White goods

Precise, durable and economical solution for labelling white goods

White goods

Laser labelling of white goods - precision and durability

Laser marking has established itself as a precise, durable and economical solution for labelling white goods. Whether serial numbers, logos, control panels or symbols - we use state-of-the-art laser technology to ensure razor-sharp markings on plastic and metal surfaces.

Highest quality for your household appliances

White goods are large household appliances such as washing machines, refrigerators, dishwashers, cookers, ovens and dryers.

These appliances require clear, durable labelling - whether for product identification, user guidance or brand communication.

State-of-the-art lasers are increasingly being used, especially to ensure the exclusive design of the devices. These include, for example, ultrashort pulse lasers in the pico- or femtosecond regime as well as lasers in the UV wavelength range. For example, stainless steel panels need to be labelled with logos with as much contrast as possible without increasing the material's susceptibility to corrosion.

Enhance with logos

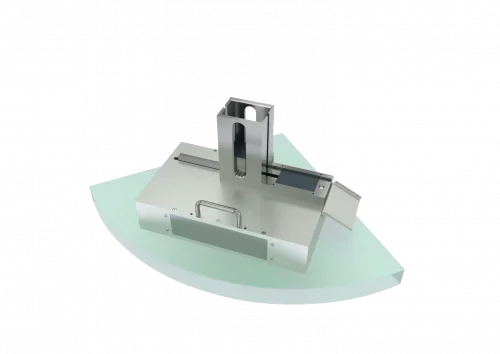

Plastic panels often have free-form surfaces that can be labelled in 3D without distortion. The 3D option, which is available for all lasers, can be used for this purpose. In addition to selecting the right beam source, the optical configuration of the laser also plays a decisive role in achieving the optimum result. As these are usually series products in large quantities, consistent quality is essential. This can be guaranteed by integrated vision systems, for example.

Ultra Black marking and engraving on stainless steel panels

Ultra Black Marking is a special process for permanent, deep black labelling of stainless steel. Extremely short laser pulses in the picosecond range change the surface locally without removing any significant material. The resulting black colouring is based on a nanostructuring of the surface which remains colour-stable and low-reflection under any viewing angle. This is a significant advantage when operating devices with integrated touch elements.

With USP laser engraving, the material is removed in a targeted manner, allowing perfect filigree structures, symbols or lettering to be applied to the stainless steel panel.

Advantages of laser labelling for white goods

- Durable and abrasion-resistant - labelling that looks classy even after years of intensive use

- Non-contact and gentle on the material - no damage to the material surface

- Maximum precision - Ideal for fine lines, small font sizes and complex designs of the highest quality

- Environmentally friendly - No use of inks, solvents or labels

- Flexible integration - Can also be integrated into automated production lines

Typical areas of application

- Type plates & serial numbers

- Key symbols and control panels

- Manufacturer logos and brand labelling

- Safety and test symbols

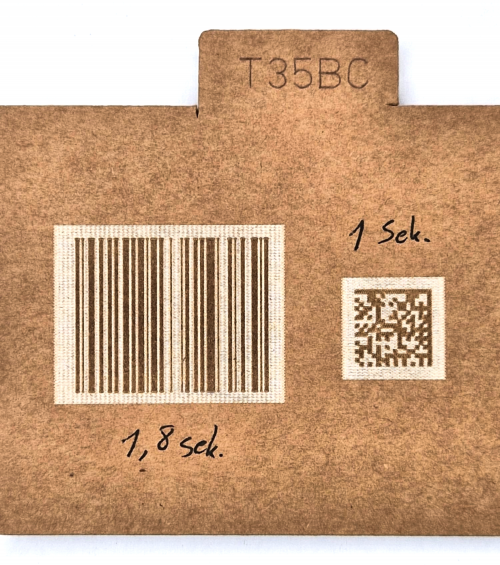

- QR codes & DataMatrix codes for traceability

Suitable materials

- Powder-coated sheet metal

- Stainless steel

- ABS, PC, PA and other plastics

- Anodised aluminium

- Glass fronts transparent, coloured or with colour backing

Get advice now

With years of experience in industrial laser coding, we offer:

- Customised advice

- Sample labelling & tests

- Integration into existing production lines

- Integration into the software

- Fast implementation & series production

- Highest quality standards

Talk to us about your requirements! Together we will develop the perfect solution for your laser labelling of white goods.

Suitable products

PenSoft Control

Easy-to-use interface for laser applications

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

Signolux UKP Pico

Precision & quality for the highest demands

Smartlaser LG20

The intuitive system for professional results

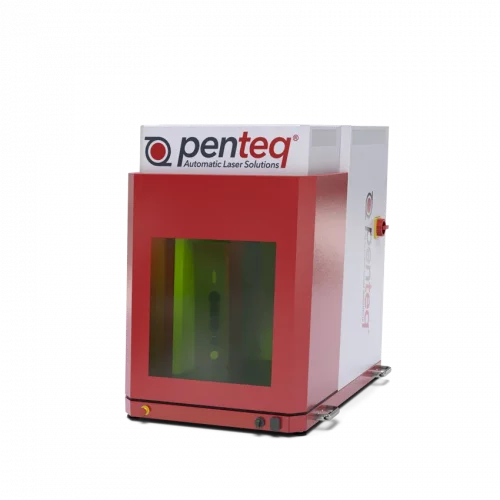

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Laser workstation LG 200

Modularity as a pioneering concept

Rotary table laser LG200 RT

For maximum production speed

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

SG 500 RoboLaser

Flexibility through laser robots

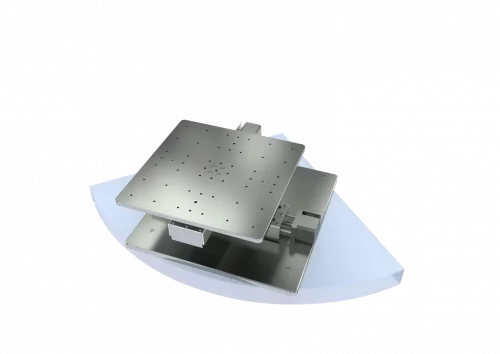

FM XY table

The automatically movable X/Y table enables the marking field to be enlarged in the X and Y directions

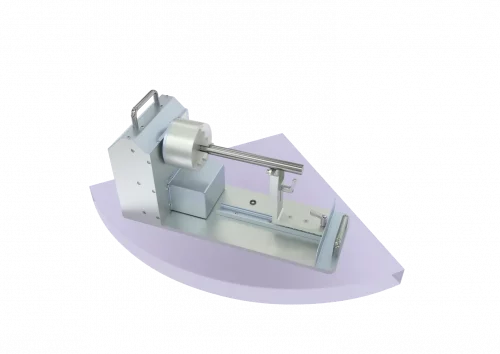

FM Rotary axis

The rotary axis function module (dividing head) is used for segmental labelling of the lateral surface on cylindrical components.

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

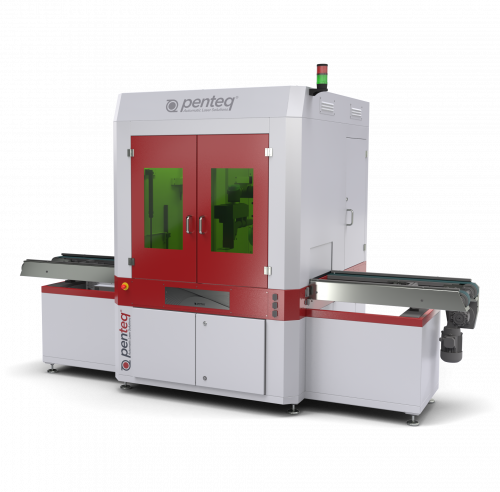

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling