Laser process

Overview of the different procedures

The different laser methods can be used individually or in combination. In our extensively equipped laser laboratory, we determine the most suitable method for your application according to your specifications. All beam sources relevant for laser material processing are available in various power classes and wavelengths.

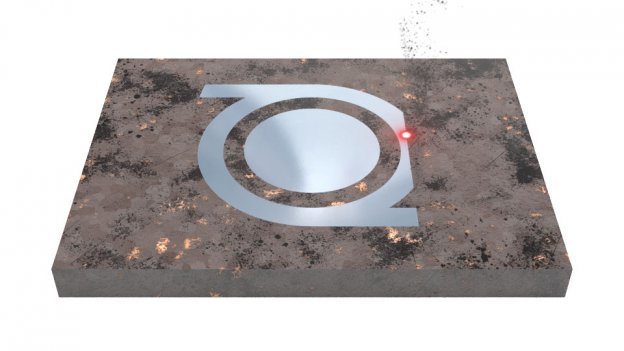

Laser cleaning

Vaporisation is used to remove superficial layers of topcoat or dirt in a resource-saving manner.

Particularly environmentally friendly due to the complete absence of cleaning agents or chemicals. This process also enables the selective cleaning of partial surfaces or the exposure of contact surfaces. The configuration of the laser system depends on the material and type of soiling as well as the permissible degree of influence on the material surface to be processed.

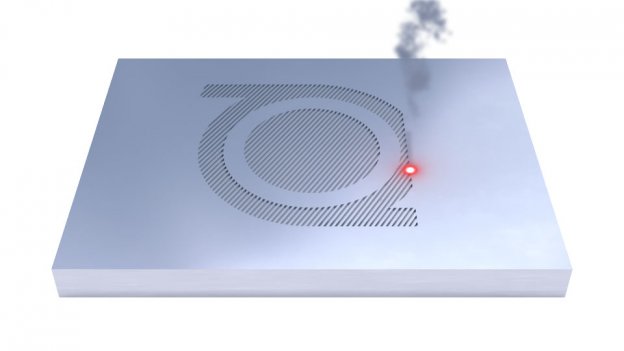

Laser structuring

Laser surface treatment is a rapidly growing field and makes it possible, for example, to produce tribologically optimised surfaces. The desired result can be an increase in friction or, on the contrary, a reduction to minimise friction or wear. The process can also be used to prepare bonding points and provides the best conditions for subsequent bonding processes.

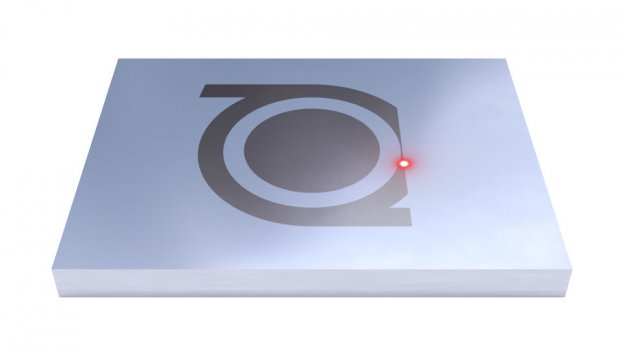

Occasion labelling

Can be used on all metallic materials that cause a change in colour due to the thermal effect. Controlled oxidation produces a permanent, coloured marking from dark grey to anthracite, which is largely gentle on the material. Particularly suitable for most steels where smooth, unaltered surfaces are crucial.

With certain materials (e.g. stainless steel), different tempering colours can be achieved by modifying the blasting properties.

Ultra Black Marking

Ultra Black Marking is an advanced marking process that uses the Signolux ultrashort pulse laser (USP) to create extremely high-contrast, deep black markings on metallic surfaces. The special feature of this process is the extremely short pulse duration (in the range of <10-¹² s), which enables ablation-free, cold processing. This results in no burrs, no melting edges and no material changes in depth. Ultra Black Marking creates defined nanostructures (Laser Induced Periodic Surface Structures, LIPSS) on the metal surface, which absorb the light diffusely and independently of the angle. Particularly suitable for the highest requirements in terms of durability, legibility and biocompatibility, as required in medical technology (UDI codes), for high-quality stainless steel components or in the aerospace industry.

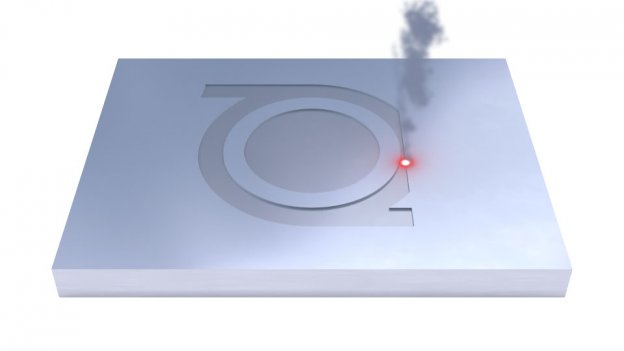

Laser engraving

Laser engraving is a subtractive process in which a permanent indentation is created in the surface of a workpiece through targeted material ablation with a focussed laser beam. The laser beam acts locally on the material with high power density, vaporising it. The result is a tactile engraving that is permanent, abrasion-resistant and weatherproof. The engraving depth can be precisely controlled by parameters such as laser power, pulse frequency, feed rate and number of passes. Laser engraving is suitable for functional markings (e.g. serial numbers, scales), decorative applications and for micro-engraving on the smallest components, for example in the electronics or watchmaking industry.

Plastic labelling

A wide range of different plastics can be labelled using colour change.

Carbonising is used for light-coloured plastics, while foaming is suitable for dark-coloured plastics. Foaming creates tiny air bubbles in the material structure which then appear light in colour.

By adding additives during the manufacture of plastic products, the material properties can be optimised for laser processing. Many plastics can also be labelled with the best results using special laser beam sources.

Additive labelling (LaseColour)

Additive laser marking is a process for labelling materials in which a coating material is applied to the surface using a laser. In contrast to ablative labelling, no material is removed but an additional layer is created. This process is particularly suitable for dark, high-contrast markings on light-coloured materials such as plastics or metals and offers high resistance to abrasion, chemicals and weathering. Requires precise coordination and determination of the ideal material pairing.

Ablation labelling

If materials are coated or painted with a top layer, this layer can be removed and vaporised by the laser. The layer underneath is revealed. This makes it possible to produce different colour combinations and markings with high contrast. Applications include the day/night marking of black painted plastic parts or the vaporisation of the anodised layer of aluminium.

Laser fineblanking

Laser fine cutting with galvo lasers, also known as remote cutting, is a high-precision, non-contact cutting process in which the laser beam is directed extremely quickly and precisely onto the workpiece via a galvanometer system (mirror scanner). This process makes it possible to cut the finest contours in thin materials - such as metals, foils or plastics - at high speed and with minimal thermal impact. The flexible beam guidance makes remote cutting particularly suitable for automated processes in electronics, medical or microsystems technology.

Laser welding

The laser welding process is characterised by low thermal distortion and high welding speeds combined with high precision. Innovative scanner welding with the DPW process enables dynamic seam tracking thanks to an integrated vision system and is suitable for the precise welding of metals. Laser transmission welding of plastics (thermoplastics) offers major advantages over other processes. The part of the workpiece facing the laser is laser-transparent and the part underneath is absorbent. The absorbent part is melted and welded to the transparent part.

Laser drilling

Lasers can be used to drill holes in a wide variety of materials with high precision and without wear. The material is melted and vaporised and driven out of the drill hole by the resulting pressure. Trepanning or trepanning drilling is an established process. In a first step, a starting hole is created, which is then expanded to the desired size in a circular pattern by making several passes. Other methods include single-pulse drilling and percussion drilling with rapid successive pulses.

Laser stripping

Stripping wires or cables with a laser is a reliable method of creating a clean contact surface. Depending on the size and diameter of the cables or wires, 2, 3 or 4 laser heads are used. The insulating material is vaporised segment by segment and removed by a powerful extraction system. The process is ideal for stripping enamelled copper wires and can be easily automated.

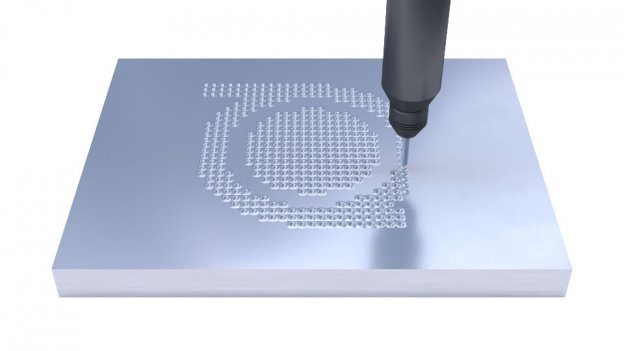

Alternative process - needle embossing

A pneumatically or electrically driven metal pin permanently marks a dot matrix or linear character into the material surface - logos or data matrix codes can also be marked in addition to plain text. Surface irregularities of up to 5 mm can be easily levelled out. Metal components are permanently and quickly labelled and can be read even after further processing. The embossers can be used cost-effectively in a wide range of stand-alone and online applications.