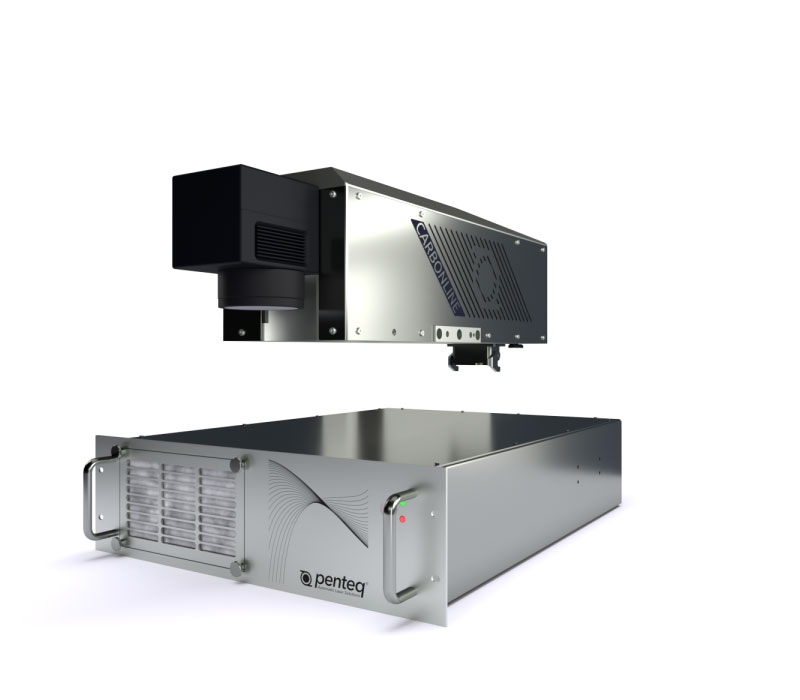

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

You can also visit the OEM Carbonline on our

High-precision CO₂ technology for efficient material processing

The OEM Carbonline series combines reliability and versatility in a powerful CO₂ system. With a wavelength of 9300 nm and a laser power of up to 120 W, it offers precise results when engraving, labelling and processing a wide range of materials such as polycarbonate (PC). The compact design enables easy integration into existing production systems, while the maintenance-friendly design ensures a high level of operational reliability.

CO₂ laser with a wavelength of 9300 nm (9.3 µm)

The lasers in the Carbonline series with a wavelength of 9.3 µm differ significantly from the "classic" CO₂ laser wavelength of 10,600 nm and offer special advantages for certain industrial applications.

Many plastics (especially PET, polycarbonate, PVC, etc.) absorb the 9.3 µm radiation much better than 10.6 µm, resulting in cleaner cuts, less material distortion, fewer smear marks and higher marking quality. Particularly relevant for film cutting and marking in the packaging industry and medical technology . The high absorption in thin films (e.g. PET) allows precise cuts without thermal damage to surrounding areas.

Medical packaging & blister packs

For precise laser marking on medical packaging & blister packs on transparent plastic films where clarity and durability are essential.

Fine engraving and structuring of printed circuit board materials (e.g. flexible circuits) in the electronics industry.

| Feature | 9.3µm CO² laser | 10.6µm CO² laser |

| Wavelength | 9300 nm | 10650nm |

| Typical application | Standard for organic materials | Specialised for certain plastics |

| Absorption in plastics | for PET, PC higher | Good in many materials such as PE, PP, wood, paper |

| Thermal load | Lower for the above materials | higher |

| Cut quality (for films) | Better and cleaner | Can lead to smoke development |

| Heat-affected zone (HAZ) | Local | Extended |

Powerful CO₂ laser sources

The OEM Carbonline is available in three power levels - 30W, 60W and 120W - and therefore offers an ideal solution for different processing requirements.

Compact integration

The space-saving 19″ format contains the power supply unit and industrial PC and can be easily integrated into existing production lines.

Flexible configuration options

With options such as SmartAdjust, positioning laser and 3D function, the system can be perfectly customised to individual production processes.

User-friendly control

Intuitive software and standard interfaces such as Profinet ensure simple operation and smooth integration. Optional control of up to 6 external axes from the Pensoft interface enables seamless integration of automation components.

OEM Carbonline 9.3µm - the powerful CO₂ laser

Discover the advantages of the PENTEQ® OEM Carbonline series. Contact us to optimise your manufacturing processes with this durable and powerful integration kit.

| Output power | 10 watts |

| Standard field of work | 110 x 110 mm |

| Field of work Optional | 160 x 160 mm |

| Wavelength | 9300 nm |

| Working distance approx. | 190 mm |

| Power consumption | 650 W |

| Weight approx. (head and supply unit) | 45 kg |

| Output power | 30 watts |

| Standard field of work | 110 x 110 mm |

| Field of work Optional | 160 x 160 mm |

| Wavelength | 9300 nm |

| Working distance approx. | 190 mm |

| Power consumption | 800 W |

| Weight approx. (head and supply unit) | 45 kg |

| Output power | 60 watts |

| Standard field of work | 110 x 110 mm |

| Fields of work Optional | 160 x 160 mm |

| Wavelength | 9300 nm |

| Working distance approx. | 190 mm |

| Power consumption | 1200 W |

| Weight approx. (head and supply unit) | 55 kg |

| Output power | 120 watts |

| Standard field of work | 110 x 110 mm |

| Fields of work Optional | 160 x 160 mm |

| Wavelength | 9300 nm |

| Working distance approx. | 190 mm |

| Power consumption | 1600 W |

| Weight approx. (head and supply unit) | 55 kg |

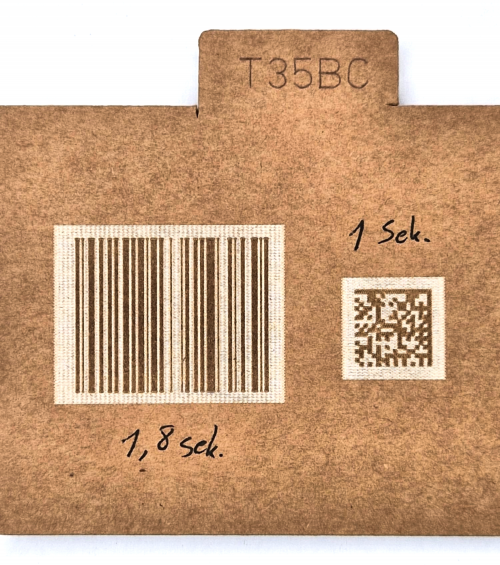

Marking on the Fly (MOF)

Marking on the fly is the contactless labelling or engraving of products while they are moving on a conveyor belt - in other words, "on the move". The laser system synchronises its marking with the speed of the transported object so that texts, codes or logos are applied precisely at the desired position without interrupting the production flow. MOF is primarily used in high-speed lines, for example in the food, beverage, pharmaceutical and packaging industries, and enables efficient, permanent and precise product labelling without downtime.

Matching products

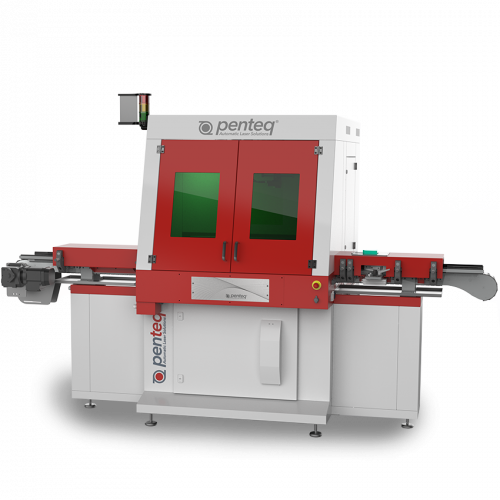

Rotary transfer laser system

Automatic with flexible workpiece holders

Laser workstation LG 200

Modularity as a pioneering concept

Rotary table laser LG200 RT

For maximum production speed

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

Laser system with pocket wheel

Automatic laser system with optimised material flow

LG500 A Double shutter

Automatic loading system for large workpieces

Applications

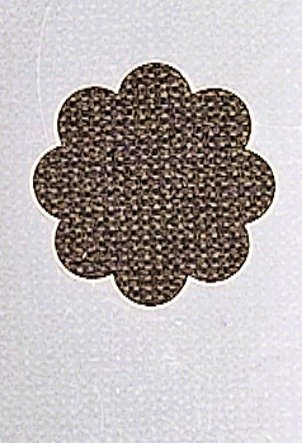

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling