BOFA - Fume extraction systems for laser applications

Reliably extract and filter laser smoke, laser particles and fumes

Why is a special laser smoke extraction system so important?

When lasers are used in industrial production, harmful vapours and particles are produced, which are referred to as laser fumes or emissions. These invisible dangers are often underestimated, but can cause lasting damage to both man and machine. Depending on the material being processed, laser fumes contain ultra-fine particles, possibly toxic gases and potentially carcinogenic substances. Without effective extraction, these enter the airways of employees and can lead to acute discomfort or long-term damage to health. A professional extraction system reliably filters these pollutants out of the air and thus ensures a safe working environment.

The fine particles are not only deposited in the environment, but also in sensitive machine parts. Without adequate extraction, this can lead to malfunctions, loss of quality and expensive repairs. Targeted extraction extends the service life of the machine and maintains process reliability. Strict health and safety and environmental regulations require the use of suitable extraction systems. With an extraction system specially developed for laser applications, companies not only fulfil these requirements, but also demonstrate responsibility towards employees and the environment.

The result: more safety, better quality, longer service life. An extraction system specially designed for laser applications is not a luxury, but an essential component of safe and economical laser operation. It protects people, machines and the environment - and pays off in every respect in the long term.

Overview of laser smoke extraction systems:

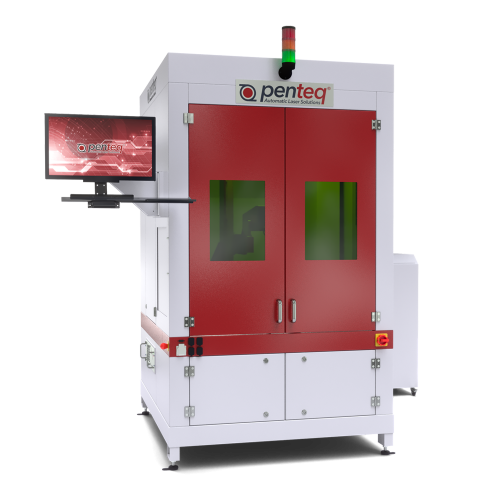

AD Access (PE1)

BOFA's AD Access extraction and filtration system effectively removes harmful vapours and particles generated during the laser marking process. A three-stage filter ensures a dust-free work area is maintained and the system helps to protect valuable equipment, maintain higher quality marking and reduce the number of rejects and contaminants.

Standard features:

Digital flow control system

High airflow and high pressure blower

Durable low-cost replacement filters

Low noise level

DeepPleat pre-filter

Small dimensions

AD 350R (PE2)

The Advantage 350R extraction and filtration system is a model specially developed for Penteq system integration and effectively removes harmful vapours and particles generated during the laser marking process. By maintaining a dust-free work area, the system helps to protect valuable equipment, increase production quality and reduce waste and contamination.

Standard features:

Digital flow control system

High airflow and high pressure blower

Low-cost replacement filter

Low noise level

Filter status indicator

AD 350 (PE4)

BOFA's Advantage 350 extraction and filtration system effectively removes harmful vapours and particles generated during the laser marking process. By maintaining a dust-free work area, the system helps to protect valuable equipment, maintain higher quality marking and reduce the number of rejects and contaminants.

Standard features:

Digital flow control system

High airflow and high pressure blower

Low-cost replacement filter

Low noise level

Filter status indicator

AD Nano Plus (PE3)

The AD Nano+ (PE3) is a medium sized laser fume extraction system for light to medium duty laser applications. This cost-effective solution offers features that are normally only available in larger models and is therefore ideal for installations where space is limited. It is characterised by low noise levels in a small footprint and features durable, cost-effective filter cartridges.

AD Oracle iQ (PE6)

Ideal for: Selective laser melting, selective laser sintering, laser engraving, laser cutting, laser welding, laser coding and marking. The AD Oracle iQ model combines a wide range of functions, including the intelligent operating system (iQ), in a unique system. This is suitable for a wide range of laser applications. High contrast display, real-time airflow measurement and independent filter condition monitoring combined with a high airflow blower and remote diagnostics via USB.

Our advice for the right solution for every application

When it comes to the right laser fume extraction system, factors such as the materials (plastic, metal, wood or composite materials) that can release different pollutants must be taken into account. From occasional use to series production, the volume and concentration of the resulting emissions vary considerably. The spatial conditions within the laser safety cabin also influence the choice of system. Our experts will support you in the professional design of your extraction system. Together, we will analyse your application and recommend a tailor-made system that meets all requirements, offers maximum efficiency and can be flexibly integrated into your processes.

Benefit from our experience - for maximum safety, efficiency and sustainability.

👉 Get a no-obligation consultation now!

We look forward to receiving your enquiry and working with you to find the optimum solution for your laser application.

Matching products

Laser workstation LG 200

Modularity as a pioneering concept

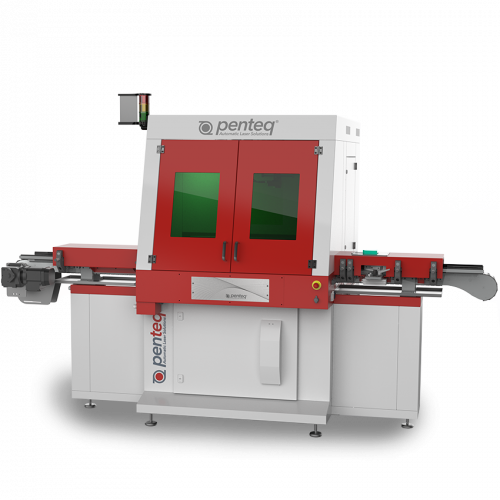

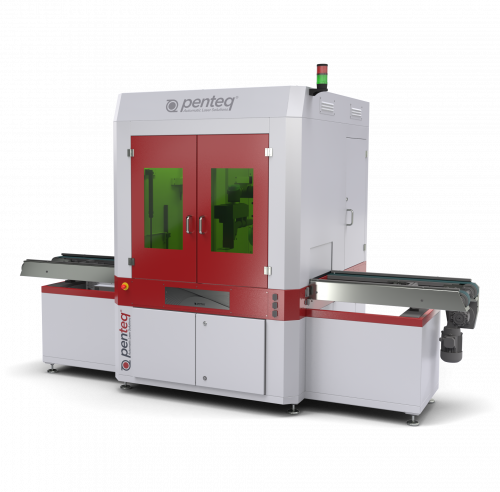

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

BellCape mobile laser

Mobility meets precision for mobile laser labelling

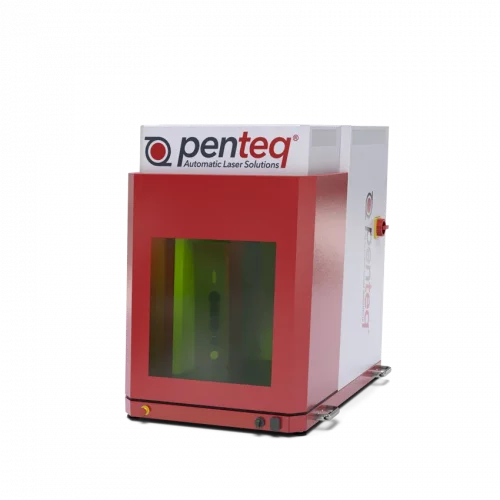

Smartlaser LG20

The intuitive system for professional results

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

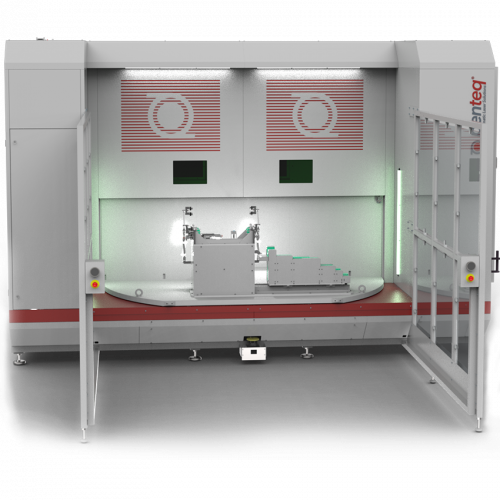

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

Type plate laser machine LG200 PL SB10

for all types of signs

Type plate laser machine LG300 PL SB50

For all types of signs

Type plate laser machine LG200 PL SB50

For all types of signs

Laser system with pocket wheel

Automatic laser system with optimised material flow

LG500 A Double shutter

Automatic loading system for large workpieces

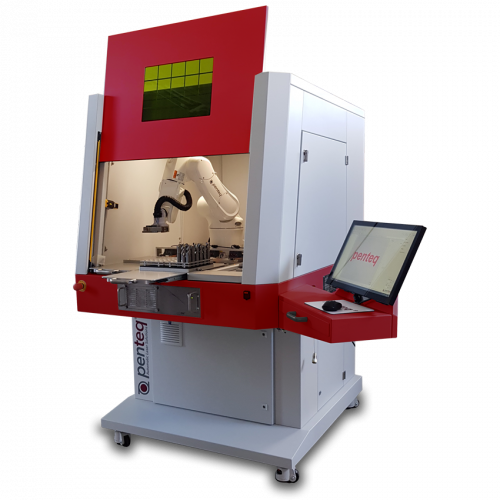

SG 500 RoboLaser

Flexibility through laser robots

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

Turntable Laser system with robot

Turntable system with manipulation and laser robot

Applications

Stripping

Stripping & stripping of copper wires for the electronics industry

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

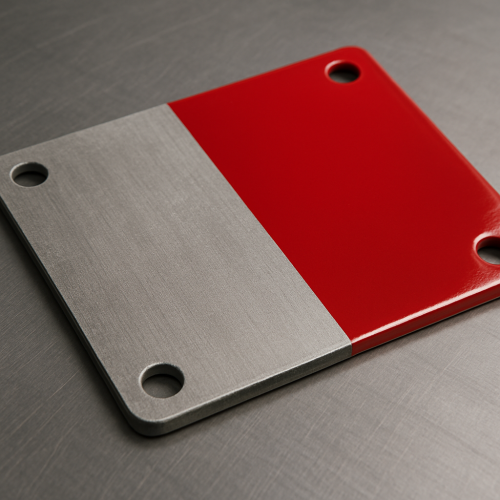

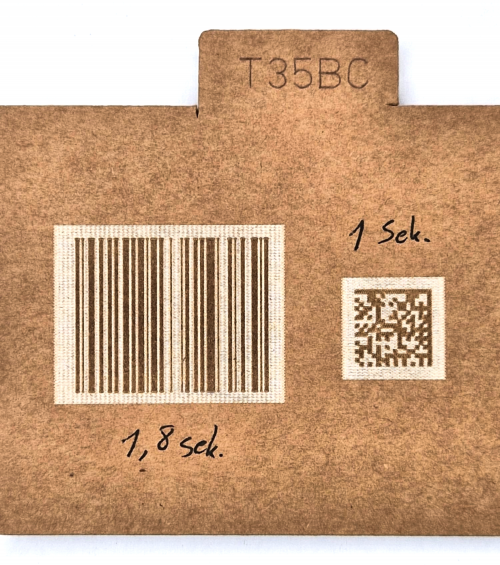

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Cutting tools

Flexible and durable laser labelling

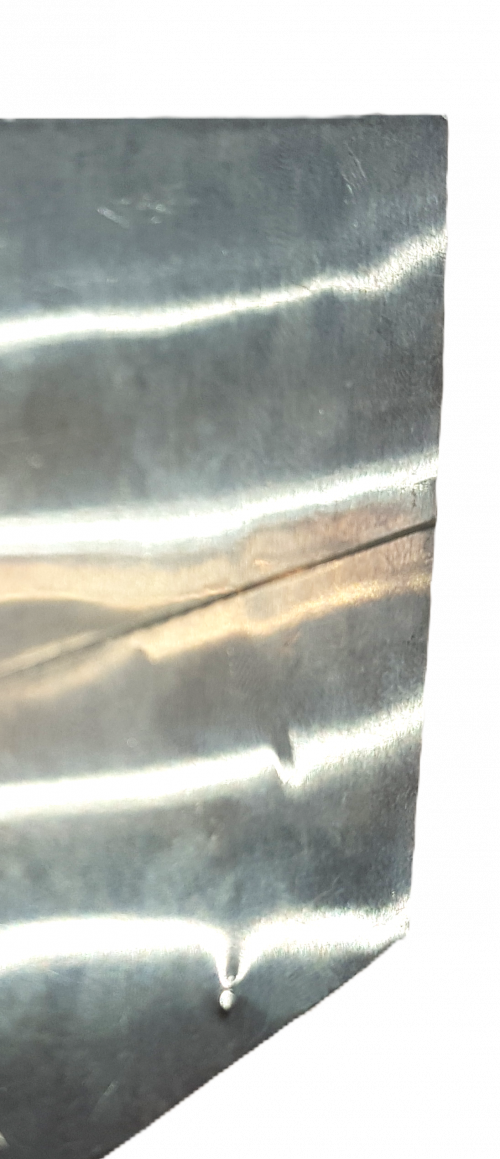

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

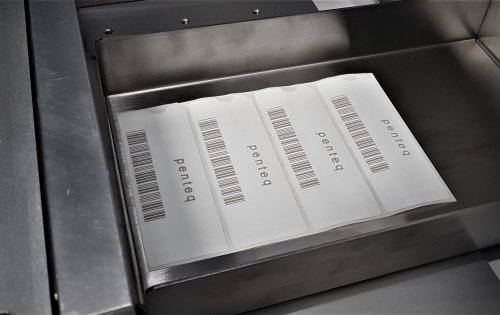

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Watch components

Precisely joining what belongs together

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling