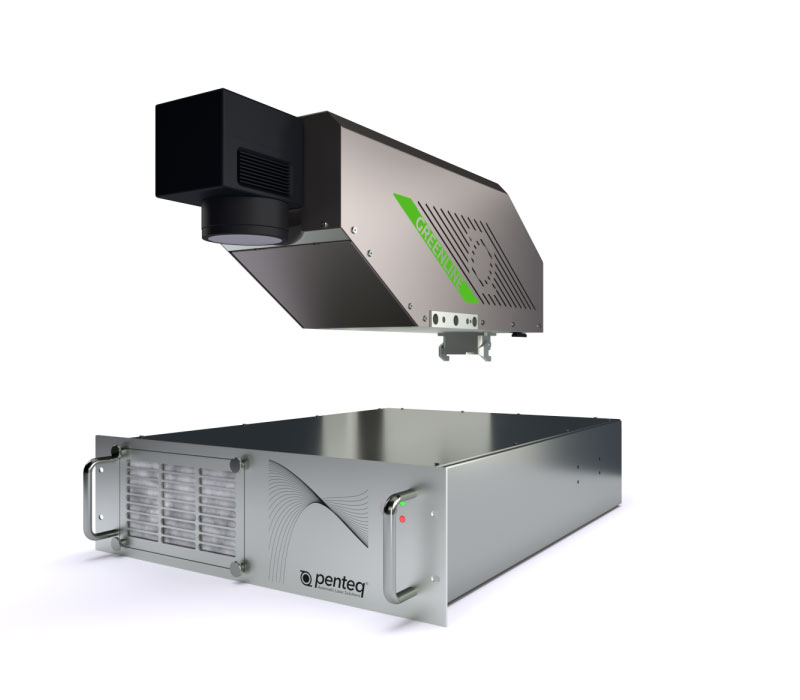

OEM Greenline (Green Laser)

Precision laser for sensitive material processing

You can also visit the OEM Greenline on our

State-of-the-art DPSS technology for the most precise results

The air-cooled OEM Greenline G5 integration kit is characterised by its exceptional beam quality and short pulse duration, which enables precise material processing with a minimal heat-affected zone. With a wavelength of 532 nm and an output power of 5 watts, it offers consistent results even in demanding applications such as engraving, cutting or cleaning.

Thanks to its compact design and flexible optical fibre (3,000 mm long), the system integrates seamlessly into existing production environments. The high pulse-to-pulse stability makes it the ideal choice for manufacturing processes that require maximum precision and repeatability.

Powerful beam source

The DPSS Nd:YV04 laser delivers precise and constant results with a frequency of 1-300 kHz. These properties make it ideal for applications where maximum accuracy and reliability are required.

Space-saving design

The compact 19″ format includes an integrated supply unit and an industrial PC. This allows the Greenline G5 integration kit to be seamlessly integrated into existing production lines.

Optional extensions

Functions such as SmartAdjust, a positioning laser, a 3D function and laser fume extraction are available for maximum flexibility. These options facilitate customisation to specific requirements.

User-friendly control

Intuitive software allows easy operation and customisation to individual requirements. This saves time during set-up and increases efficiency in day-to-day operations.

Outstanding stability

Thanks to the air-cooled technology, the system offers an exceptionally long service life and high operational reliability, even under 24/7 conditions.

OEM Greenline G5 - Your solution for precise laser processing

Talk to our experts and find out how the Greenline G5 integration kit can optimise your production. We will be happy to advise you and work with you to develop the best solution for your production requirements.

| Power (watts) | 5 |

| Laser type | GreenLine |

| Wavelengths | 532 nm |

| Weight: Laser / supply unit | approx. 10 kg / approx. 30 kg |

| Fibre length | 4 m |

| Cooling | Thermo-electric, integrated cooling |

| Supply voltage | 230 V 50 Hz |

| Power consumption | approx. 900 W |

| Electrical interfaces | 2 x USB, 1 x Ethernet |

| Software interfaces | TCP/IP (standard), Profinet, OPC-UA, Ethercat. Others possible after clarification |

| Ambient temperature | +15 to +35°C |

| Rel. humidity | 10% to 80% (non-condensing) |

| IP protection class | IP 54 |

| Determined service life | Typically over 20,000 hours |

| Software | PenSoft Editor |

| Input | Full HD monitor with mouse & keyboard |

| Operating system | Windows 11 |

| Laser class | Laser class 4 |

| Possible marking fields | 110 x 110 mm (focus distance approx. 150 mm)Others on request |

Matching products

Rotary transfer laser system

Automatic with flexible workpiece holders

Laser workstation LG 200

Modularity as a pioneering concept

Rotary table laser LG200 RT

For maximum production speed

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

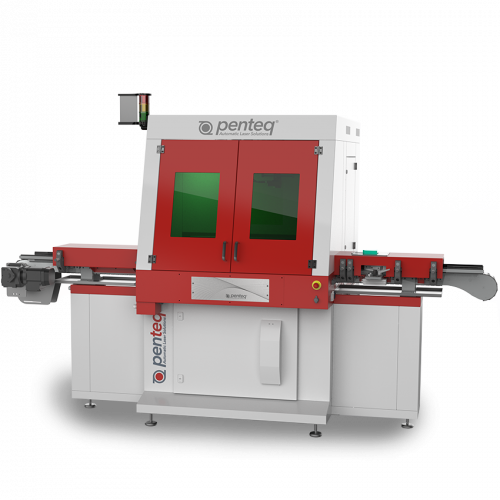

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser system with pocket wheel

Automatic laser system with optimised material flow

LG500 A Double shutter

Automatic loading system for large workpieces