Wristwatches

UKP laser meets manufacture

Laser labelling of watch parts

UKP laser meets manufacture - high-tech for the highest art of watchmaking

In the watch industry, the finest details, absolute precision and high-quality workmanship are essential, especially when it comes to labelling.

Laser labelling offers an incomparably precise, durable and material-friendly solution for marking watch parts.

High-contrast marking for the highest demands. In the world of exclusive watches, every detail counts.

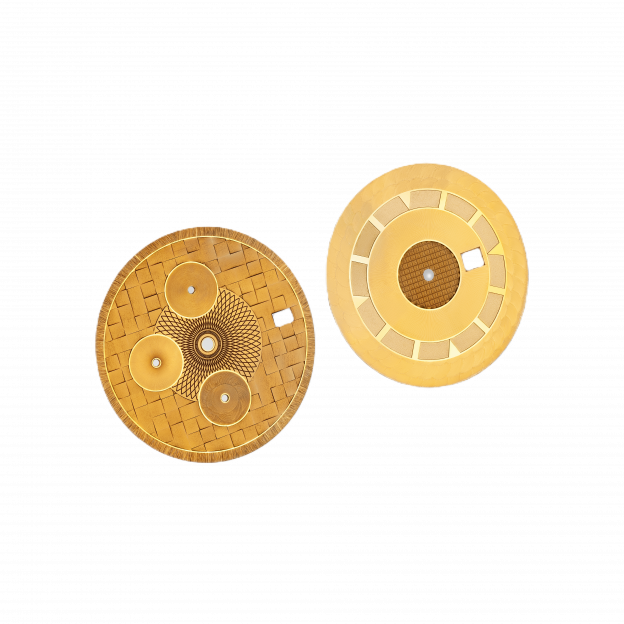

Signolux laser for brass dials

Engraving with a Signolux ultra-short pulse laser (USP) is the most modern form of material processing. It enables extremely precise, micrometre-accurate structures and markings. Signolux USP lasers generate virtually no heat, which makes them ideal for processing heat-sensitive materials such as brass.

This allows complex markings and surface finishes to be realised - without any thermal impairment of the finely machined structures.

Ultra Black Marking with UKP laser Signolux - precision for the watch industry

The non-contact labelling process leaves the mechanical structure of the sensitive parts untouched - ideal for high-quality housings, bases, bridges, rotors or clasps. Laser engraving also impresses with flexibility and repeat accuracy for limited series and personalisation, such as initials or special editions. Our laser systems enable precise, high-contrast and forgery-proof marking that fulfils the highest demands in terms of aesthetics and function - from classic stainless steel cases to gold-plated surfaces or ceramic elements.

Suitable materials for watch parts

Stainless steel (e.g. 316L), titanium, brass, gold, silver, platinum

Ceramic, anodised aluminium, sapphire crystal (with Signolux)

Typical applications

Engraving of serial numbers and references

Manufacturer logos and brand labelling

Laser engraving on movement bridges and rotors

Customised lettering for limited editions

Design of dials and case backs

Finest engravings with high edge definition - also for microtypography

Security markings such as micro lettering or micro data matrix codes

Decorative structures such as sunburst, guilloché or textures

USP lasers (femtosecond or picosecond lasers) generate almost no heat, which makes them ideal for heat-sensitive materials such as brass. This allows complex markings and surface finishes to be realised - without any thermal damage to the finely crafted structures.

Why Signolux UKP lasers for brass dials?

Tradition and technology in perfect harmony

In a world where precision, aesthetics and longevity are crucial, modern technologies such as the ultra-short pulse laser (USP) merge with the classic craftsmanship of watchmaking to create a new standard: technical excellence with emotional depth. While experienced watchmakers assemble the heart of every watch - the movement - with dedication, the USP laser offers unrivalled possibilities for the high-precision finishing of components such as dials, cases or oscillating weights.

Advantages of Signolux laser marking for watch parts

Ultra-precise engravings

- Labelling with logos, microtexts, serial numbers and codes

- Outstanding labelling quality

- High contrast thanks to ultra black marking

- Clean deep engraving

Durable & abrasion resistant

- For lifelong labelling

- Uniquely identifiable through Micro Data Matrix Codes

- Outstanding labelling quality

- High contrast and high readability

- Can be labelled quickly: by engraving or colour change

Your partner for the finest laser engravings

With our UKP laser technology, we apply permanent, non-ageing markings to your luxury watches - discreetly, precisely and unmistakably. From the dial to the case back.

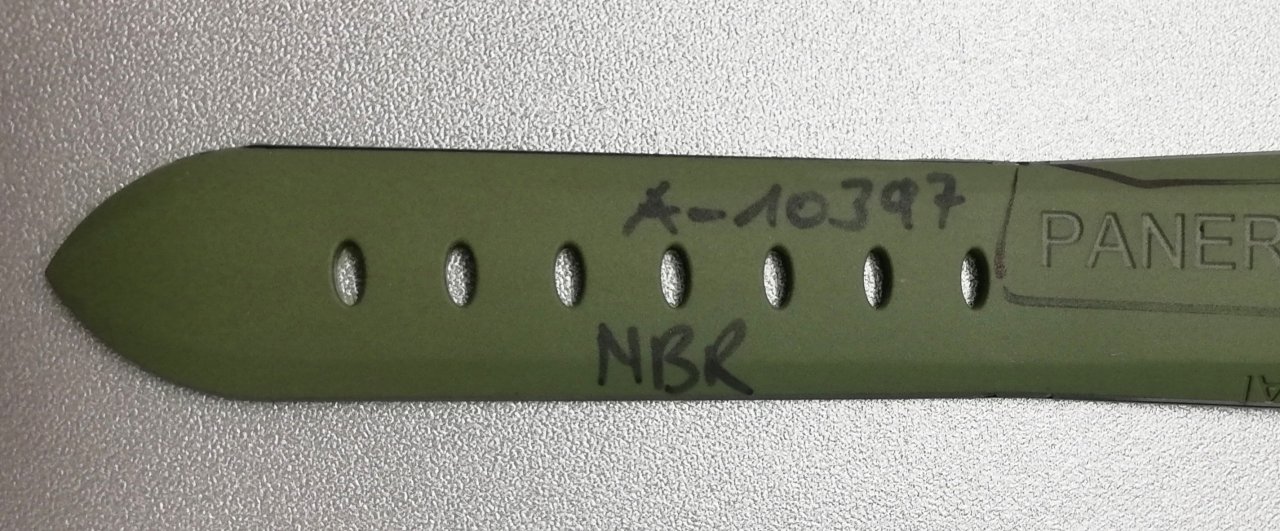

Laser labelling of watch straps - precise, elegant, individual

A watch strap is more than just a functional element - it is an expression of style, identity and value. With modern laser labelling, watch straps made from a wide variety of materials can be finished precisely, permanently and aesthetically: from finely engraved logos and serial numbers to individual dedications or patterns.

Stainless steel & titanium - high-contrast engravings without material deformation

Leather - gentle laser embossing for lettering, logos or textures

Rubber & silicone - precise, permanent marking without abrasion

Ceramic & carbon - smooth, fine lines with a maximum level of detail

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

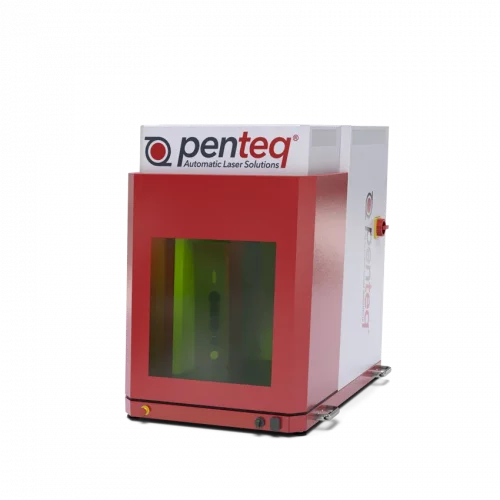

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

LG500 A Double shutter

Automatic loading system for large workpieces

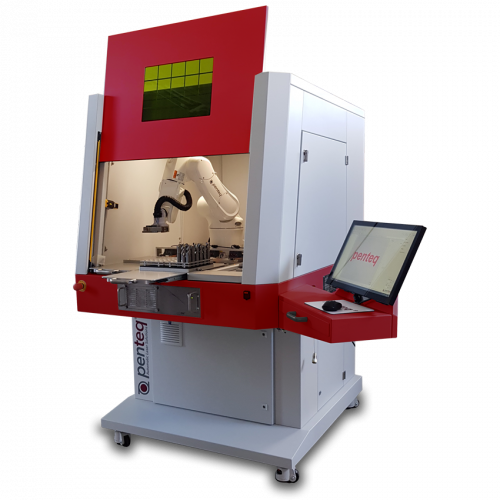

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Integration station

Laser system for easy integration into conveyors

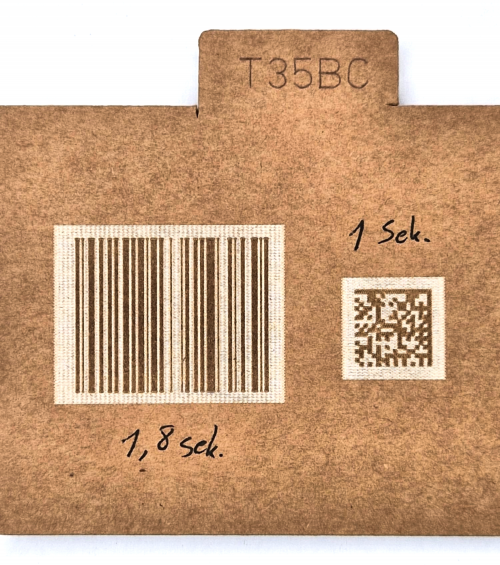

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.