SG200 Weld - your solution for dynamic and precise laser welding

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

You can also visit the SG200 Weld on our

High-precision laser welding with the SG200 Weld

The SG200 Weld laser welding system provides an easy and cost-effective introduction to laser welding. It combines precision and flexibility and is ideal for small and medium-sized workpieces. With a footprint of only around one square metre, including laser fume extraction, the system offers a space-saving solution for a wide range of applications.

The ergonomic seated workstation and the programmable scanner unit enable dynamic welding at different process points without having to move the workpiece or the welding head. The reduction of non-productive times to a minimum and the ability to graphically position welding patterns according to strength make the SG200 Weld an ideal choice for demanding welding tasks.

Discover the possibilities of modern scanner laser welding

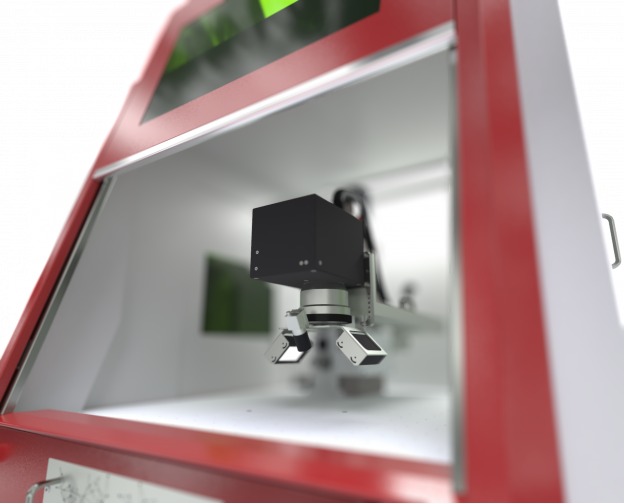

Dynamic Precision Welding (DPW)

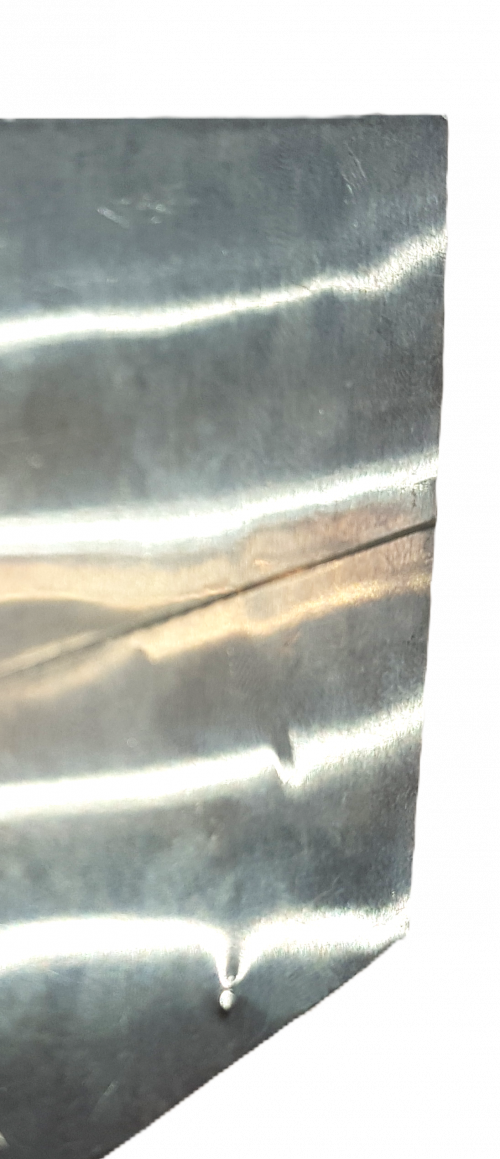

The DPW system combines innovative technology with maximum precision and efficiency. Movable mirrors enable fast and economical beam guidance, ensuring precise weld seams even with complex materials. The inline camera captures the workpiece surface directly, avoids distortions and provides an exact image of the work zone. With the help of AI-based software, the system automatically corrects deviations and minimises rejects. This innovative combination forms the basis for high-precision, reliable welding for a wide range of production requirements.

Modern scanner welding

Faster, more precise and more economical than conventional laser welding processes thanks to beam guidance via movable mirrors.

The inline camera looks directly at the workpiece surface via the mirrors without any loss of accuracy or distortion as would be the case with an offline camera.

The working area is scanned in the grid by the mirror movements and recorded by the camera in the beam path. A correct image of the complete work zone is then compiled from this. This provides the basis for high-precision welding at exactly the desired positions.

Fast automatic door

The large automatic door enables quick and safe access to the work area. Its precisely adjustable stroke reduces non-productive time and optimises production efficiency. The CE-certified laser safety window ensures maximum safety and a clear view of the machining process.

Advanced laser technology

The SG200 Weld supports powerful single-mode and multi-mode fibre lasers, either in CW or pulsed mode. This advanced technology ensures optimum results and flexibility for a wide range of materials and applications.

Ready for data exchange

Thanks to modern interfaces, the SG200 Weld can be seamlessly integrated into digital production processes. It enables efficient data transfer, process monitoring and customisation to individual requirements.

User-friendly operation

The intuitive software offers a user-friendly interface for simple programming and control.

Graphically positionable welding patterns ensure precise results without the need for extensive prior knowledge.

Sturdy castor feet

The robust castor feet ensure stability during operation and also allow the system to be repositioned easily. Perfect for flexible and changing production requirements.

| Workspace dimensions | 900 x 600 x 150 mm (WxDxH) |

| Active medium | Yb fibre laser, UV laser, Signolux, CO₂ laser |

| Standard performance | 20, 30, 50, 100, 150, 300 watts |

| Simple field of work | 80 x 80 mm (other sizes on request) |

| Maximum workpiece weight | 50 kg |

| Security | Laser class 1 |

| Dimensions | 100 x 1500 x 1650 mm (WxDxH) |

| Weight | approx. 700 kg |

- Pivot axis

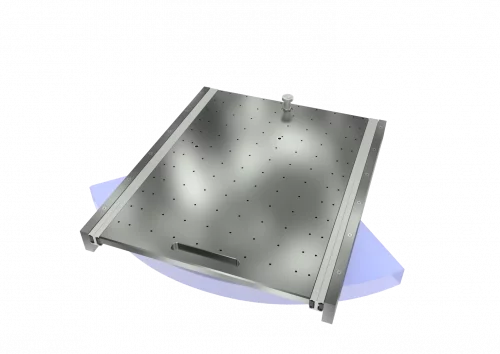

- Extendable table

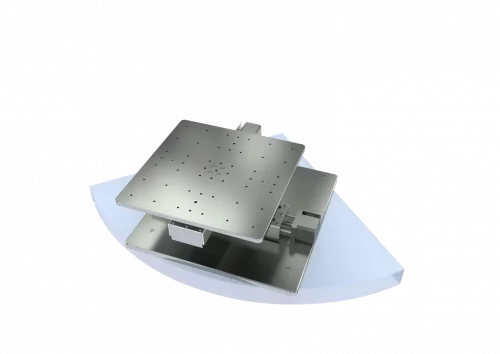

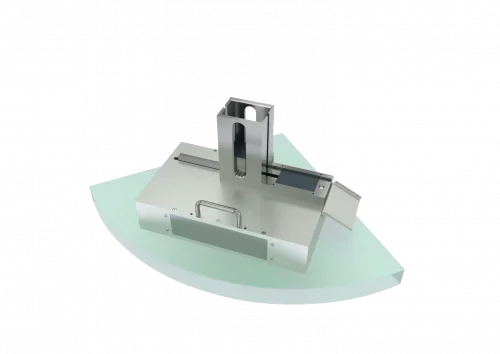

- X/Y table

- Robot transfer

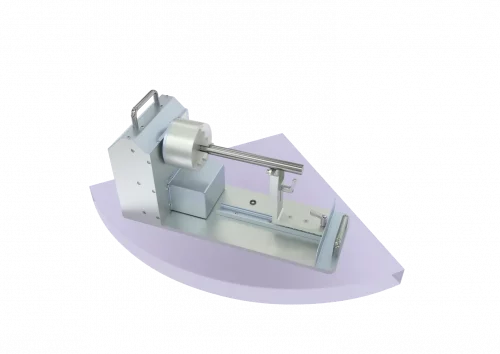

- Linear conveyor

- Ring conveyor

- Automatic equalisation of focus position

Software

- Pensoft DPW

- Pensoft Connect - ERP connection

- Penteq App Development

Accessories

- DMC Camera - VisionSystem Verifier

- Pilot laser

- Laser fume extraction

- Manual Y-axis

- Foot switch

- Monitor on swivel arm

- Hand scanner for codes

- touch screen

- Bad parts box

- 3-stage status light

- Fiberline F150 Q-CW

- Fiberline F300 Q-CW

- Fiberline F500

- Fiberline F1000

- Fiberline F2000

Matching products

FM XY table

The automatically movable X/Y table enables the marking field to be enlarged in the X and Y directions

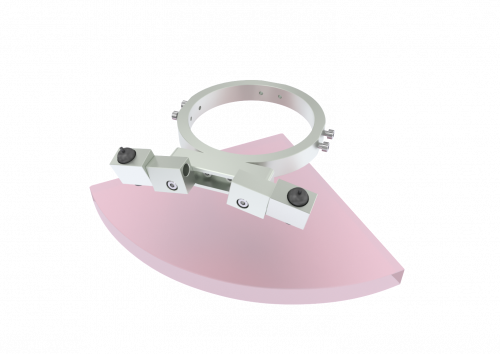

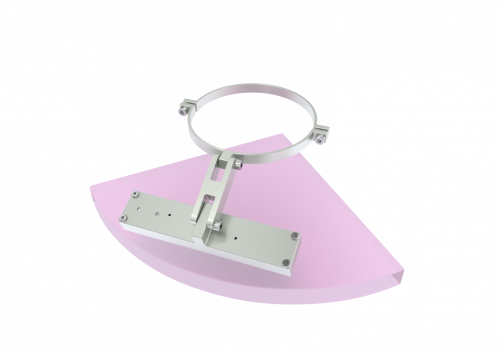

FM Rotary axis

The rotary axis function module (dividing head) is used for segmental labelling of the lateral surface on cylindrical components.

FM Extendable table

The door can be opened completely and the support table pulled out towards the operator for adjustment and set-up work, as well as for picking up large or heavy parts.

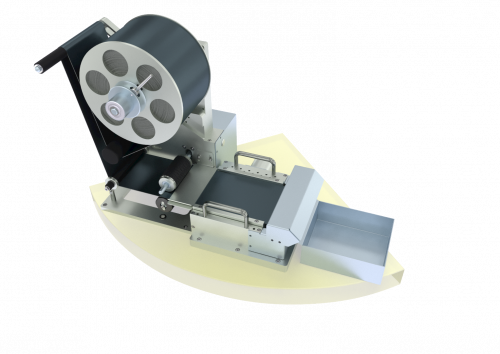

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

PenSoft Control

Easy-to-use interface for laser applications

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications

Applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Watch components

Precisely joining what belongs together

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling