Medical technology - UDI

Laser marking for durable and traceable labelling

UDI compliant - laser labelling on medical devices

Durable and clear labelling for the highest demands

Ultra Black Marking is a special type of laser marking in which ultra-short laser pulses from the Signolux® laser in the picosecond or femtosecond range are used to create an extremely dark, high-contrast and corrosion-resistant marking. The colour is created by selectively influencing the surface structure at nanometre level - without any conventional engraving or roughening.

This creates permanent markings with UDI codes and serial numbers.

Ultra Black Marking with UKP laser Signolux® in medical technology

The advantages of the laser lie in the wide range of applications and the outstanding labelling quality.

Permanent, high-contrast marking without damaging the material

Maximum precision and traceability are essential in medical technology.

The ultra-short pulse laser technology (USP) of the Signolux® laser enables an innovative process for permanent black marking - so-called Ultra Black Marking. This method ensures stable, legible markings on stainless steel, titanium and other medical materials - without any material removal or structural changes.

Penteq is a GS1 Solution Provider

As an official GS1 Solution Provider, Penteq supports companies in implementing global standards for labelling and traceability.

With our many years of experience in laser technology, we offer customised solutions for industrial direct marking - precise, durable and standard-compliant.

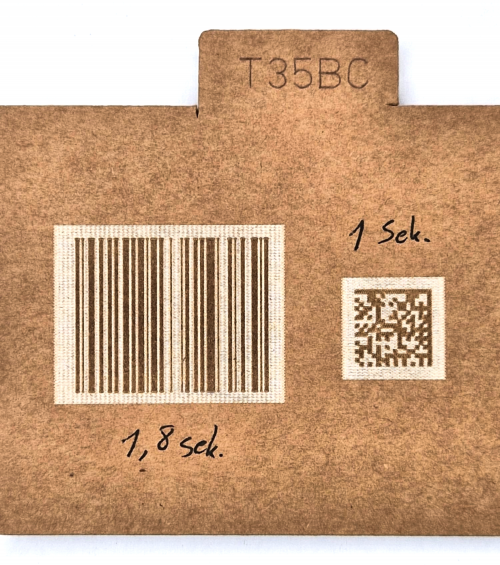

Our systems enable the integration of GS1-compliant codes such as DataMatrix or barcodes directly into your production processes.

What does UDI-compliant labelling mean?

Unique Device Identification (UDI) is a globally mandatory system for the unique identification of medical devices. The requirements are defined by the following regulations, among others EU-MDR 2017/745 (Europe) FDA UDI Rule (USA) GS1, HIBCC or ICCBBA as standard data formats.

A UDI consists of two parts: the device identifier (DI) and the production identifier (PI). The labelling must be machine-readable (e.g. DataMatrix code) and in plain text - permanently and clearly legible over the entire product life cycle. The Signolux® laser is therefore ideal for marking the UDI in accordance with the new EU Medical Device Regulation.

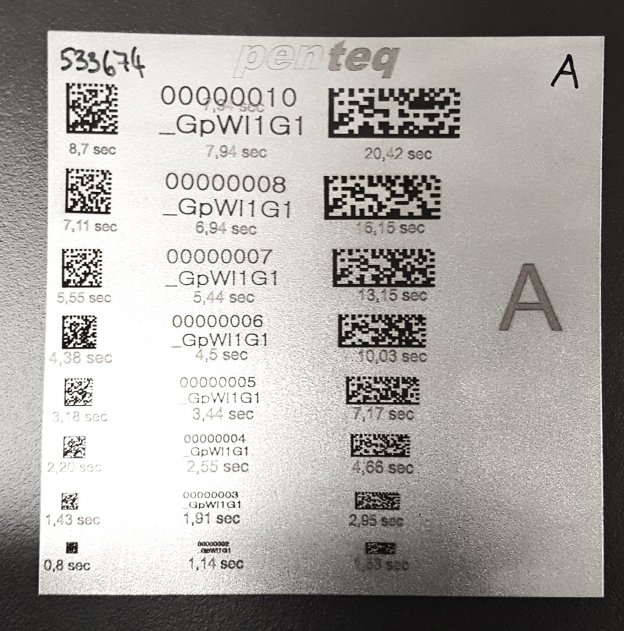

Example of the validation of a laser system:

As a medical company, would you like to ensure that your laser correctly applies data matrix codes to surgical instruments?

The following test steps should be carried out:

Is the code always legible?

Is the code permanent?

Is there a verification system in place?

Is every step documented?

Is the software protected against changes?

➡ We actively support your validation processes and guide you towards a standard-compliant process.

Validation in accordance with GMP and GAMP is a structured process that ensures that a system (e.g. a laser system for labelling) works reliably and reproducibly - especially in regulated industries such as pharmaceuticals, medical technology or biotechnology.

Why Signolux® laser labelling?

Laser marking with the Signolux® laser is the preferred method for medical products - especially for stainless steel and glass.

Thanks to the special physical properties of the laser, stainless steel can be marked with high contrast and durability without negatively changing its properties. Glass is labelled without introducing microcracks into the material structure, thus ensuring durability and the highest quality.

Tamper-proof & durable

The laser markings are abrasion-resistant, corrosion-resistant and suitable for sterilisation.

Contactless & gentle on materials

Ideal for sensitive components - without chemical additives or inks.

Highest precision & quality

Detailed engraving of logos, serial numbers, data matrix codes Nanostructured surfaces that scatter light to create a deep black effect.

Minimal heat exposure, which is particularly advantageous for heat-sensitive materials.

No oxide layers that could change or corrode over time

The advantages of laser labelling in medical technology

Areas of application

- Surgical instruments

- Implants and prostheses

- Endoscopic devices

- Diagnostic and laboratory technology

- Plastic housings for medical electronics

- Glass containers

Forgery-proof

- Tampering leaves visible traces

- Clearly identifiable through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high read reliability

Resistant

- Highly resistant to heat, abrasion and mechanical stresses

- Withstands sterilisation processes

- Suitable for establishing a traceability system

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

LG500 A Double shutter

Automatic loading system for large workpieces

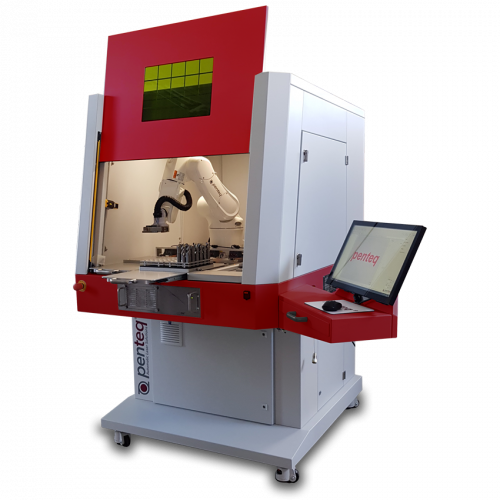

SG 500 RoboLaser

Flexibility through laser robots

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces