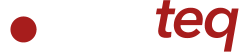

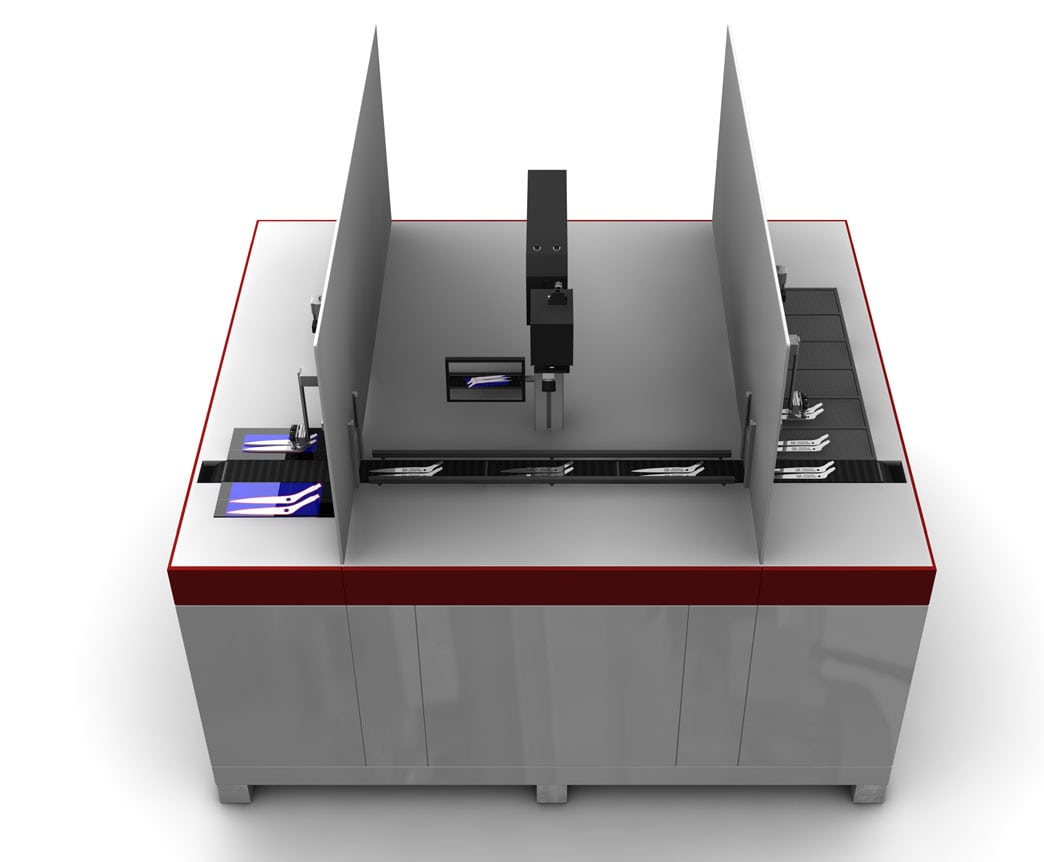

Laser marking system for parts

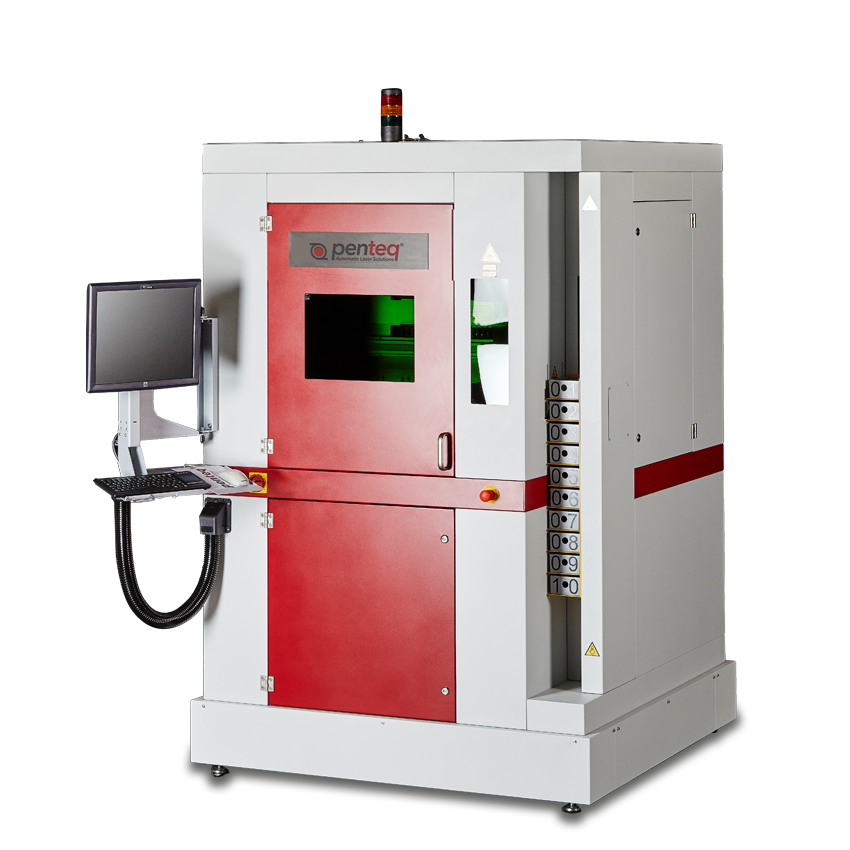

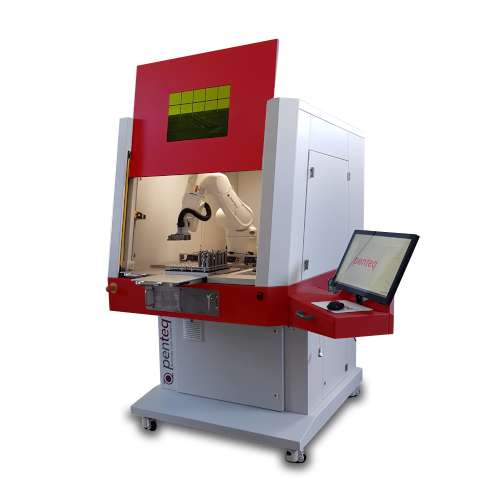

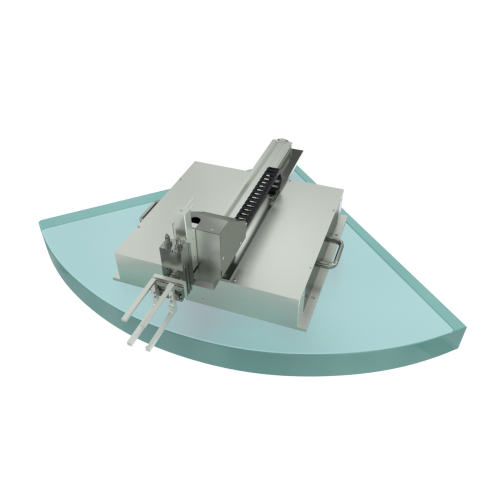

Automatic laser system for high throughput with 2 insertion positions for simultaneous loading.

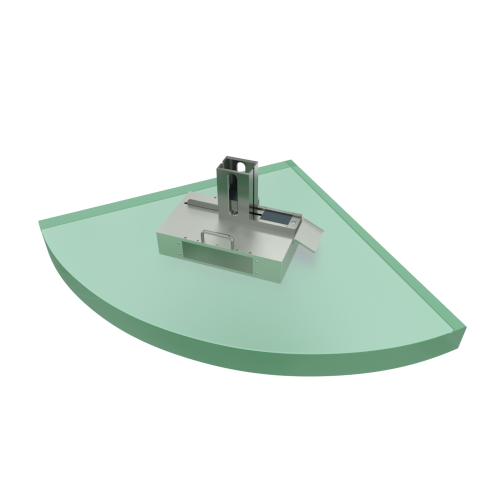

Characteristics of the basic system:

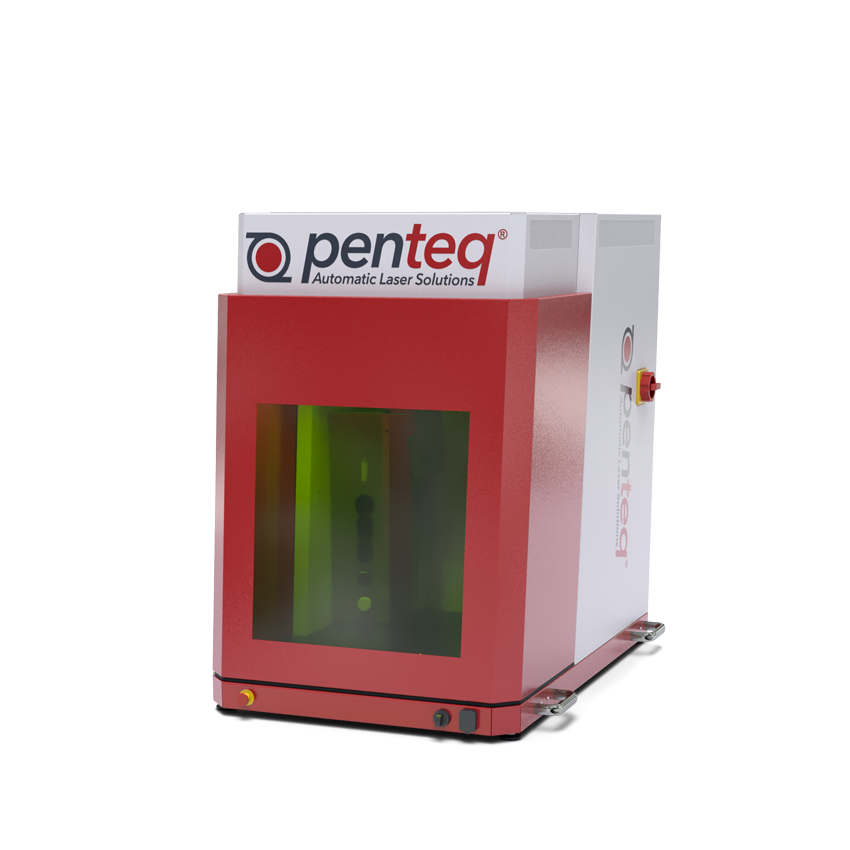

- Laser Class 1 through closed housing

- 2 loading stations for simultaneous loading with workpieces

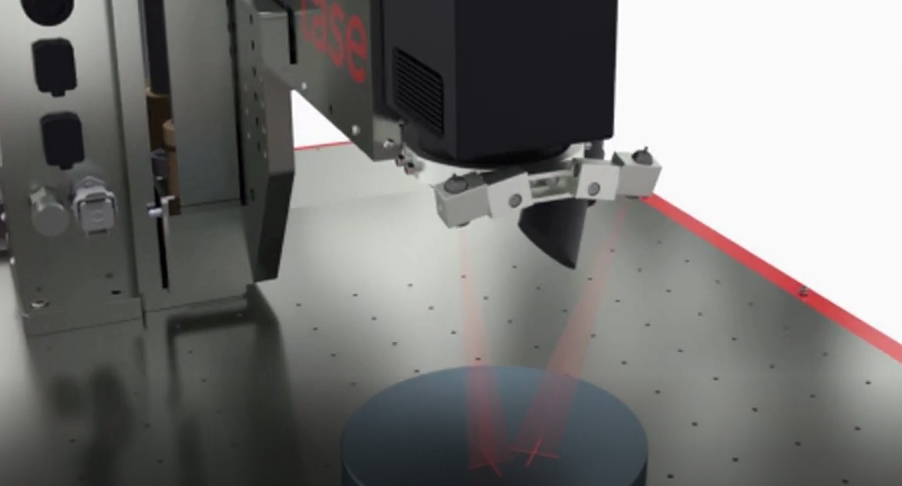

- Integrated vision system for position correction of laser marking

- Connection to ERP systems by standard interface

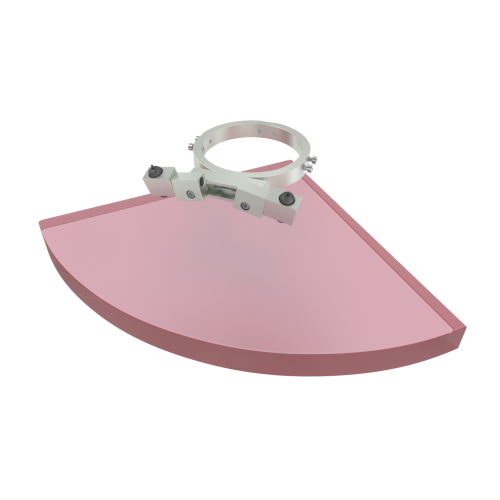

- Generous laser Protection window for process observation

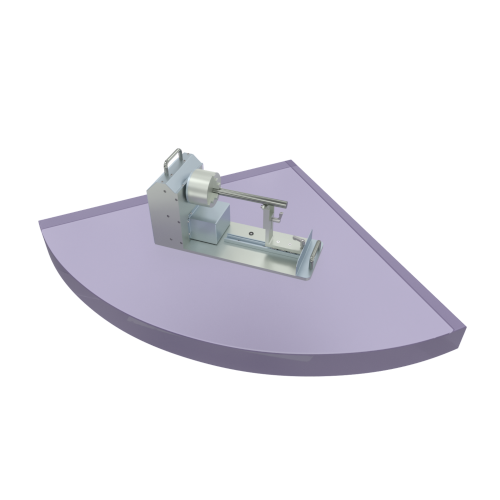

2 stations for loading enable the preparation of the workpieces to be labeled as stacks under the current production by alternating operation.

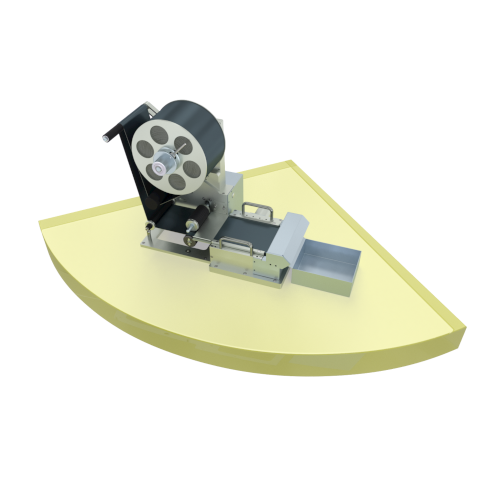

The finished products are sorted on up to 5 stations.

Optical recognition ensures the exact positioning of the label. The workpiece is labelled according to the pattern selected in the program. The pattern can contain alphanumeric content, as well as graphics and logos.

Solid construction

Machine frame in sturdy steel welded construction.

Machine table with 2 insertion stations equipped with screens for the position display of the scissor legs.

Loading and unloading gripper system, as well as an integrated conveyor belt camera for monitoring the shear position Laser Protection Case Laser Class 1 with CE-certified Laser protection Window – suction BOFA incl. filter free to set up.

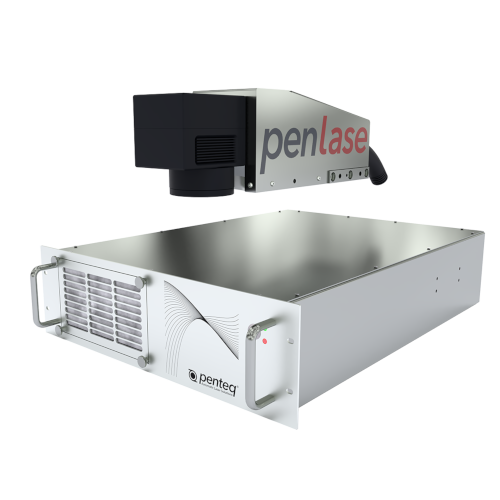

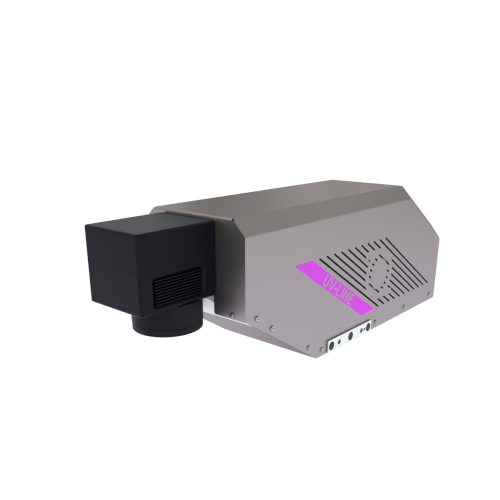

| Laser Medium: | YB: Fiber laser, air cooled |

| Performance: | 20, 30, 50 W |

| Marking field: | 120 x 120 mm |

| Dimensions (LXDXH): | 2300 x 1600 x 1900 mm |

| Weight: | 600 kg |