Tool and mould making

Laser marking for labelling or functional engraving

Laser marking in tool and mould making

Whether laser marking for labelling or functional engraving - our flexible laser systems can do both.

In modern tool and mould making, maximum precision, repeat accuracy and surface quality are essential. This is precisely where laser technology sets new standards. Whether for removing release agents and oxide layers, preparing mould surfaces to give structure, micro-marking or precise repair welding - lasers have become indispensable in tool and mould making. Non-contact processing minimises thermal stress, reduces tool wear and enables the highest level of detail accuracy, even with complex geometries or sensitive surfaces. At the same time, laser-based processes are fast, reproducible and easy to automate - ideal for modern series and one-off manufacturers. With our modular laser systems, PENTEQ offers customised solutions for daily practice in toolmaking, mould making and plastics technology. Whether as a standard system or a customised integrated system, our lasers work where precision is crucial - reliably, economically and future-proof.

Precision that lasts - durable, forgery-proof, suitable for industrial use

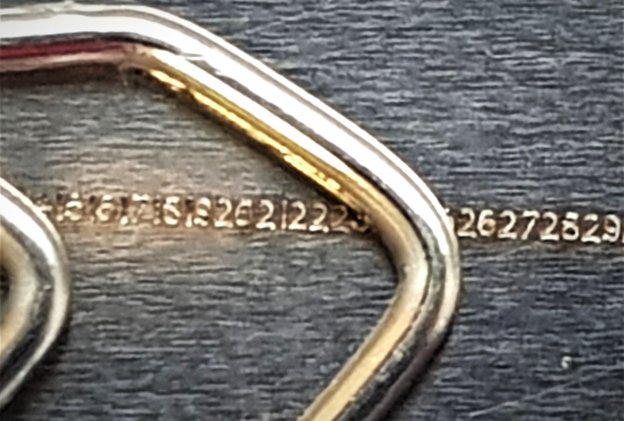

In modern tool and mould making, permanent and precise marking of components is essential. Whether serial numbers, logos, material labelling or DMC or QR codes, laser marking offers an efficient, wear-free and high-resolution solution - directly on metals and engineering plastics.

Damage-free & high-precision

One of the main advantages of laser marking is that it is a non-contact process, meaning there is no physical contact between the laser and the material to be marked. This also makes it suitable for marking sensitive materials and eliminates the risk of damaging the material.

Another advantage of laser marking is that it produces highly precise and accurate markings that are not possible with conventional marking methods. The laser beam can produce markings with small character sizes and high-resolution graphics, making it ideal for applications that require intricate markings or codes.

Applications in mould and tool making:

Engravings on mould inserts, tool cores or electrodes

Type plates and mould numbers

Labelling of interchangeable plates

Standard parts and devices

Micro labelling for miniaturised mould elements

Standard parts and devices

Micro labelling for miniaturised mould elements

QR or DataMatrix codes for digital tool management

The advantages of laser marking in tool and mould making

Flexible and economical

- Flexible layout design: Labelling with logos, plain text and serial numbers and codes

- Customised: Batch codes, CAD data,

QR codes, etc. - Suitable for end-to-end product traceability

- Shape engraving, for example for embossing stamps

- 3D contour engraving

Forgery-proof

- Tampering leaves visible traces

- Clearly identifiable through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high readability

- Can be labelled quickly: by engraving or colour change

Resistant

- Highly resistant to heat, abrasion and chemicals

- Controllable penetration depth for engravings