Electromobility - Batteries

Laser labelling of batteries

Electromobility - Batteries

Penteq offers laser applications for electromobility, especially for batteries. These include laser cleaning to prepare bonding and laser welding of metal components. These technologies improve battery performance and extend service life

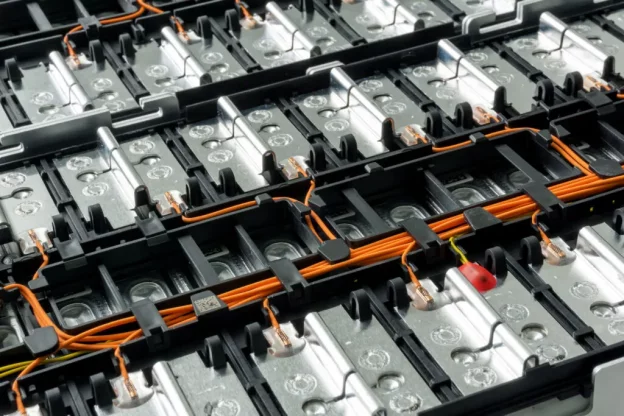

Batteries

The preparation for bonding batteries is becoming increasingly important. Modern adhesives and sealants improve battery performance and extend service life.

The use of state-of-the-art laser technology provides the solution to a number of challenges in order to ensure flawless and long-lasting function, reliably removing all kinds of contamination from the components to be connected without leaving any residue.

battery cells and module assembly as well as EV electronic components and the integration of battery packs

The cleaning process is fast and reliable and offers the opportunity to remove contamination such as paint residues, lubricants and various coatings from the exact areas required.

Laser cleaning of battery cells in preparation for welding

In battery module and pack production, the connection of battery cells with aluminium or copper busbars is of central importance. For reliable electrical conductivity and mechanical strength, it is crucial that the contact surfaces of the cell and busbar are absolutely clean and free of oxides, oils or particles. Laser cleaning offers a precise and efficient solution here. Targeted laser radiation is used to selectively remove oxide layers, organic residues and protective layers from aluminium or copper surfaces - contact-free, dry and without chemical additives. The result is a metallically pure surface that creates the ideal conditions for high-quality laser welded joints.

For aluminium busbars in particular, which oxidise very quickly, laser-based cleaning directly before the welding process is a decisive factor for process reliability and reproducibility. Copper, which reacts sensitively to contamination, also benefits from gentle and controlled laser cleaning. Thanks to the high precision, even complex geometries, narrow tolerance ranges or hard-to-reach areas can be reliably processed. The process can be fully automated and ideally integrated into existing production lines, making it the preferred technology in automated e-mobility production.

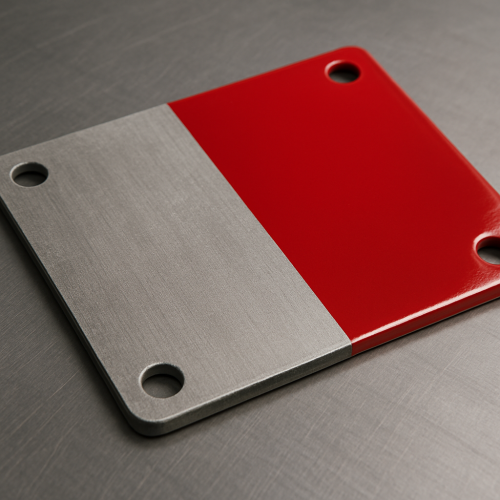

Laser cleaning and laser labelling in a single operation

Clean surfaces - high-contrast, durable markingsInmany industrial applications, the quality of a laser marking is largely dependent on the cleanliness of the surface. Contamination such as oil, grease, oxides or protective coatings can impair the contrast of the marking, reduce the legibility of DMC codes or even jeopardise the long-term durability of the marking.our laser systems offer the option of laser-based cleaning of the areas to be marked in advance - inline and fully automated.

Residues, oxide layers or thin coatings are removed in a targeted manner without damaging the base material. Laser marking then takes place seamlessly on a clean, metallically pure surface - for optimum adhesion, maximum contrast and maximum process reliability.

Laser marking of battery cells

Labelling battery cells with standard-compliant data matrix codes (ECC200) enables each individual battery cell to be traced end-to-end. The machine-readable codes are permanent over the entire life cycle and are resistant to all influences. Laser marking offers many advantages over conventional methods, such as durability, good readability thanks to high contrast and a fast and automatable process. To increase the information density, rectangular codes can be applied to round battery cells. This avoids the readability problems caused by the curvature of the surface and ensures reliable reading.

Suitable products

PenSoft Control

Easy-to-use interface for laser applications

OEM fibreline

Ready-to-install laser for numerous applications

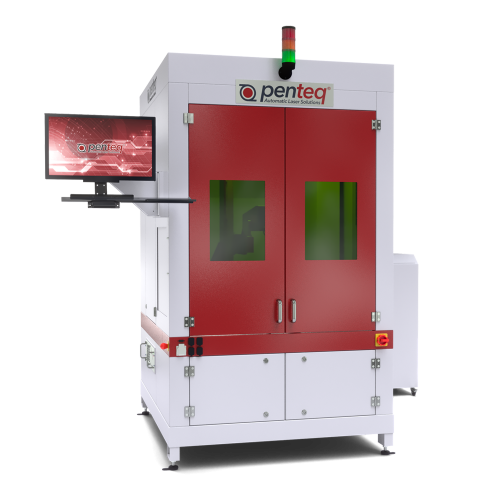

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

Laser workstation LG 500

the top class for XL formats in laser processing

SG 500 RoboLaser

Flexibility through laser robots

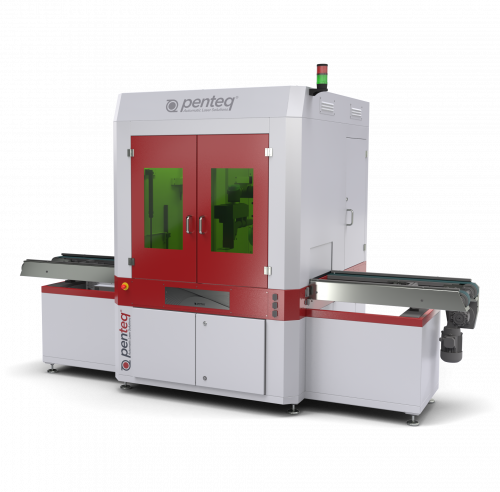

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG500 A Double shutter

Automatic loading system for large workpieces

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

PenSoft Connect IP

Software für die Typenschildproduktion

OEM fibreline high power

Ready-to-install laser for numerous applications

Further applications

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Rust removal

Efficient laser cleaning of corroded surfaces