Options and Accessories:

There are numerous options and accessories available to optimally equip your PENTEQ laser system for your application. Not all options are available for all machine models. One of our competent specialists will be happy to advise you. Only the standard options and the standard accessories are shown here. In addition, Custom Options and Accessories in verschiedenen Varianten verfügbar.

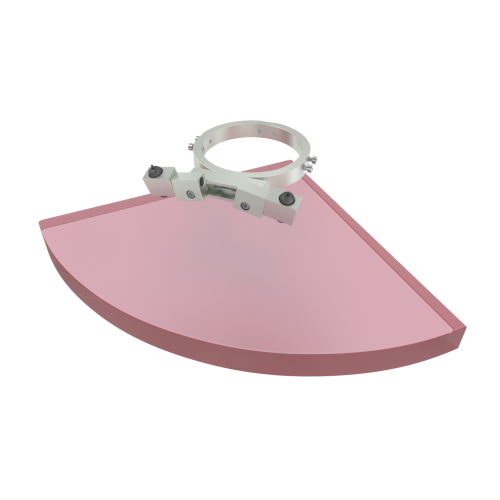

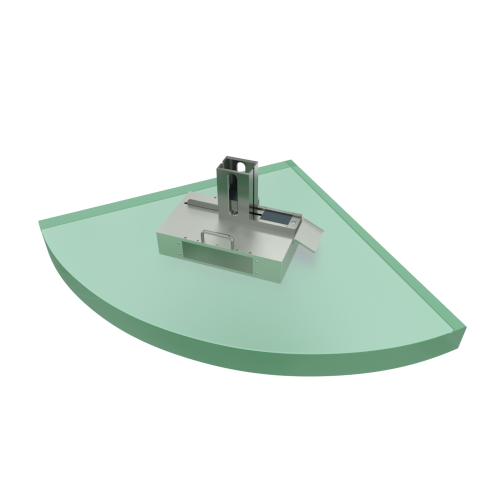

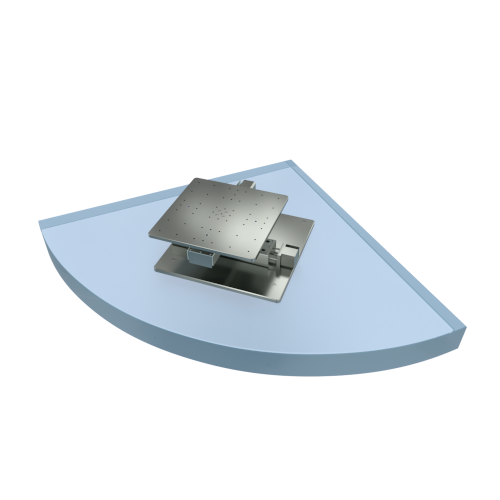

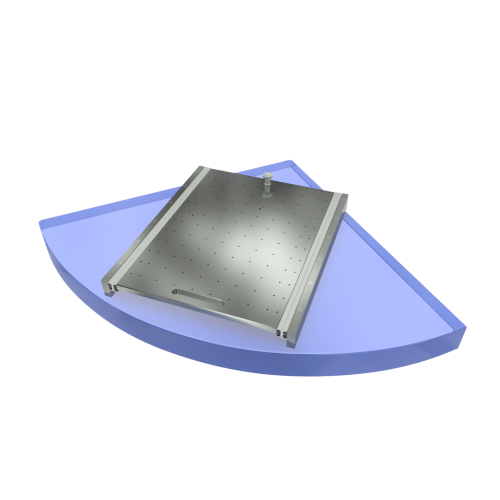

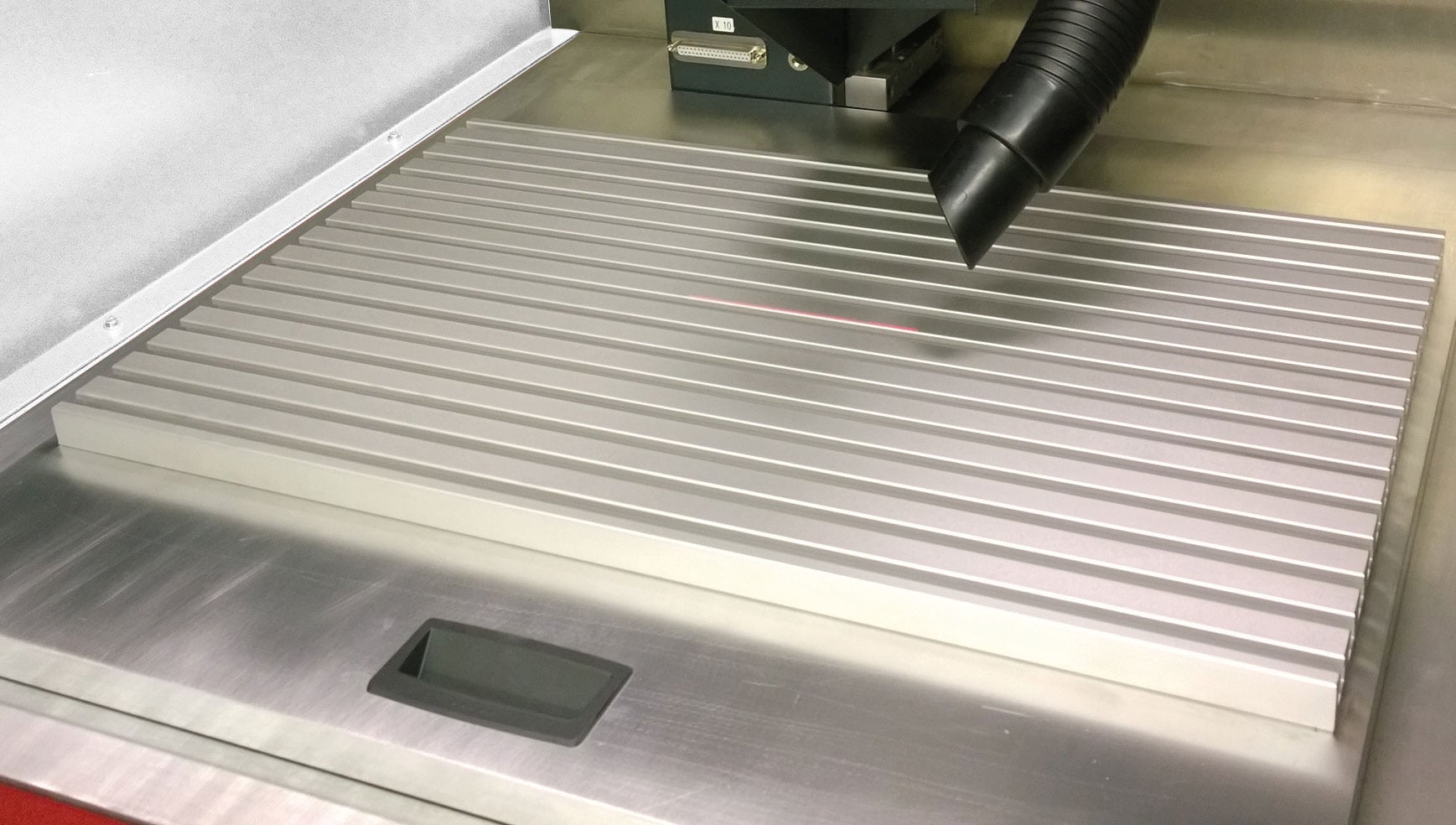

Table recording with T-slots

The support plate with T-slots is ideal for recording customer-specific workpieces or clamping fixtures.

Special roles

Machines with base frames or laser workstations can be equipped with Rollfüßen and can therefore be used on flat floors mobile.

The wheels have a special construction, which ensures the continuous load of the machine weight and a secure stand.

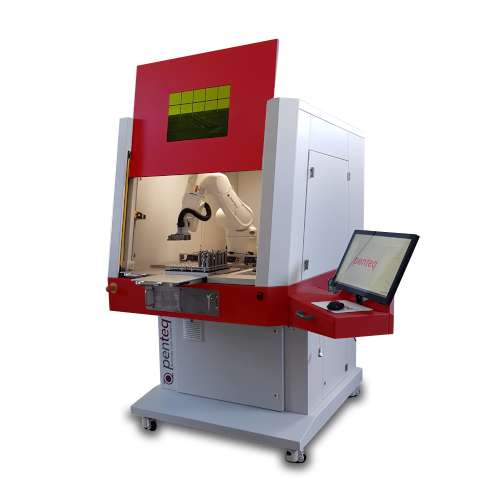

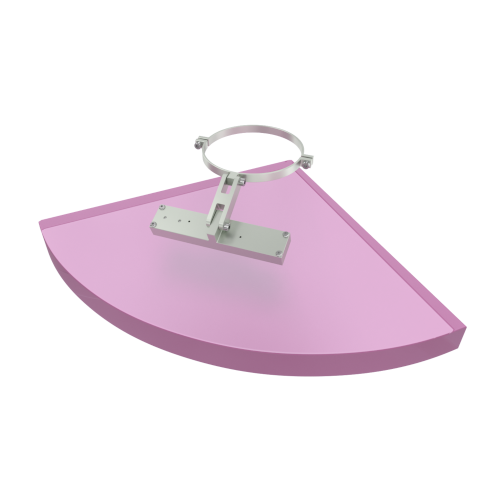

Control Panel on swivel arm

Ideal for achieving a fatigue-free, ergonomic working position, regardless of the size of the plant operator.

The massive swivel arm can be adjusted in height and angle of inclination.

Furthermore, the swivel arm has a support surface for the keyboard and mouse and allows an ordered cable guide.

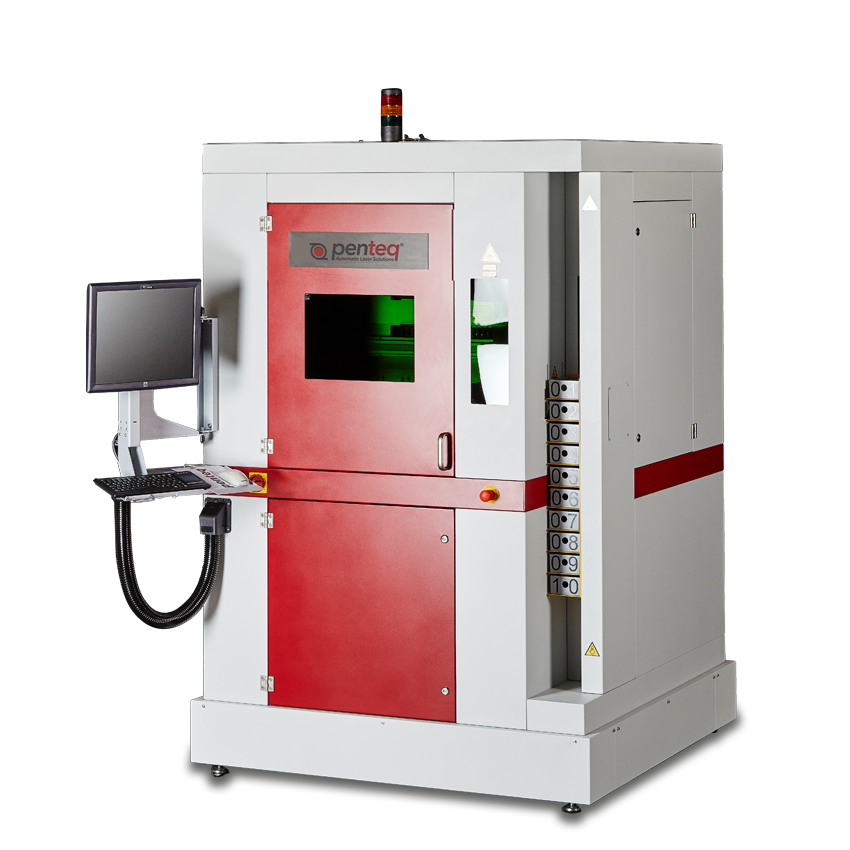

Signal lamp

The signal lamp serves as a widely visible sign for information about the current state of the system.

The high-quality industrial luminaire has a smooth surface and is resistant to contamination and easy to clean.

By contrasting colours with high luminous force, the displayed state is immediately recognizable from all sides.

Foot

To trigger the machining operation with the foot in place of the Start button of the control, the freely positioned footswitch is used.

The robust design made of die-cast aluminium is designed for long-term use in industrial environments.

Handheld scanners

Barcode scanner for printed codes

The laser handheld scanner is a smart sensor for automatic and non-contact detection and decoding of barcodes. Capturing of all common 1d barcodes even from extreme angles makes the work easier. No need to align scanners or barcodes to achieve higher throughput times.

The scanner can be used flexibly in manual or free-hand operation. Bluetooth allows for great freedom of movement without an annoying cable.

Poor lighting conditions or sunlight do not cause any problems.

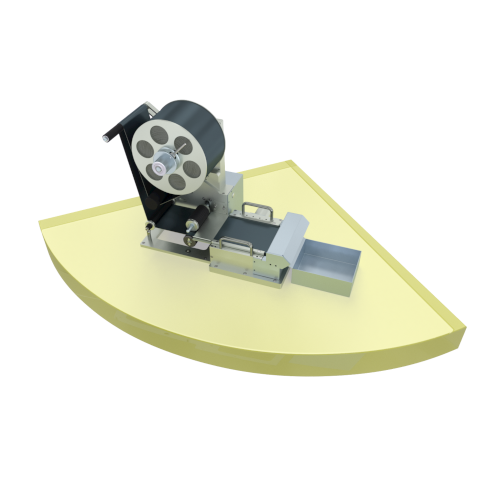

Positioning laser

The positioning laser or preview laser projects a preview of the desired selection or a frame over the outer contour for object orientation.

This means that workpieces without stops or workpieces can be manually positioned in the laser cell.

The red light laser used is harmless and offers a good contrast on most materials.

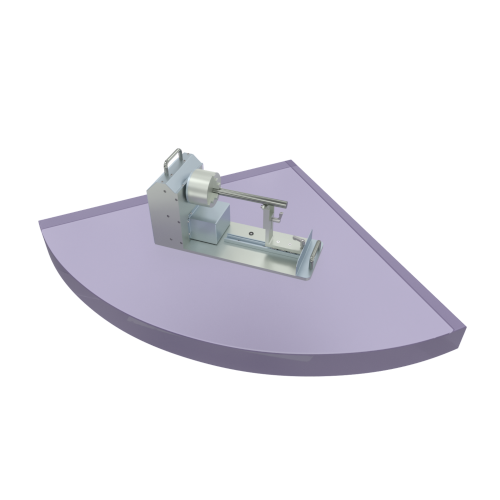

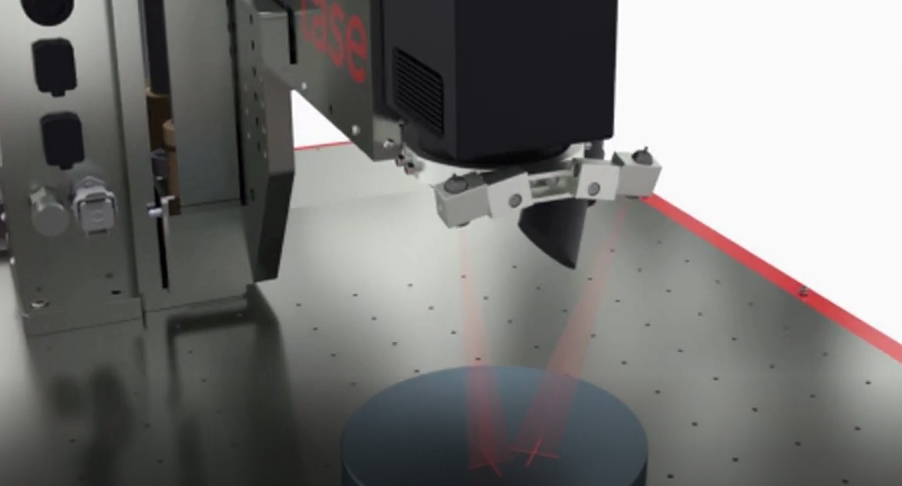

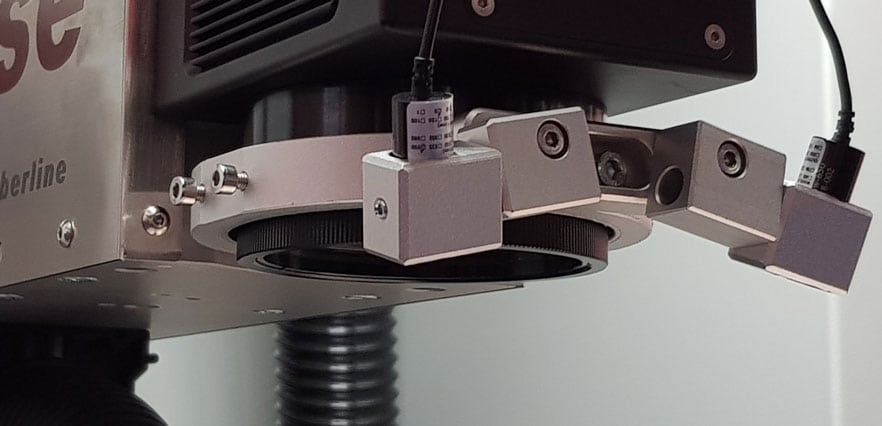

Focus Finder

Allows easy locating of the correct focus distance to the material surface at unknown workpiece height without measuring.

If the two red light laser projections overlap, the distance is set.

Vision Check and confirm

If a standard-compliant test according to AIM-DPM or ISO/IEC TR 29158 is not desired, reading the codes and checking with the data on order is a quick and inexpensive option.

This variant is especially considered when the test is used for internal quality control.

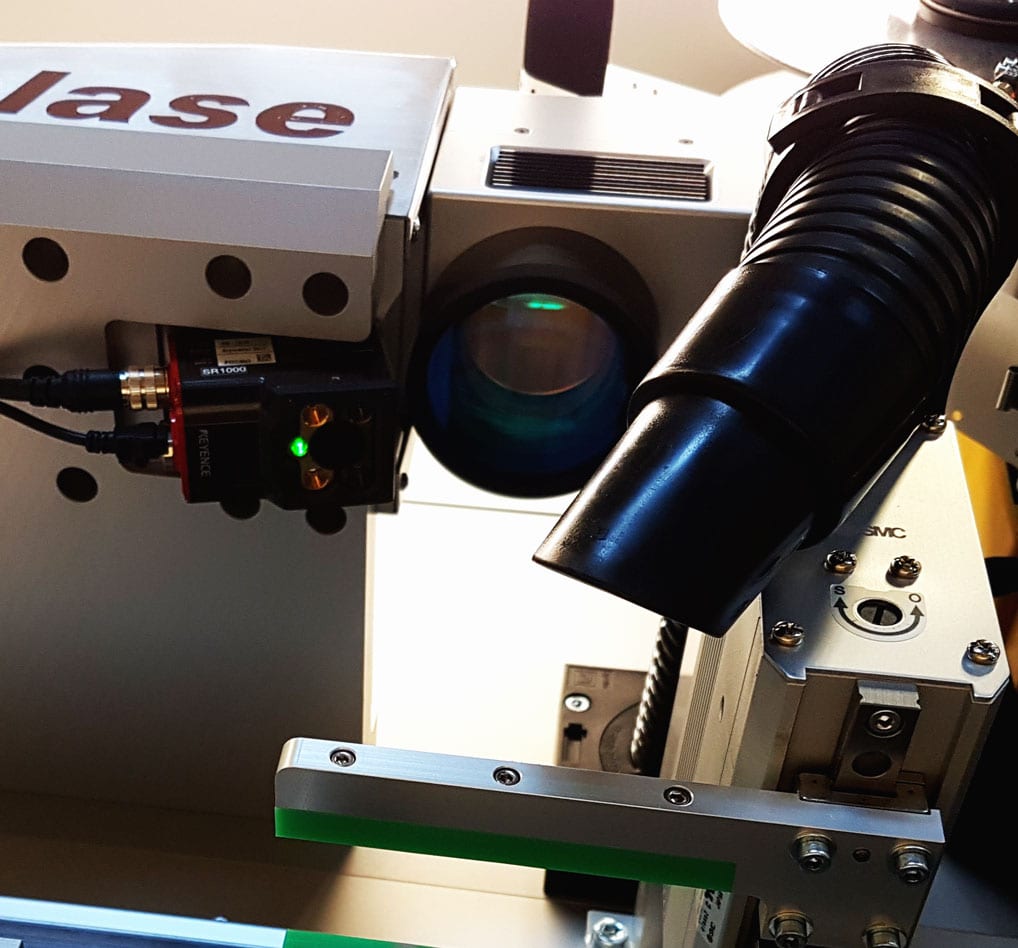

Vision-verifier-DMC Camera

verifying e.g.: Data matrix codes ECC 200 according to quality A-f according to ISO/IEC TR 29158 (AIM-DPM)

After the labeling process, an automatic check and output of the quality level is performed upon activation, which can also be saved as a log if desired.

This allows the user to document the audit to his customer.

The test can be activated individually or selected in series production as a continuous inspection for each label or as a sample test in a freely adjustable cycle (e.g.: every 50 label).

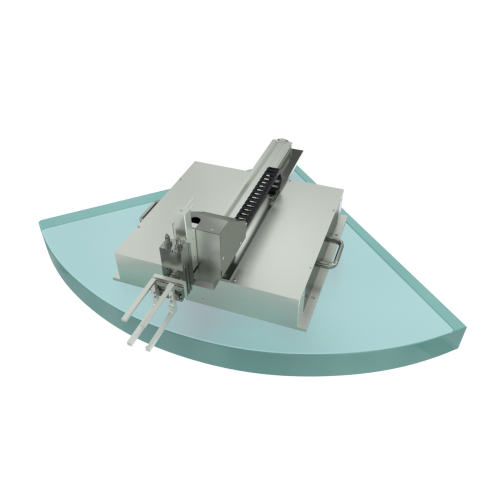

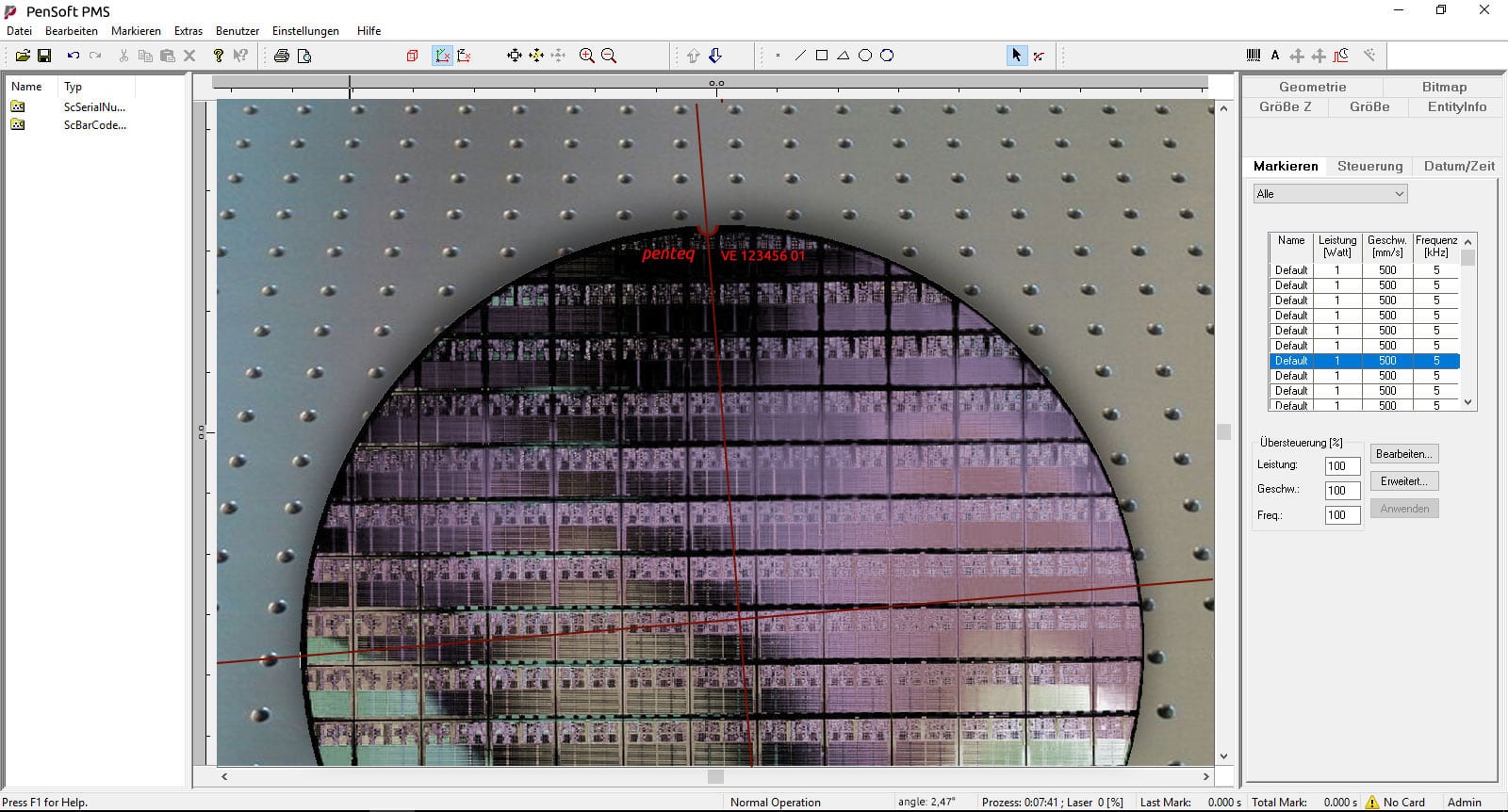

Penteq Smart Adjust (PSA)

Penteq Smart Adjust enables precise positioning of the label layout, even on small workpieces.

A camera displays the live image of a workpiece to be labeled directly in the transparent layout of the PenSoft editor interface.