Cutting tools

Laser marking of cutting tools

a precise, efficient and permanent method

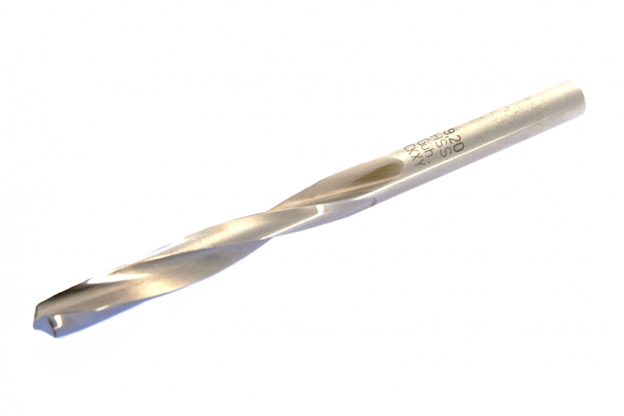

The permanent and precise labelling of cutting tools is a decisive factor in modern production. Using state-of-the-art laser technology, we offer a high-resolution, wear-resistant and traceable labelling solution for tools of all kinds, from milling cutters and drills to special tools.

Automatic in the highest quality

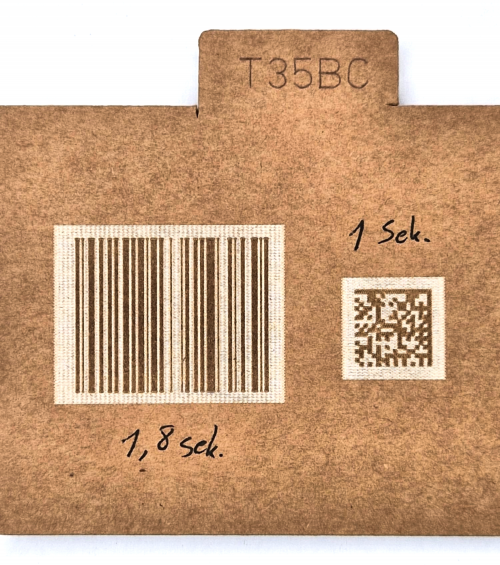

Our laser markings meet the highest requirements in terms of legibility, durability and customisability. Serial numbers, logos, QR codes or customer-specific information - the labelling is gentle on the material, burr-free and does not impair the tool function. Lasers also deliver razor-sharp results on hardened or coated surfaces. Thanks to automated processes and flexible handling, we are able to mark both small batches and large quantities economically - quickly, reliably and with consistently high quality.

Thanks to automated processes and flexible handling, we are able to economically label both small batches and large quantities - quickly, reliably and with consistently high quality.

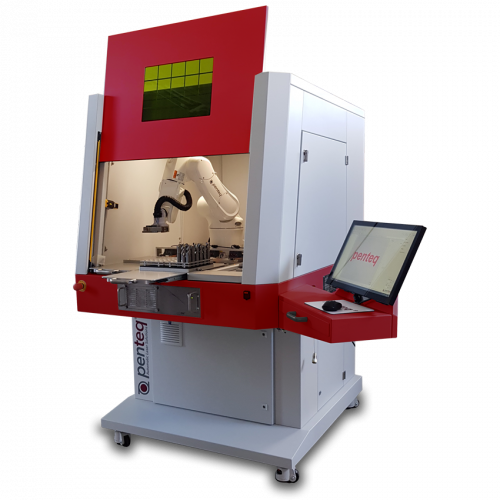

Automated laser marking with workpiece pallets

For maximum efficiency in the marking process, we rely on the automated feeding of tools via workpiece pallets. The tools are precisely positioned in defined holders, gripped by the integrated robot and fed to the laser - ideal for series production and end-to-end automation. This minimises manual handling, reduces sources of error and enables consistently high process reliability with high output.

The efficient management of cutting tools is achieved by labelling with Data Matrix Codes (DMC), which are linked to a database and thus provide comprehensive data. This enables digital identification throughout the entire service life. The documentation of all processes, such as the number of regrinds, enables planning and analyses with high savings potential.

Our laser machines are equipped with standardised interfaces so that individual markings can be taken directly from digital templates and automatically applied to the tools. Customised adaptations can be implemented quickly thanks to our in-house software development. This enables high efficiency and an optimised production process.

Data Matrix code for traceability

A particular focus is on laser labelling with data matrix codes for unique tool identification. These two-dimensional codes enable seamless traceability throughout the entire life cycle - from manufacture to use in production. In conjunction with modern tool management systems, every tool can be automatically recorded, monitored and efficiently managed. In this way, we create the basis for digitalised, networked production with maximum transparency.

Laser labelling on inserts is an established method. Unique labelling with the type designation or a machine-readable data matrix code enables identification.

Thanks to their small spot size, new types of laser are able to permanently mark even very small inserts.

Laser marking is an essential part of modern precision machining of cutting tools. It offers a durable, precise and flexible marking solution that fulfils both functional and aesthetic requirements. By combining precision, material protection and sustainability, this technology makes a significant contribution to quality assurance and traceability in production.

Advantages

Flexible and economical

- Labelling with logos, plain text, serial numbers and codes

- Fine, permanent markings with high accuracy

- Suitable for carbide, HSS (high-speed steel) or cermet indexable inserts

Sustainable

- The machine uses no consumables such as ink or etching chemicals, making it environmentally friendly and economical.

Precise

- Outstanding labelling quality

- High contrast and high read reliability with Ultra Black Marking

Resistant

- Highly resistant to abrasion and chemicals

- Quality assurance and traceability through data matrix codes

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

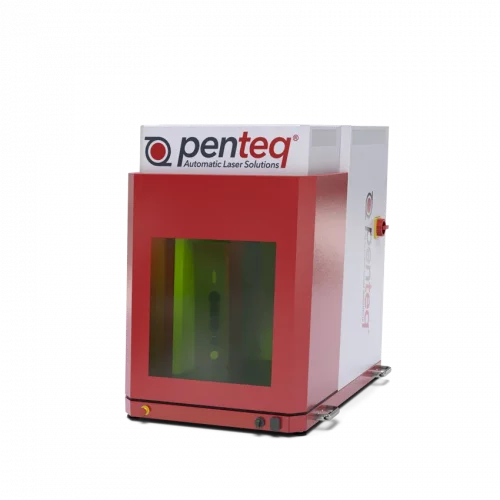

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

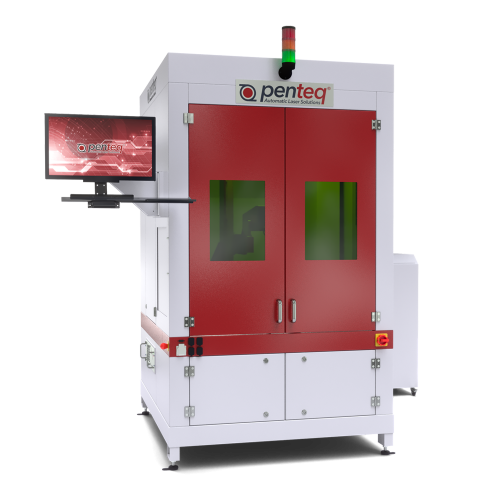

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

Signolux UKP Pico

Precision & quality for the highest demands

LG500 A Double shutter

Automatic loading system for large workpieces

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust