving using a CO2 laser. A high-quality alternative is the new SignoluxⓇ Direct marking.

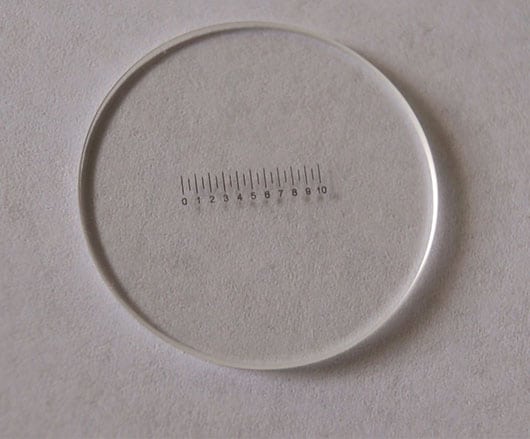

With the Signolux® laser process, direct marking on glass in high quality is possible.

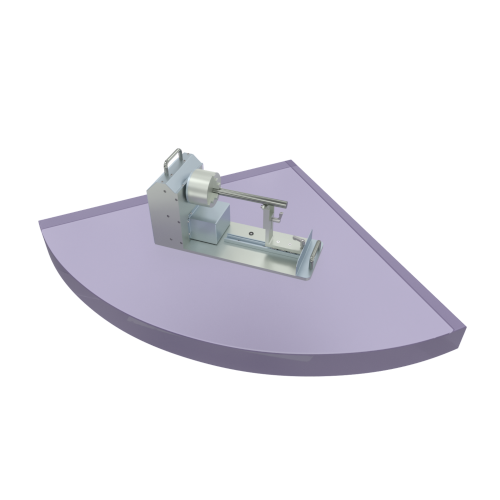

Signolux® is also suitable for the production of data matrix or QR codes as well as logos and represents a high-quality alternative to conventional marking with C0² lasers.

The process produces a uniformly homogeneous marking such as "sandblasted" and sharp contours with high contrast.

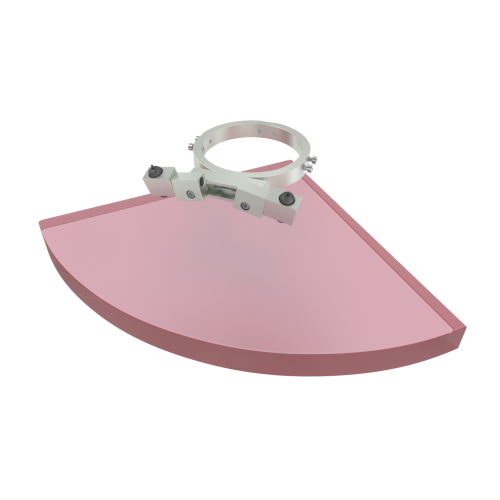

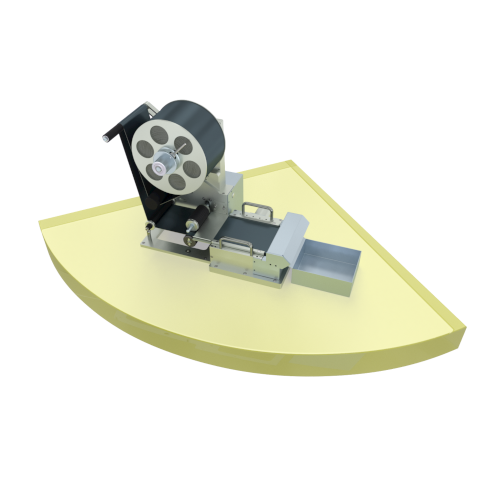

Additive laser marking is a promising technology for achieving high-contrast markings on transparent or smooth surfaces. Due to the thermal effect of the laser beam, chemical processes produce a permanent, additive marking.

Kein anderes Verfahren ermöglicht wie additives Laserbeschriften eine definiert farbige Oberfläche ohne dabei auf Widerstandsfähigkeit, Kontrast und Haltbarkeit zu verzichten. Additive Lasermarkierungen sind beständig gegen Abrieb und Umwelteinflüsse und damit dauerhaft haltbar.