Tool and mould making

Laser marking for labelling or functional engraving

Laser marking in tool and mould making

Whether laser marking for labelling or functional engraving - our flexible laser systems can do both.

In modern tool and mould making, maximum precision, repeat accuracy and surface quality are essential. This is precisely where laser technology sets new standards. Whether for removing release agents and oxide layers, preparing mould surfaces to give structure, micro-marking or precise repair welding - lasers have become indispensable in tool and mould making. Non-contact processing minimises thermal stress, reduces tool wear and enables the highest level of detail accuracy, even with complex geometries or sensitive surfaces. At the same time, laser-based processes are fast, reproducible and easy to automate - ideal for modern series and one-off manufacturers. With our modular laser systems, PENTEQ offers customised solutions for daily practice in toolmaking, mould making and plastics technology. Whether as a standard system or a customised integrated system, our lasers work where precision is crucial - reliably, economically and future-proof.

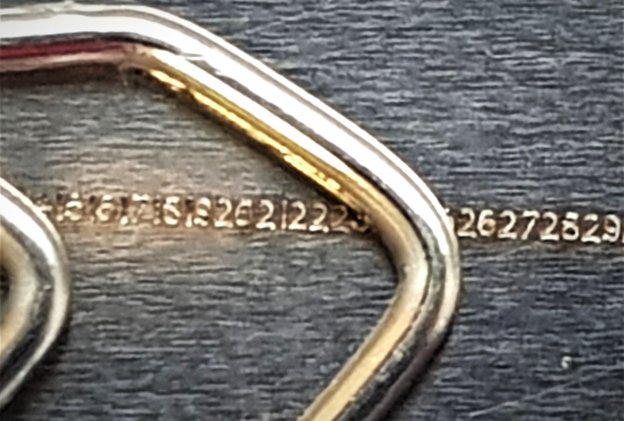

Precision that lasts - durable, forgery-proof, suitable for industrial use

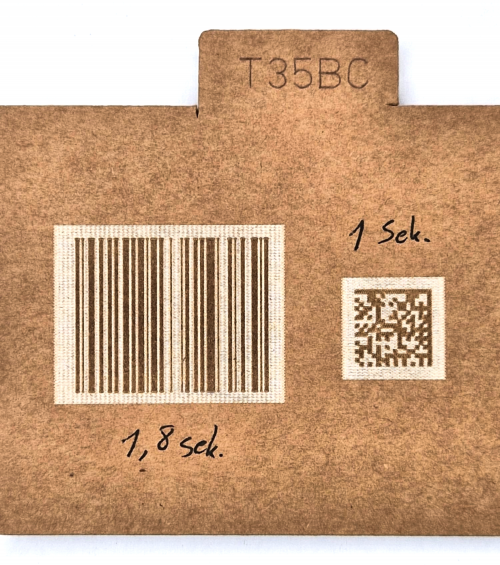

In modern tool and mould making, permanent and precise marking of components is essential. Whether serial numbers, logos, material labelling or DMC or QR codes, laser marking offers an efficient, wear-free and high-resolution solution - directly on metals and engineering plastics.

Damage-free & high-precision

One of the main advantages of laser marking is that it is a non-contact process, meaning there is no physical contact between the laser and the material to be marked. This also makes it suitable for marking sensitive materials and eliminates the risk of damaging the material.

Another advantage of laser marking is that it produces highly precise and accurate markings that are not possible with conventional marking methods. The laser beam can produce markings with small character sizes and high-resolution graphics, making it ideal for applications that require intricate markings or codes.

Applications in mould and tool making:

Engravings on mould inserts, tool cores or electrodes

Type plates and mould numbers

Labelling of interchangeable plates

Standard parts and devices

Micro labelling for miniaturised mould elements

Standard parts and devices

Micro labelling for miniaturised mould elements

QR or DataMatrix codes for digital tool management

The advantages of laser marking in tool and mould making

Flexible and economical

- Flexible layout design: Labelling with logos, plain text and serial numbers and codes

- Customised: Batch codes, CAD data,

QR codes, etc. - Suitable for end-to-end product traceability

- Shape engraving, for example for embossing stamps

- 3D contour engraving

Forgery-proof

- Tampering leaves visible traces

- Clearly identifiable through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high readability

- Can be labelled quickly: by engraving or colour change

Resistant

- Highly resistant to heat, abrasion and chemicals

- Controllable penetration depth for engravings

Suitable products

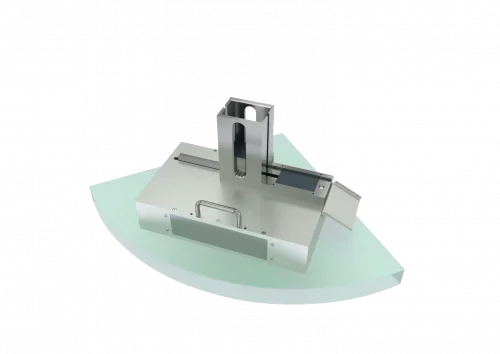

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

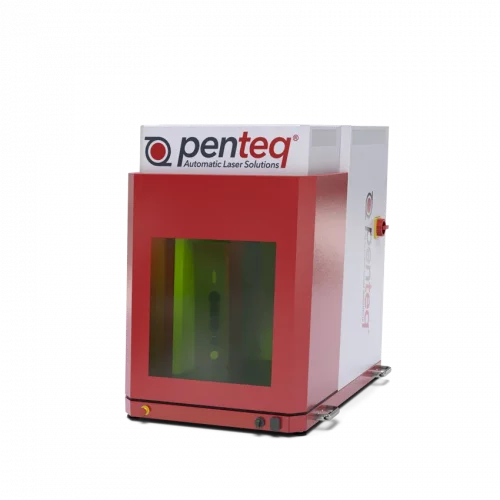

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

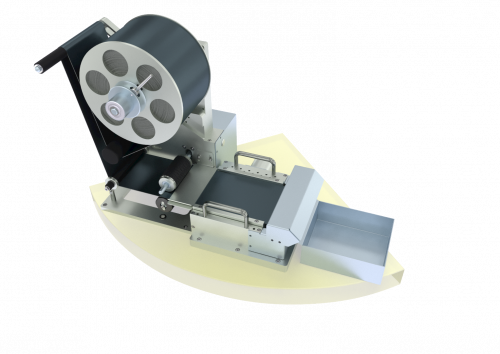

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

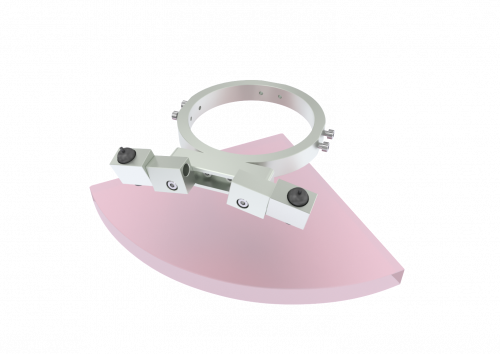

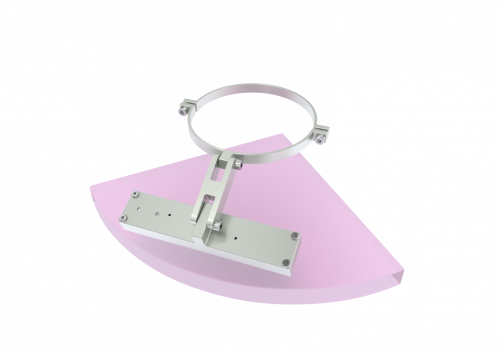

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust