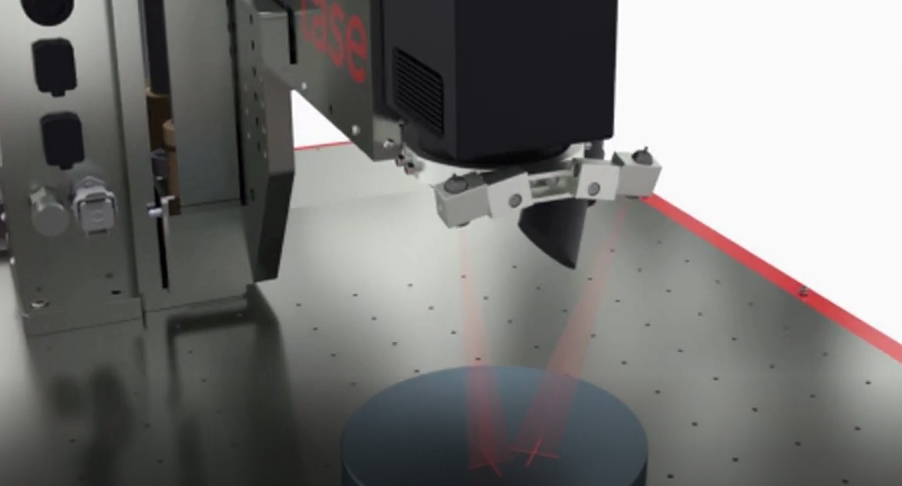

Laser processes

Nachfolgend zeigen wir eine Übersicht der verschiedenen Verfahren

These can be used individually or also in combination.

In unserem Laserlabor ermitteln wir nach den Vorgaben unserer Kunden die am besten geeignete Methode.

Event label

Applies to all metals, which causes a change in colour due to the thermal effect.

Neither a discharge nor a removal of the material allows the marking of already processed surfaces.

For certain materials (example stainless steel) different colors can be represented by modification of the beam properties.

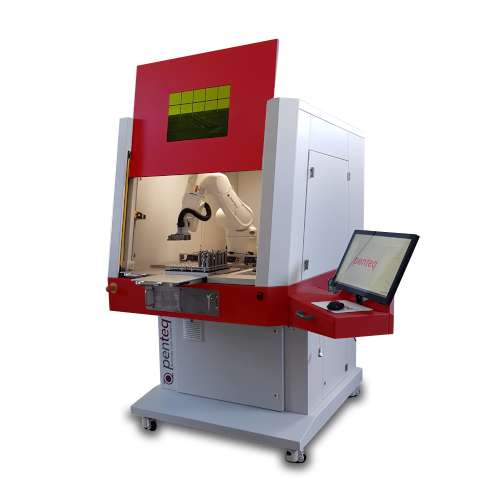

Damit ist es oft einfacher und sinnvoller andere Bearbeitungsarten (Einpressen, Fügen, Bohren, Stanzen etc.) und Prozesse wie beispielweise das Prüfen von Bauteilen (Kameraprüfung, Messen, Wiegen, Gegenprüfen) in der Laseranlage durchzuführen.

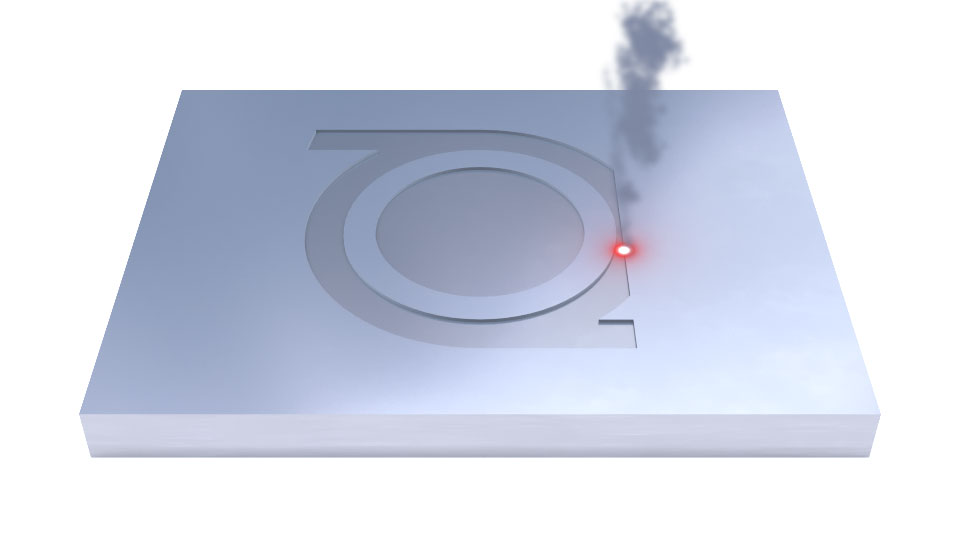

Engraving/Depth Labeling

Evaporation or melting of the material results in a material removal in a narrowly limited area.

In addition to metals, these methods can also be applied to plastics and other materials.

It is characterized by durability against abrasion and corrosion and can be used in addition to marking for the production of embossing tools or clichés.

Plastic marking

A wide variety of different plastics can be labelled by means of a colour cover.

Carbonisation is applied in light plastics, while foaming is suitable for dark plastics.

By adding additives to the production of the plastic products, the material properties for laser processing can be optimized. Many plastics can also be labeled with the best results by using special laser beam sources.

Additive label (LaseColour)

Procedure for order and merge additional material onto a carrier material.

Offers high contrast and great variance in color and material selection.

is used in materials which are not processed with the usual procedures or where the desired results cannot be achieved.

Requires precise coordination and determination of the ideal material pairing.

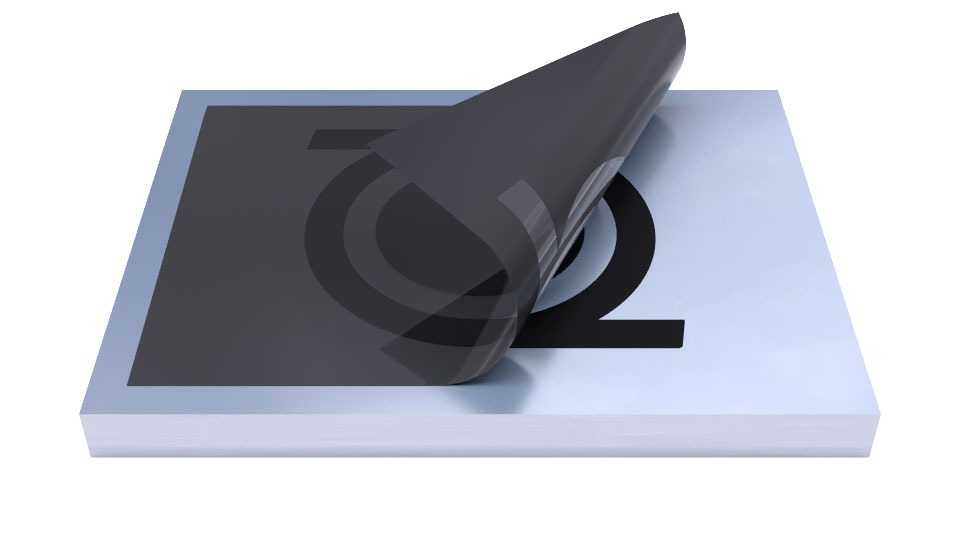

Abtragsbeschriftung

If materials are coated or painted with a covering layer, this layer can be removed and evaporated by the laser.

The underlying layer appears. This makes it possible to create different color combinations and markings with high contrast.

Applications are the day/night marking of black lacquered plastic parts or the evaporation of the anodic coating of aluminium.

Laser cleaning

By evaporation, surface layers of cover or dirt are removed from the resource sparingly.

Especially environmentally friendly due to complete elimination of detergents or chemicals.

This method also allows selective cleaning of subsurfaces or the unloading of contact surfaces.

Depending on the material and type of contamination as well as the permissible degree of influence of the material surface to be processed, the laser system is configured.

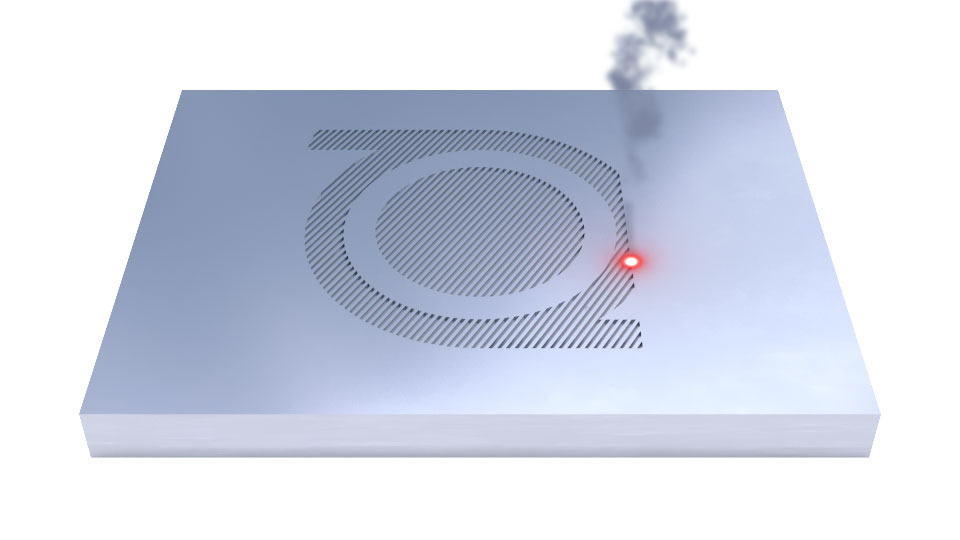

Laser structuring

Laser surface treatment is a rapidly growing area and allows, for example, tribologically to produce optimally designed surfaces. An increase in friction or, on the contrary, a reduction in friction or wear reduction can be the desired result. The process can also be used for gluing preparation and provides the best conditions for subsequent adhesive processes.

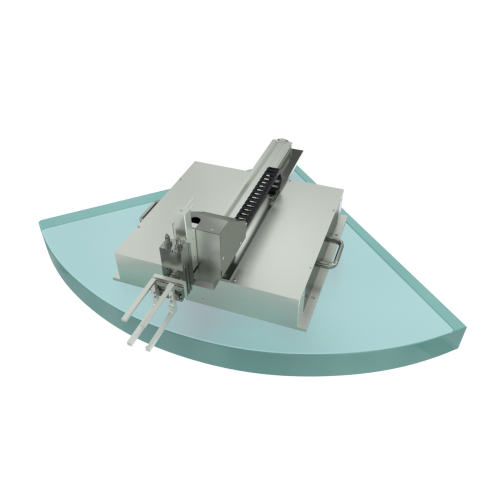

Laser Fine Cutting

The laser fine-cutting process is also suitable for complicated contours and high accuracies.

The cut edges have a small ridge and little roughness. Laser cutting is the optimal solution for a multitude of different materials and material composites.

Thanks to the fast laser movement, the thermal influence zone is reduced and sensitive materials can also be precisely separated.

Compared to mechanical processes such as punching, the advantage is the failure of a tool.

Laser welding

The laser welding process is characterized by low thermal distortion and high welding speeds while maintaining high precision. The Laserdurchlichtschweißen of plastics (thermoplastics) offers great advantages over other processes. The workpiece part facing the laser is laser-transparent and the underlying part absorbs. By melting the absorbent part, the welding is done with the transparent part.

Laserbohren

Mittels Laser können Bohrungen in verschiedenste Materialien in hoher Präzision verschleißfrei hergestellt werden. Dabei wird das Material aufgeschmolzen und verdampft und durch den dabei entstehenden Druck aus dem Bohrloch getrieben. Ein etabliertes Verfahren ist das Trepanieren oder Trepanierbohren. In einem ersten Schritt entsteht ein Startloch, welches anschließend kreisförmig durch mehrere Überfahrten auf die gewünschte Größe ausgeweitet wird. Weitere Verfahren sind das Bohren mit Einzelpuls sowie das Perkussionsbohren mit schnell aufeinanderfolgenden Pulsen.

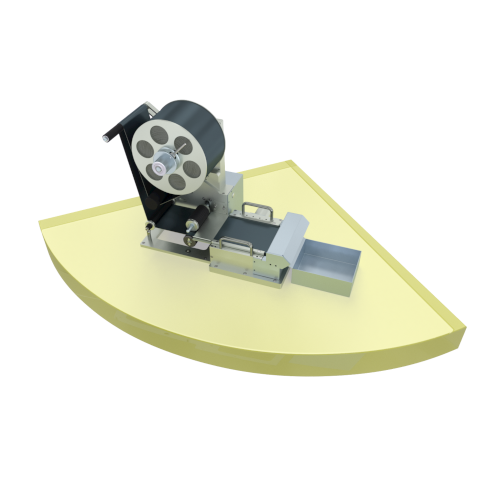

Laser stripping

Abisolieren von Drähten oder Leitungen durch den Laser ist eine zuverlässige Methode um eine saubere Kontaktfläche herzustellen. Je nach Größe und Durchmesser der Leitungen oder Drähte werden 2, 3 oder 4 Laserköpfe eingesetzt. Das Isoliermaterial wird segmentweise verdampft und durch eine leistungsfährige Absaugung abgeführt.

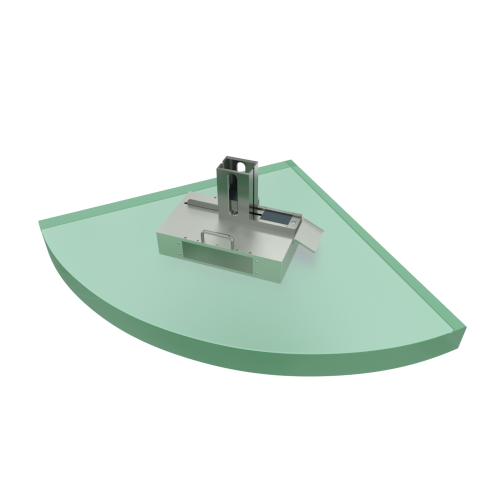

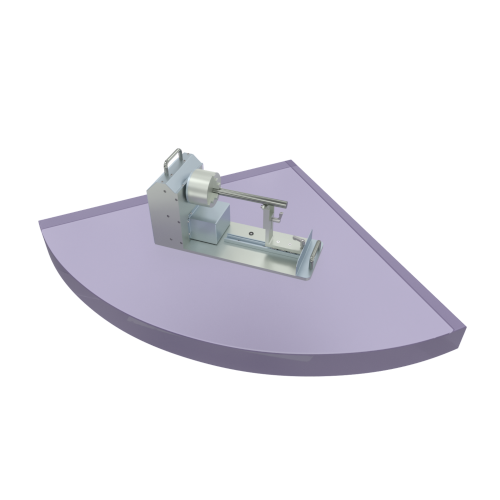

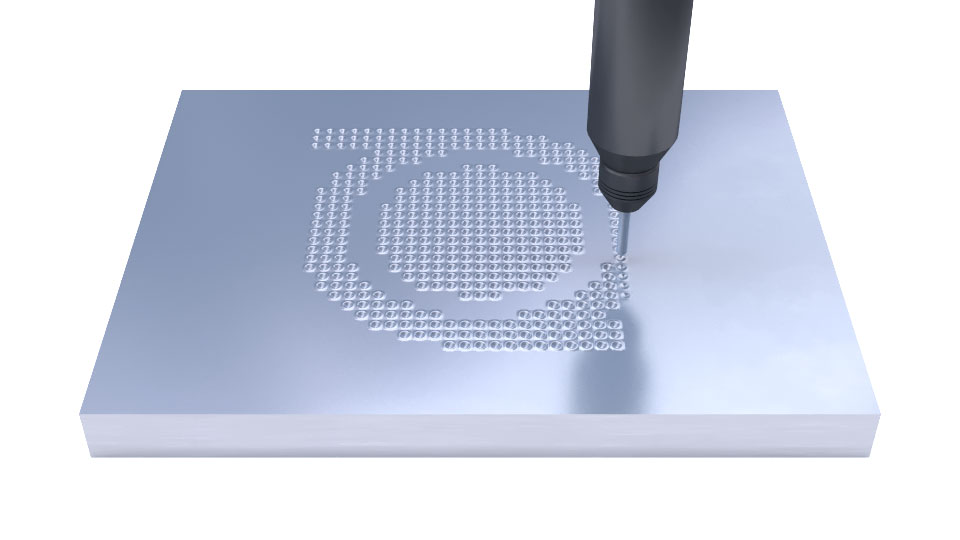

Alternative procedure – Embossing of the needle

A pneumatic or electrically driven metal pin permanently strikes a dot matrix or line-shaped character in the material surface – in addition to a clear font, logos or data matrix codes can also be marked. Unevenness of the surface can be easily compensated up to 5mm. The identification of metallic components rfolgt permanently and quickly and can also be read after further treatment. The stamping machine can be used cost effectively in a wide range of stand-alone and online applications.