Laser labelling in the packaging industry

Permanent labelling for products & processes

Laser labelling for packaging - precise & permanent

Permanent labelling for products & processes

Penteq offers the optimum laser technology for almost any material to mark packaging quickly and in high quality

Laser labelling of packaging - durable, precise & environmentally friendly

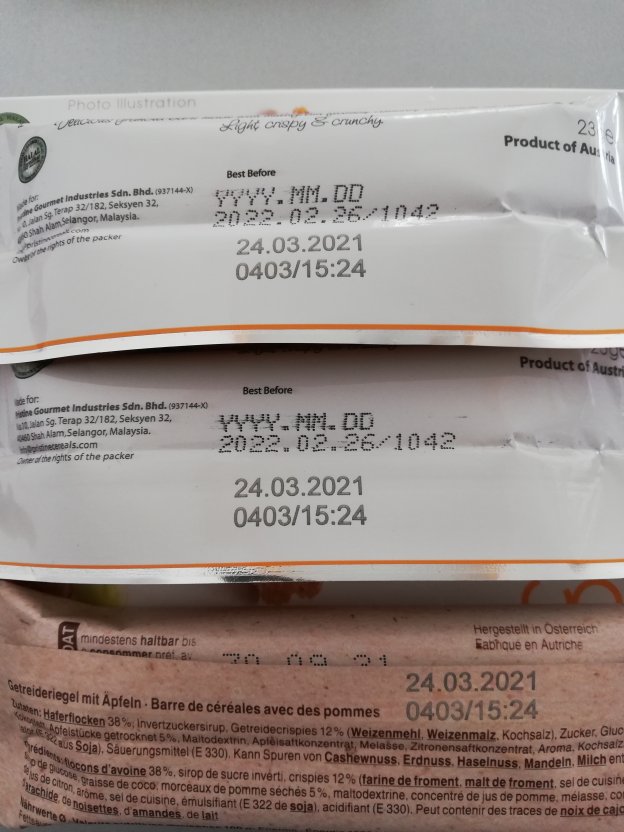

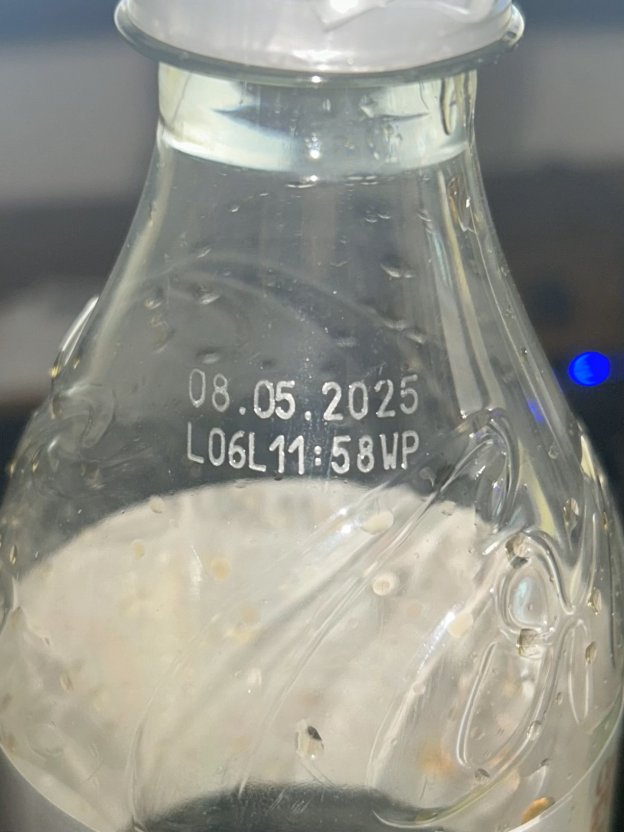

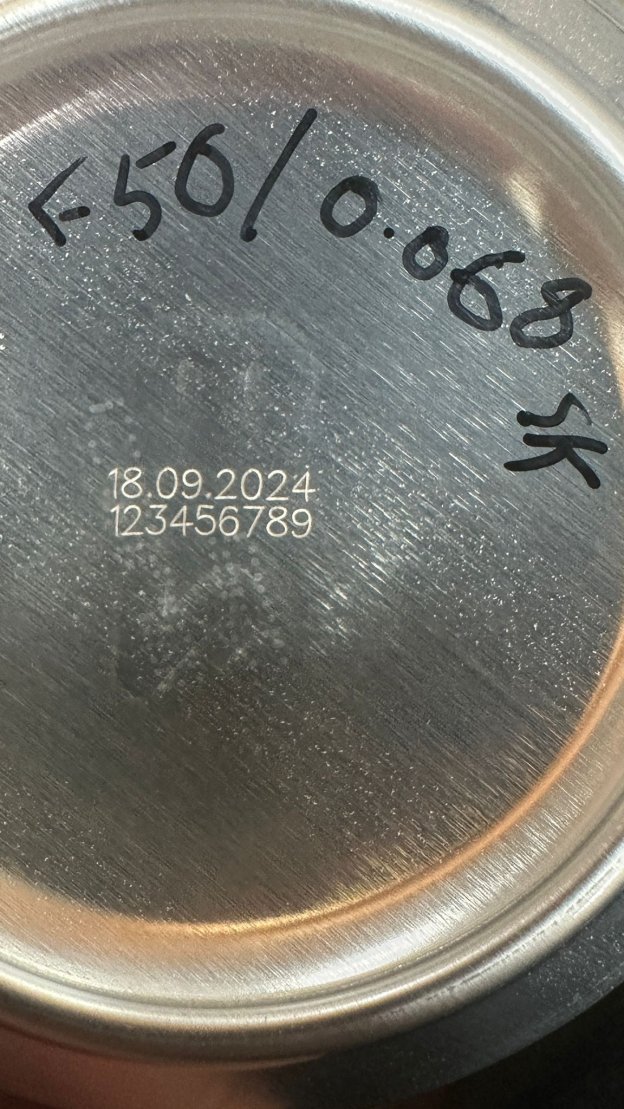

Precise, legible and reliable labelling is essential in the packaging industry - be it for best-before dates, batch numbers, barcodes or brand logos.

Laser labelling offers an economical, environmentally friendly and particularly durable alternative to conventional printing processes.

Our laser systems enable the non-contact labelling of a wide range of packaging materials - from paper, cardboard and plastic to glass or coated surfaces. Whether flexible packaging, bottles, tubes or labels: laser marking delivers razor-sharp results at high production speeds, without any consumables or drying times. Laser marking can be seamlessly automated by integrating it into existing production lines. This allows you to easily fulfil legal requirements for traceability, product safety and sustainability - with a technology that is low-maintenance and reliable.

Lasering instead of printing

Penteq's laser systems mark materials completely contact-free, so that even sensitive surfaces remain undamaged. Because the laser does not physically touch the workpiece, there is no risk of scratches or damage.

Laser labelling of cardboard packaging - ecological & high-qualityLaser labelling shows its strengths particularly in cardboard packaging:No labels that can peel offNo inks that disrupt the recycling processClear, high-contrast markings directly on the cardboard surfaceIdeal for packaging with high demands on design and sustainabilityWe process a wide variety of cardboard types - from plain shipping boxes to high-quality folding boxes with finishing.

Usual packaging materials

Paper, cardboard and coated surfaces

Plastic packaging (e.g. PET, PE, PP)

Glass bottles and containers

Metal foils and blister packs

Typical applications

Best before date (BBD)

Batch and serial numbers

QR codes, barcodes and DataMatrix codes

Logos, graphics and customisations

Traceability labelling in accordance with EU packaging regulations

High-speed laser labelling of cans

Non-contact direct marking on metal packaging - ideal for serial numbers, best-before dates or logos. Our galvo laser systems enable precise, permanent and environmentally friendly marking with maximum throughput - even on round or moving surfaces.

Your benefits from laser marking at a glance

Durable & abrasion resistant

- Suitable for almost all materials, e.g. cardboard, plastic, paper

- No smudging or fading

Maximum flexibility

- No minimum quantities per label variant

- Customised production directly in the production line ("just-in-time")

- Simple customisation of content (serial numbers, codes, logos)

Forgery-proof and traceable

- Permanently readable QR DataMatrix and barcodes

- Protection against tampering thanks to tamper-proof labelling

High-quality labelling

- High resistance to heat, chemicals and abrasion

Efficient and economical

- High-speed capable - For inline labelling in real time

- Environmentally friendly - No use of inks, solvents or labels

- Reduced operating costs and minimal maintenance

- Non-contact & gentle - Ideal for sensitive packaging materials

| Criterion | Laser labelling | Inkjet printing |

|---|---|---|

| Labelling type | Material removal or colour change (contactless) | Application of liquid ink |

| Durability | Durable, smudge-proof, abrasion-resistant | Varies depending on the ink, often smudge- or water-sensitive |

| Environmental friendliness | No ink, no labels, no waste | Ink consumption, solvent if necessary, label waste |

| Variety of materials | Very suitable for cardboard, paper, plastic, wood, metal | Limited ink application on absorbent or coated surfaces |

| Maintenance & operation | Hardly any consumables, low maintenance | Regular cleaning, ink changes, nozzle problems |

| Printing costs per unit | Low operating costs (no consumables) | Ongoing costs for ink, cleaning and spare parts |

| Attention to detail | Very high, even the smallest lettering & graphics are sharp | Good, but limited for very small or complex motifs |

| Flexibility with content | Fully flexible (variable data, serial numbers, codes, graphics) | Also flexible, especially for large colour areas |

| Investment costs | Higher purchase price, economical in the long term | Lower entry costs, higher running costs |

Laser marking is ideal for companies that prioritise sustainability, durability and precision - especially for cardboard boxes and environmentally friendly packaging. Inkjet printing offers advantages for large-scale colour designs or when the focus is on lower initial investments - but entails higher operating costs and environmental impact.

Do you have special requirements?

We will be happy to advise you individually and find the optimum solution for your packaging line - including integration, test labelling and series production capability.

Suitable products

PenSoft Control

Easy-to-use interface for laser applications

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments