Glass + ceramics

High-precision, material-friendly engraving + labelling

Laser labelling & engraving of glass and ceramics

Precise. Durable. Contactless.

The laser marking and engraving of ceramics requires particular precision and experience, as these materials are among the hardest and most brittle materials. The right choice and suitable optical configuration of the laser system in combination with the process parameters specially determined for the respective application during application development guarantee optimum results, permanently.

Variety & quality

Glass and ceramics are among the most precious, but also the most sensitive materials in technology, design and industry. Our specialised laser marking processes enable high-precision, material-friendly engraving on almost all types of glass and ceramics - optionally also with Signolux ultra-short pulse laser technology (USP) for the highest demands.

We offer turnkey solutions for the production of large and very large quantities with automated systems.

Damage-free glass labelling

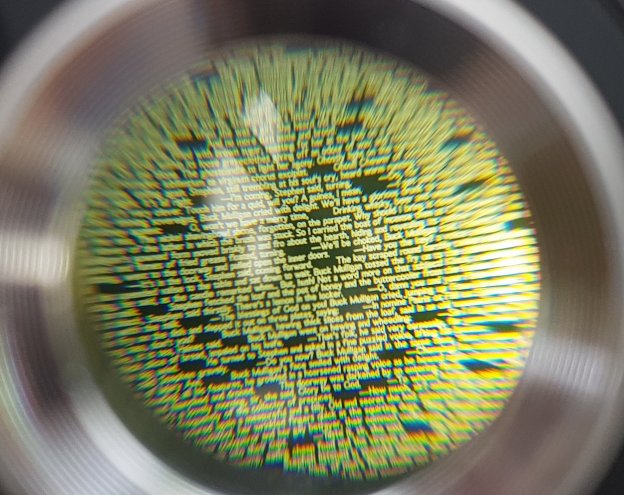

The laser marking of glass places high demands on precision and material protection. Due to its transparency and brittleness, conventional laser processes can easily lead to stress cracks, unwanted clouding or chipping. To avoid this, we rely on two highly specialised technologies. UV lasers and ultra-short pulse lasers (USP). The UV laser works with a wavelength of 355 nm and enables particularly fine, high-contrast markings on glass - for logos, codes or technical labelling, for example. Thanks to the high absorption in the ultraviolet range, glass can be modified locally without heat penetrating into deeper layers. This results in precise, smooth and permanent markings, ideal for applications in electronics, medical technology or design objects.

Glass labelling with UKP Signolux

The Signolux UKP laser is used for the highest demands. This technology generates ultra-short laser pulses that ablate the material by "cold ablation" - without contact, without thermal influences, without micro-fractures.

USP lasers enable micro lettering, filigree engravings and even structured effects on sapphire glass or technical glass - with maximum edge quality and without impairing the strength of the component.

Labelling and engraving ceramics

With modern laser technologies - in particular the Signolux ultra-short pulse laser (USP) and pulsed fibre lasers - permanent, high-resolution markings and engravings can be created on ceramic surfaces without thermally stressing or damaging the material. Depending on the application, the marking can be used for functional or design purposes, for example to refine housings, implants or precision components. The laser produces non-contact, abrasion-resistant markings that can be applied to small areas with high repeat accuracy. Signolux USP lasers deliver excellent results, particularly with glazed or high-density ceramic materials such as aluminium oxide (Al₂O₃), zirconium oxide (ZrO₂) or silicon nitride. They enable micro-engraving with high edge quality, without cracks or material flaking - a decisive advantage over mechanical processes.

The advantages of laser marking on glass and ceramics

Flexible and economical

- Labelling with logos, plain text, serial numbers and codes

- Individualisation

- No consumables such as labels or inks

Forgery-proof

- Tampering leaves visible traces

- Traceability of products through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high read reliability

- Fast

Resistant

- Highly resistant to heat, abrasion and chemicals

- Functional engravings with defined depth

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

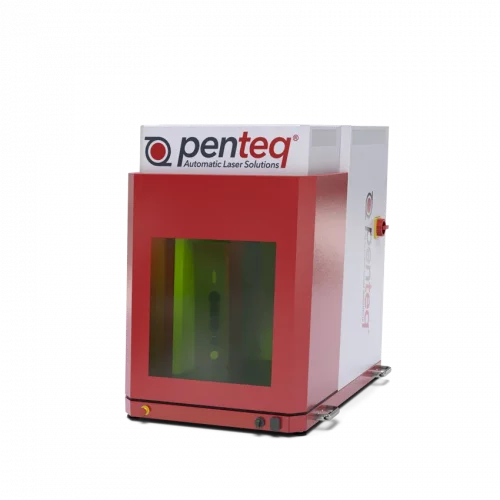

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

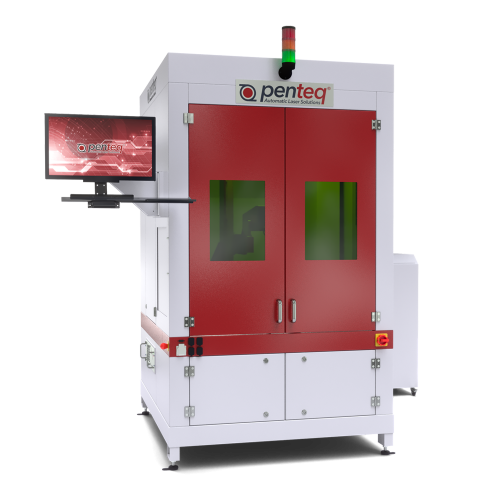

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

LG500 A Double shutter

Automatic loading system for large workpieces

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

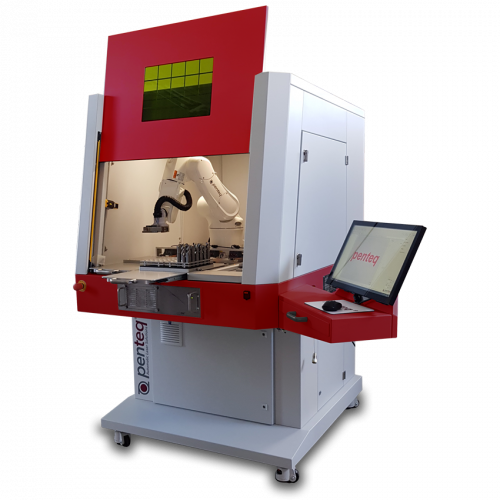

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

OEM Carbonline

CO₂ technology for versatile applications

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

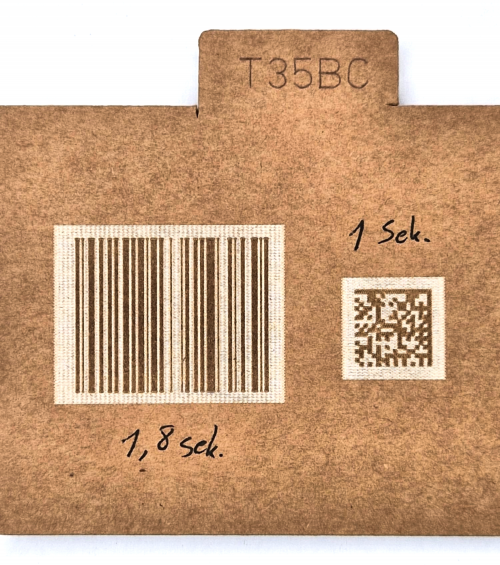

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Further applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments