Tool manufacturer

Penteq laser systems offer tool manufacturers maximum precision and efficiency. Their non-contact processing enables precise engraving, shortens production times and minimises tool wear.

Penteq in tool manufacture

Penteq laser systems impress tool manufacturers with their ability to mark tools with the utmost precision and attention to detail. Non-contact laser processing guarantees that every tool is labelled gently - from fine contours to precise dimensions. This results in long-lasting markings that impress even under demanding operating conditions. At the same time, the efficient machining processes enable shorter production times and reduce material wear, resulting in significant cost savings.

Applications

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

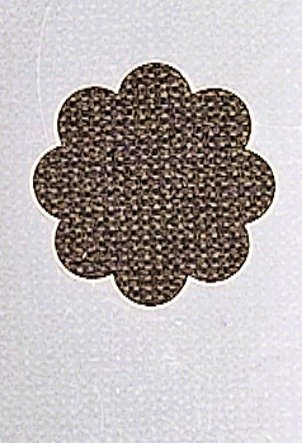

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

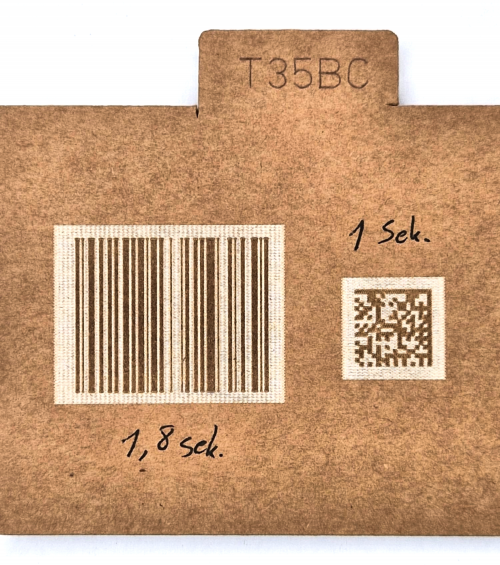

Cutting tools

Flexible and durable laser labelling

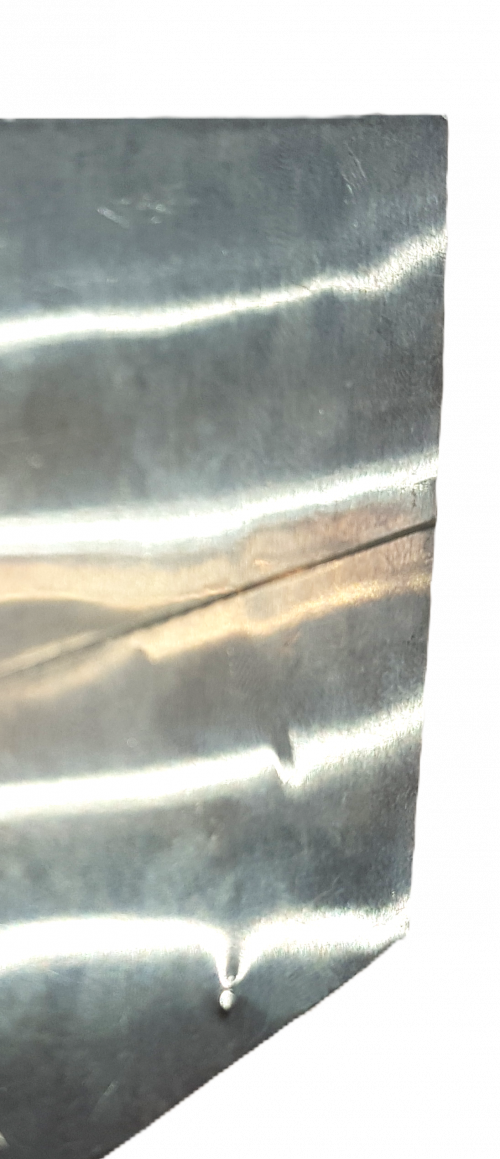

Dynamic Precision Welding

Maximum precision at maximum process speed

Spot welding

Precise. Fast. Contactless.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

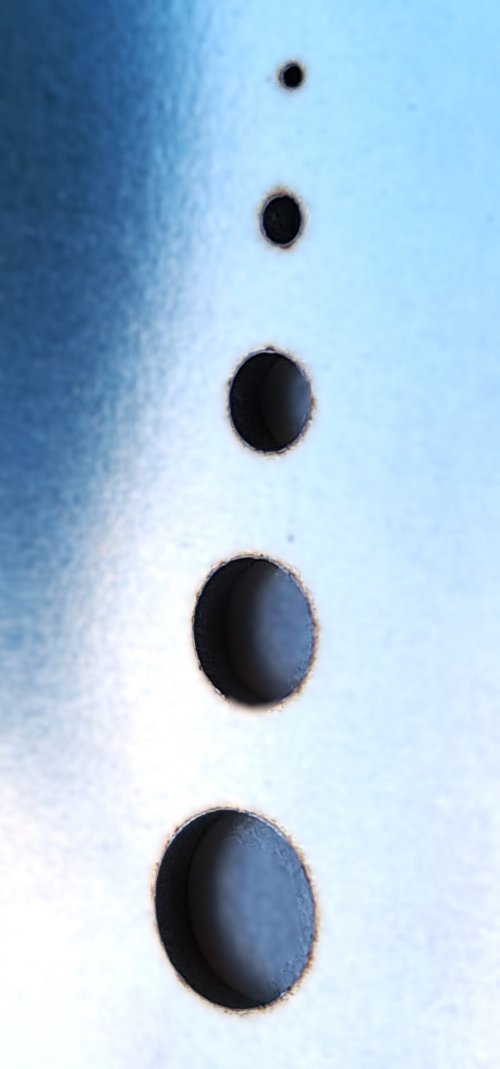

Perforating and punching

Precision laser perforation for demanding materials.

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Products

OEM fibreline

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

Smartlaser LG20

The intuitive system for professional results

Desktop Laser LG50

Simple, compact and reliable

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling