Laser welding batteries

Laser welding of battery cells

Efficient connection technology for high-performance battery systems

Laser welding has established itself as the leading joining technology in battery cell production - especially where precision, speed and thermal control are crucial. Our customised solutions enable reliable, reproducible welded joints for cylindrical, prismatic and pouch cells.

DPW - Laser welding of battery cells with dynamic geometry recognition

Laser welding of busbars - efficiency and precision for electrical connections

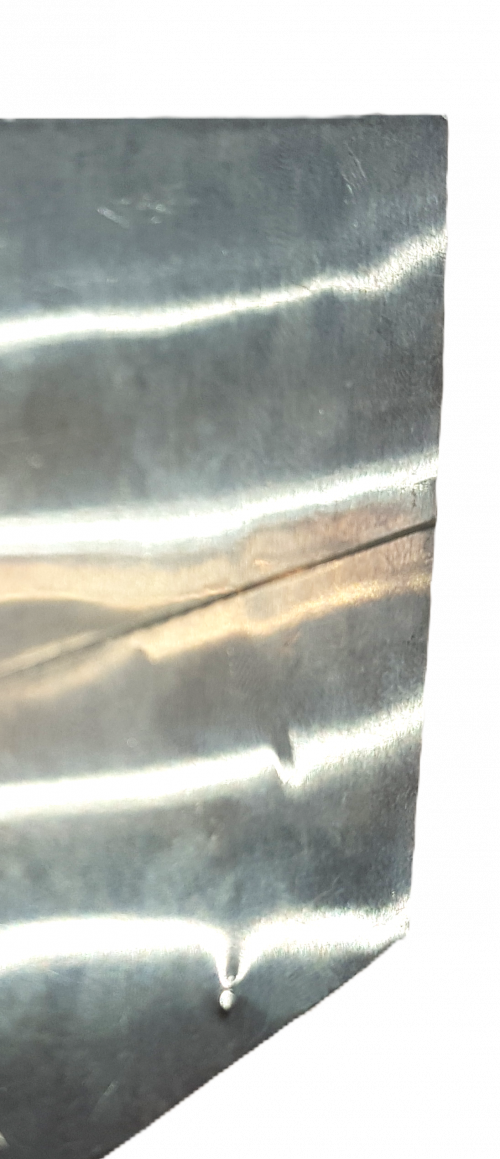

Laser welding of busbars is a high-precision joining process that is primarily used in electromobility, power electronics and energy distribution. Busbars are used for the low-loss transmission of high currents, which is why their connection technology must fulfil the highest requirements in terms of electrical conductivity, mechanical stability and thermal load capacity. By using laser technology, copper and aluminium busbars can be joined together efficiently, quickly and in a material-friendly manner.

The process offers numerous advantages over conventional welding methods, is contactless and wear-free: the laser works without physical tool contact, which eliminates tool wear and increases process reliability.

High precision: The focussed laser beam enables exact weld seams with minimal heat input, which reduces material deformation and improves quality.

Process speed: Laser welding enables short cycle times and is therefore particularly suitable for automated production lines.

Variety of geometries: Complex welding configurations such as overlap or T-joints can be realised precisely. A typical field of application is the connection of multi-layer copper conductors in battery systems or the welding of aluminium busbars in inverters. A high-power fibre laser is often used here, depending on the material and application. Due to the increasing demand for electrical energy transmission in modern applications, laser welding of busbars is becoming increasingly important - as a key technology for durable, efficient electrical connections.

Dynamic Precision Welding - Process reliability and precision through adaptive welding strategies

In modern battery cell production, the requirements for precision, flexibility and process reliability are constantly increasing - especially when it comes to the interconnection of cell connectors and current arresters.

Laser welding with dynamic geometry recognition is a key technology for meeting these requirements.

Functional principle Dynamic Precision Welding:

Dynamic geometry recognition is based on a combination of camera technology, AI-supported image processing in real time and dynamically adaptable laser path guidance by scanners . Before the welding process, the actual position and geometry of the cell contacts, e.g. tab positions or arrester layers, are precisely recognised. Deviations from the target position (e.g. due to component tolerances, heat distortion or layer displacement) are taken into account and the welding process is automatically adjusted. This enables highly accurate and reliable contacting, even with varying component geometries.

Battery packs are connected using conductive bridges (busbars). During the manufacture of these bridges, production-related geometric deviations can occur, which can lead to rejects during the welding process. In combination with the DPW process, AI-supported software can recognise these deviations and automatically correct the welding process.

Advantages of DPW scanner laser welding in battery cell production

Flexible and economical

- Flexible weld seam geometry for perfect adaptation to specific requirements

- Suitable for aluminium, copper, nickel, steel and much more

- Ideal for integration into production lines for automated series production

Minimal heat input

- Protects temperature-sensitive cell materials

- No distortion of the joining partner

Precise

- Ideal for delicate cell contacts and tight tolerances

- Avoids production errors and reduces rejects

- Definable welding contour

Resistant

- Outstanding seam quality & safety

- Clean, reproducible weld seams with high strength

Typical applications:

E-mobility: cell contacting in vehicle batteries

Stationary energy storage: Module production for PV and wind systems

Power tools: Connection of compact cell modules

Medical technology & aviation: special applications with the highest quality requirements

🔍 Submillimetre-precise positioning of the weld seam

⚙️ Automatic compensation of tolerances & misalignment

📈 Reduction of rejects and rework

🔄 Inline adjustment of the laser path in real time

🧩 Compatible with com plex cell layouts (e.g. stacked or offset arrangement) Typical applications Cell connection for pouch cells with flexible tab Interconnection of cylindrical cells with variable tab position e.g. stacked or offset arrangement)

Typical applications Cell connection for pouch cells with flexible tab

Interconnection of cylindrical cells with variable tab positionModule production with a high number of cells and tight packing density

Adaptive welding for pre-positioned but not precisely fixed cell components

Integration into automated lines

The system can be fully integrated into automated production lines. It can be coupled with and supports standard PLC/MES interfaces:

Closed-loop process control

Seam monitoring & welding data logging

Recipe management for different cell types

Conclusion: Laser welding with dynamic geometry recognition is a decisive technological advantage for manufacturers who want to produce complex, high-density or variably configured battery systems efficiently and reliably.

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

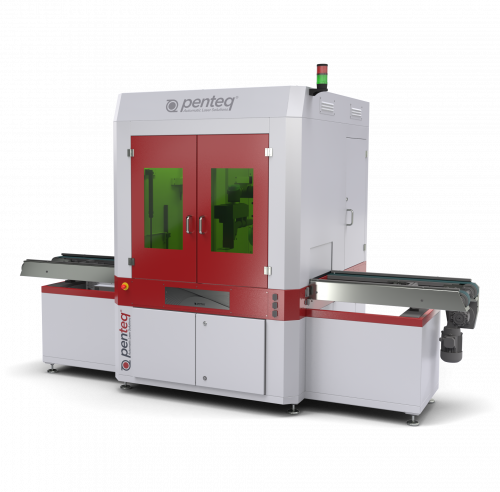

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Rotary table laser LG200 RT

For maximum production speed

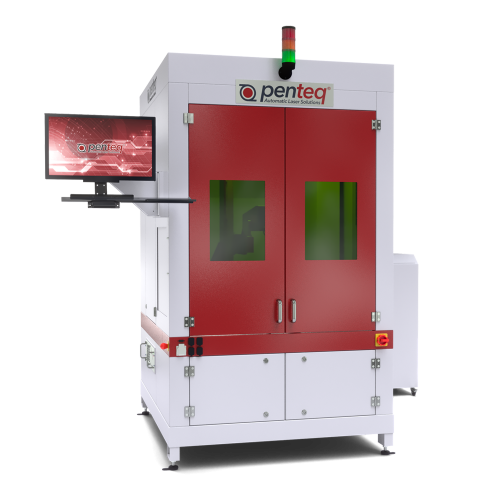

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

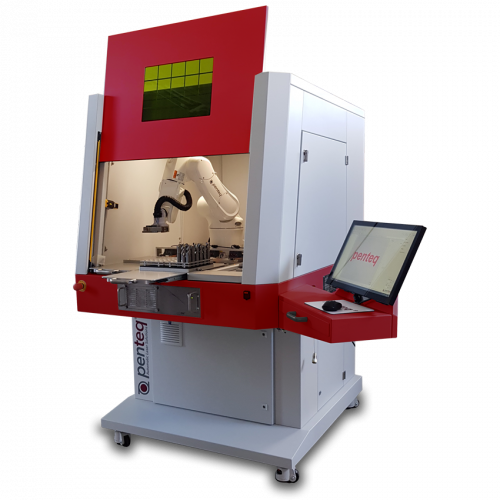

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

SG 500 RoboLaser

Flexibility through laser robots

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Industries

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components