Penteq Laser

About our company

As a highly specialised team, we develop and produce integration lasers,

automatic laser systems and laser workstations including vision and software

OUR UNIQUENESS - A CONSISTENT SYSTEM:

Modular thought and modular made

The term modular design is often used in mechanical engineering, but such a consistent approach is unique. Modularity must be seen as the basis for every development right from the start.

This way of thinking led to our FunctionsModule-LaserSystem, which took a lot of effort to realise, but it was worth, a thousand times over!

This enables us to create customised solutions with tried-and-tested modules manufactured in series that fully cover the requirements.

From the first step to the finished machine - the building blocks

Laser expertise

A project usually starts with an application with individual requirements. Our extensively equipped laser laboratory offers the best conditions for achieving the desired result.

In addition to our fibre lasers and CO² lasers in various power classes, UV lasers and ultrashort pulse lasers are also available. These can also be configured specifically for the application. Beam-shaping optical components such as beam splitters, beam expanders or diffractive optics offer many possibilities.

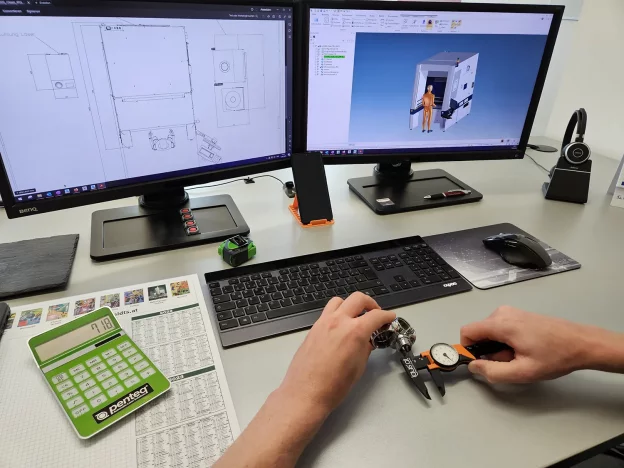

Construction

Using 3D CAD software specially developed for high-tech mechanical engineering, our experienced designers develop lasers, machine and system solutions as well as devices and fixtures. The creation of a "digital twin" enables us to recognise and avoid potential problems as early as the design phase.

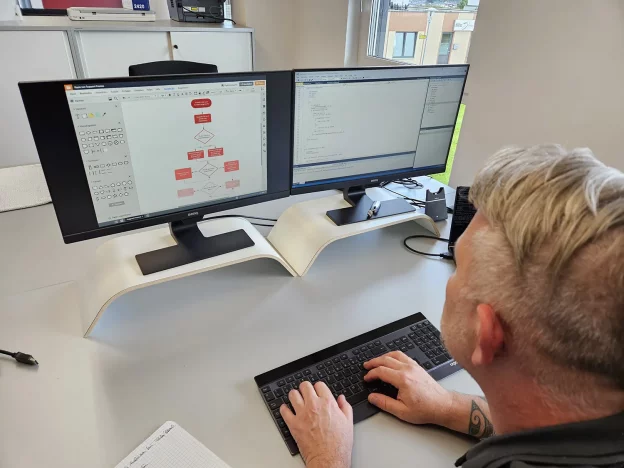

High-level languages software development and programming

In order to optimise the implementation of customer-specific processes, we have also transferred modularity to our software. With the Penteq framework, connections to database or ERP systems can be made via tried and tested interfaces.

Smart Factory and a networked factory are realised through the implementation of our software, which creates the connection to your product. We digitally upgrade our customers' production to Industry 4.0. Large industrial companies in particular rely on our expertise and value our short communication channels.

Integrated vision systems

Today, vision systems are an integral part of modern laser machines and play a decisive role in precision, process reliability and automation. AI-supported software is increasingly making them even smarter and more flexible in terms of their possible applications. Thanks to the combination of high-resolution camera technology, intelligent image processing and real-time data analysis, they enable adaptive control of laser processes - especially in applications with high component variance, tight tolerances or automated production lines.

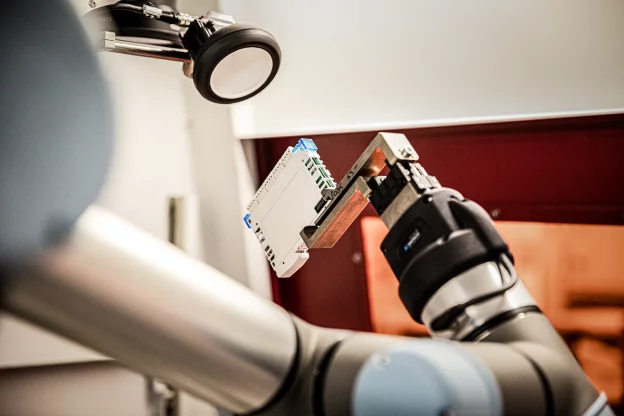

Automation technology + robotics

Our approach is to create efficient production systems and utilise automation where it makes sense to do so.

Robots perform precise handling tasks, position complex components or guide the laser system along defined processing paths. Automatic loading and unloading, integrated sensors and adaptive path planning minimise set-up times and ensure consistent quality at high cycle rates. Combined with vision systems and intelligent control, flexible, scalable production cells are created for industrial series production.

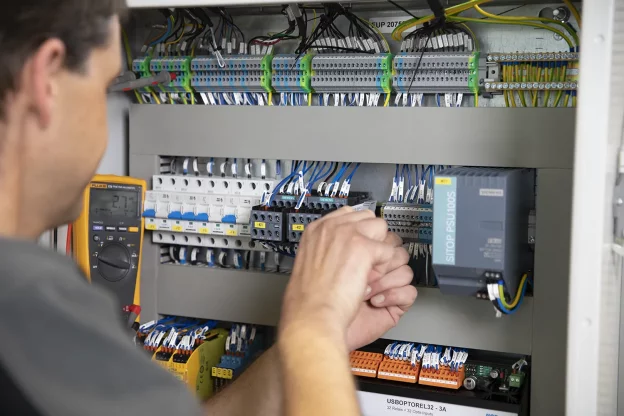

Electrical design and switch cabinet construction

Modern electrical engineering is intelligent and, in combination with innovative automation technology and software, opens up almost unlimited possibilities. Seamless integration of ECAD systems allows electrical components to be planned consistently, cable routes to be checked in the model and errors to be recognised at an early stage. Automated circuit diagram creation and modular function blocks speed up the design process - especially with frequent variants and customised adaptations.

Production and assembly

We manufacture our OEM lasers, high-tech machines and turnkey systems using high-quality materials and components

A robust industrial design (SID), highly dynamic drives and an innovative control concept with integrated soft PLC are the ingredients for systems and installations from a single mould.

Research and development (R&D)

Interdisciplinary innovation, digital methods and the strategic further development of technologies take centre stage. Our modern R&D acts as a driver for efficiency, sustainability and new business models.

The AI-supported design of complex systems and the interlinking of mechanics, sensors and software for autonomous or adaptive control machines ensure a competitive advantage. Close collaboration with universities, institutes and start-ups ensures that research is quickly translated into marketable products.

Our vision

What sets us apart

Specialising in the development and production of innovative systems and equipment in the field of industrial laser material processing, Penteq is today one of the leading companies in Austria.

Innovative concepts combining laser expertise, image processing and automation technology, as well as our own software development, enable us to offer our customers end-to-end solutions.

The great commitment, expertise and constant willingness of our employees to develop further form the foundation for sustainable company growth.

Laser cleaning systems protect the environment.

Product labelling for traceability and protection against counterfeiting is becoming increasingly important and has become indispensable for quality-conscious companies.

The aim is to promote the application safety and environmental compatibility of the products and to protect responsible companies from plagiarism from inferior, environmentally harmful and therefore cheaper production in the short term.

Our aim is to ensure that the labelled and identified product can be specifically fed into a recycling process and reused.

From trading company

to producer

Penteq can look back on a long company history that began in 1968.

The first customised solutions were developed.

Paul Penkner's son Thomas Penkner takes over the company at the age of 19. The company specialises in trading in tools and machines for metalworking.

Paul Penkner left the company and founded his own company in 1170 Vienna, Elterleinplatz, which also specialised in the sale of machine tools.

Paul Penkner senior founds the company Penkner-Meissner OHG with Mr Wilhelm Meissner in the 17th district, Kastnergasse 21.

Kastnergasse soon served as a warehouse, while the sales and office moved to the 18th district, Kreuzgasse 44-46. The company focussed on the import and sale of tools and machines for metalworking.