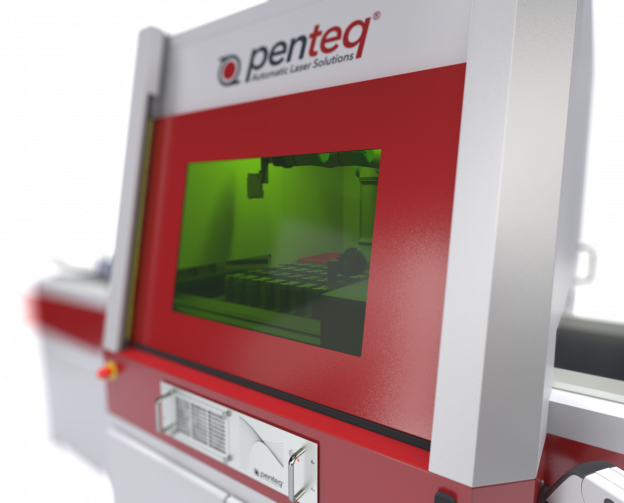

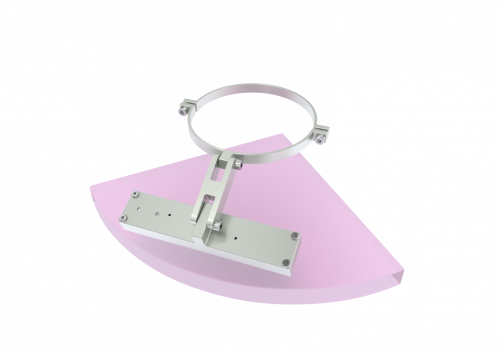

LG500 A Double shutter

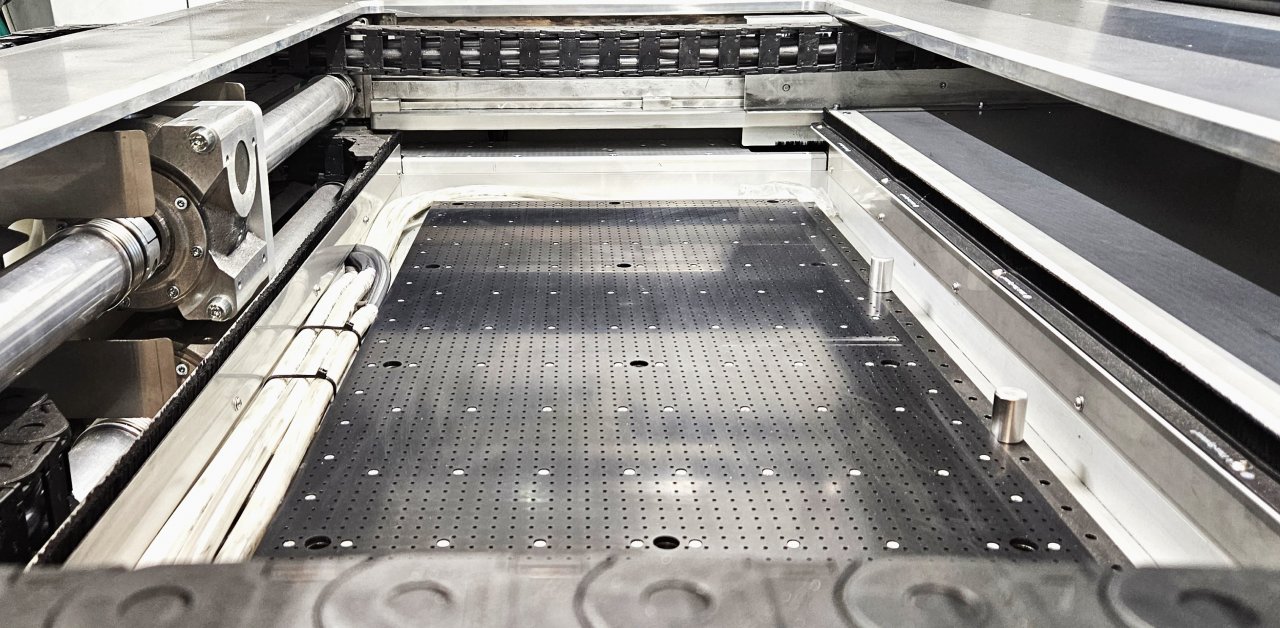

Automatic loading system for large workpieces

Flexible and efficient

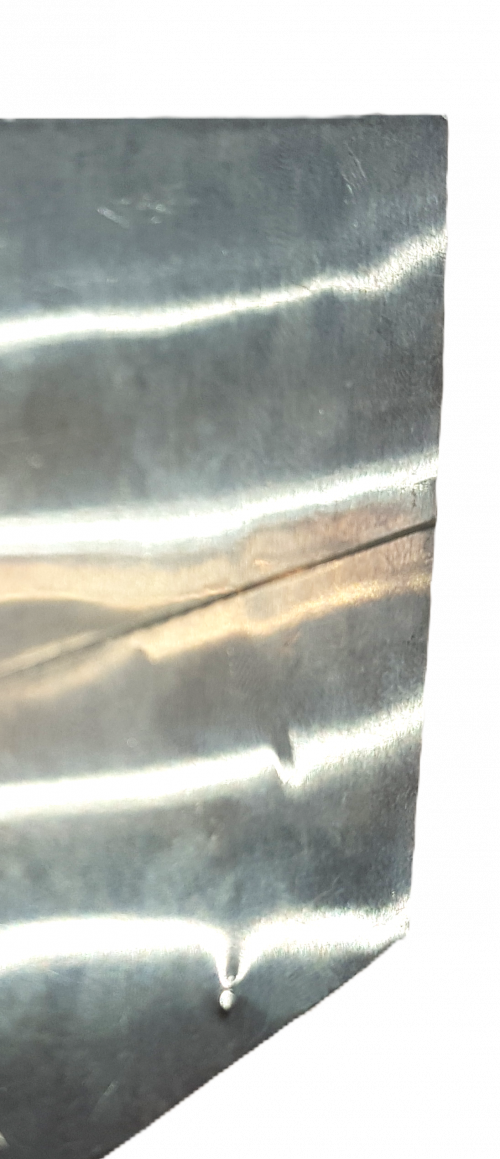

Large-area processing of workpieces made of aluminium, stainless steel, steel, brass, carbide and plastics with high surface performance. Ideal for surface processing such as laser cleaning and laser structuring of panels. The workpieces can be easily picked up via vacuum tables or clamping devices. An integrated stop system ensures accurate processing. All components such as the laser supply unit, industrial PC and laser fume extraction system, as well as any water cooler required for high laser power, are integrated into the system.

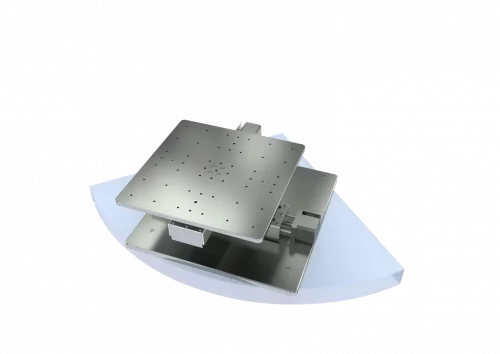

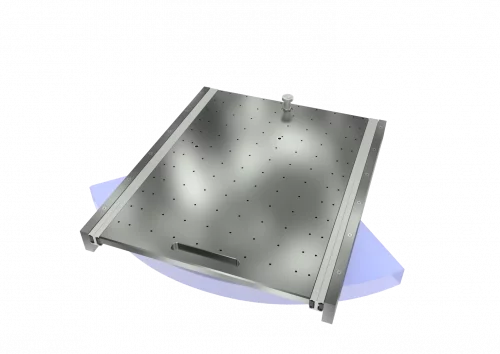

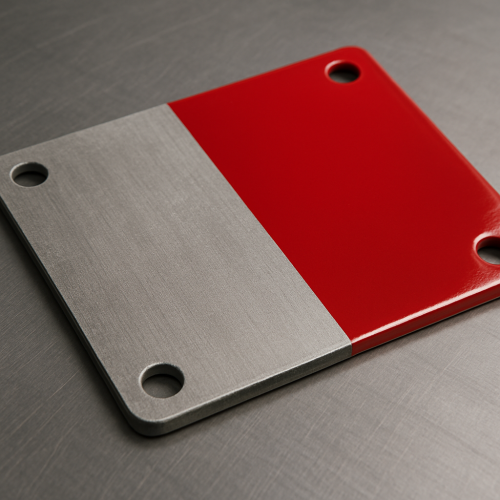

Various workpiece holders

Customised fixtures such as vacuum clamping plates or magnetic clamping plates can be used to feed a wide variety of workpieces. These can be equipped with various stop systems for easy positioning. Alternatively, position correction in X, Y and rotation is available using a camera. The simple creation of a wide variety of products enables a comprehensive layout catalogue to be set up quickly in the laser system.

Integrable vision systems

Our laser systems benefit significantly from integrable vision systems that enable precise and reliable quality control. These vision systems are specifically designed to inspect various product properties and ensure that they meet the given specifications.

Some of the typical applications include:

Colour inspection: Vision systems can detect colour deviations and check whether the colour coding or colour quality of a product meets the requirements.

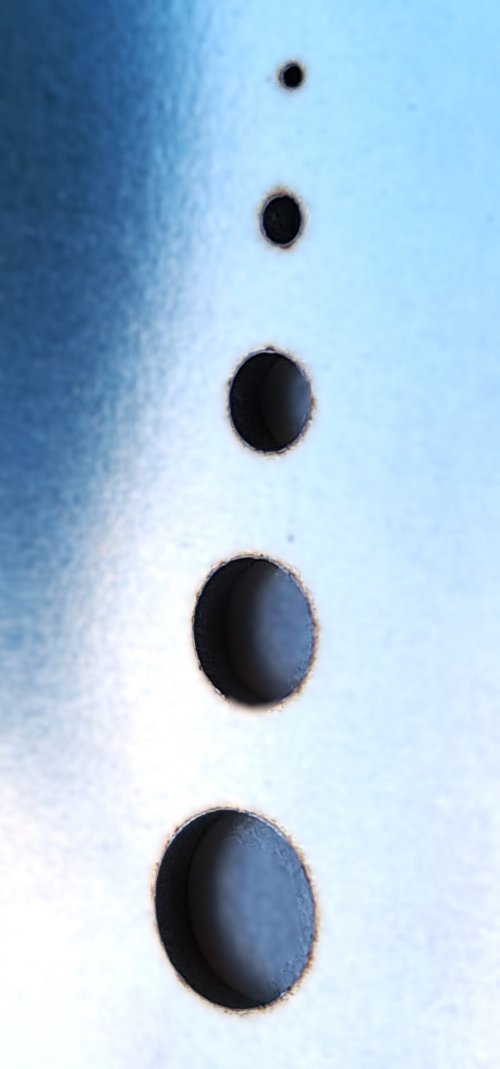

Recess presence inspection: Check that mechanical recesses or cut-outs are correctly placed and in the correct positions.

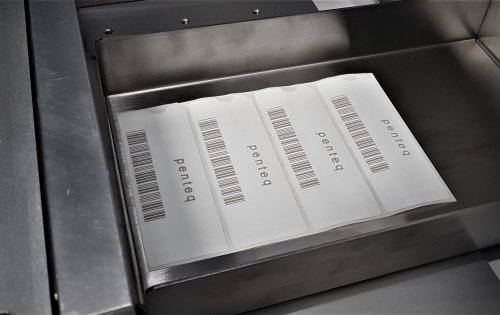

Code inspection: Laser systems can apply barcodes, QR codes or other markings to products, and the vision systems ensure that these codes are correct and legible.

Dimensional and geometric inspection: The systems can analyse the dimensions and geometry of a product in order to detect production errors at an early stage.

The integration of vision systems into laser systems offers several advantages:

Greater efficiency: automated inspection processes save time and reduce manual effort.

Improved quality assurance: Even the smallest deviations are detected immediately, minimising rework and complaints.

Data analysis and traceability: The systems document and save inspection results, enabling seamless tracking and analysis.

Thanks to the flexibility of modern vision systems, they can be customised to meet specific production requirements. This makes them an indispensable component of laser systems in various industries, from electronics manufacturing to the automotive industry.

Reliability and efficiency for maximum throughput

The machine is designed for many years of industrial use. A machine frame in welded steel construction and the powder-coated sheet steel panelling ensure durability. Dynamic drives and precise guides ensure fast and accurate positioning of the laser head. A specially developed concept for the reliable removal of particle flows, including a balanced air exchange, ensures shadow-free processing results.

Continuous further development for your needs

Our expertise enables us to provide practical solutions for various applications in the high-power laser sector. The possibilities range from laser cleaning to surface structuring and engraving. In our extensively equipped laser laboratory, we develop applications that are customised to your requirements.

Innovative double store concept

The use of automatic double loading enables workpieces to be loaded and unloaded in parallel with the process time. While the laser process is running inside the system, finished workpieces can be removed outside and new workpieces can be prepared. This minimises unproductive downtimes, optimises the material flow and ensures maximum throughput with high process reliability and user-friendliness.

Fast automatic door

The automatic door at the front is equipped with solid guides for a long service life. The electric drive ensures smooth and quiet operation despite the rapid movements.

The door design offers a large opening for convenient loading and unloading, even when handling bulky workpieces. An integrated, large laser safety window enables visual process monitoring.

Maximum security

An integrated light curtain reliably protects the operator from unwanted access during the table movement of the laser system and thus makes a decisive contribution to work safety, while at the same time ensuring smooth and optimised system operation.

Optimum operability

The screen, keyboard and mouse are mounted on an ergonomically height and tilt-adjustable, solid swivel arm. It is controlled and operated using PenSoft software specially developed for laser processing, which is easy to use after a brief introduction.

Layouts are created using an intuitive editor, which offers all the usual options for creating a perfectly customised layout.

Adjustable machine feet

Thanks to the adjustable machine feet in combination with a particularly solid and robust design, the system can be lifted and positioned easily and safely using a forklift if required. This enables flexible integration into different production environments and quick relocation of the machine without compromising stability, precision or process reliability. The height adjustment of the machine feet also ensures that the system can be precisely aligned to ensure optimum working conditions and consistently high production quality.

Challenge us

As a high-tech provider in the field of laser surface treatment, your success and the optimisation of your processes are particularly important to us. Do you have specific requirements? Let us know your needs and we will offer you customised solutions.

Benefit from the advantages of the double oven laser system and rely on Penteq as your expert for innovative production solutions. Our motto is: "Show us your requirements and we will show you our possibilities!"

| Dimensions (without conveyor) | 2240 x 1100 x 3100 mm (LxWxH) |

| Working area per workpiece carrier | 400 x 600 mm |

| Working area for manual assembly | 150 x 150 mm depending on optical configuration |

| Services | 3-3000 Watt |

| Weight of the system | 520 kg (depending on version) |

- DMC Camera

- Focus finder

Software

- PMS - Penteq Marking Software

- Penteq App Development

Accessories

- DMC camera - VisionSystem Verifier

- PSA (Penteq Smart Adjust)

- Pilot laser

- Laser fume extraction

- Foot switch

- Monitor on swivel arm

- Hand scanner for codes

- touch screen

- Bad parts box

- 3-stage status light

- Fiberline F20

- Fiberline F30

- Fiberline F50

- Fiberline F100

- Fiberline F120

- Fiberline F150 Q-CW

- Fiberline F300 Q-CW

- Fiberline F500

- Fiberline F1000

- Fiberline F2000

- Carbonline C30

- Carbonline C60

- Carbonline C120

- UV Line

- Greenline

Matching products

FM XY table

The automatically movable X/Y table enables the marking field to be enlarged in the X and Y directions

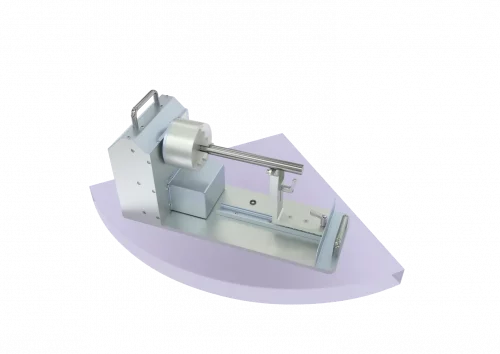

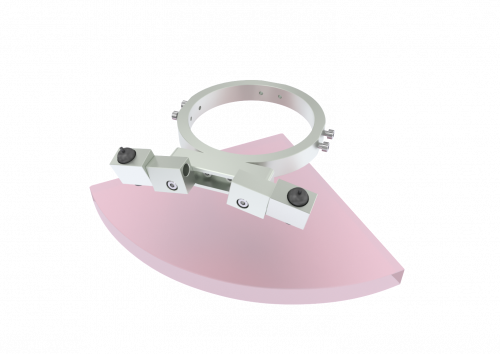

FM Rotary axis

The rotary axis function module (dividing head) is used for segmental labelling of the lateral surface on cylindrical components.

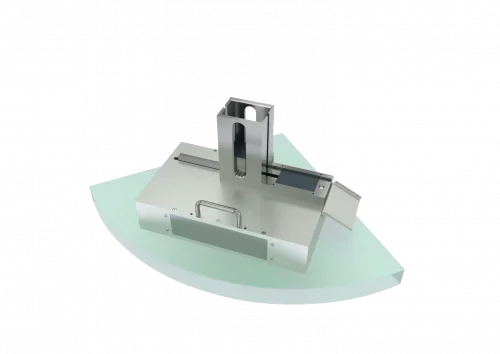

FM Extendable table

The door can be opened completely and the support table pulled out towards the operator for adjustment and set-up work, as well as for picking up large or heavy parts.

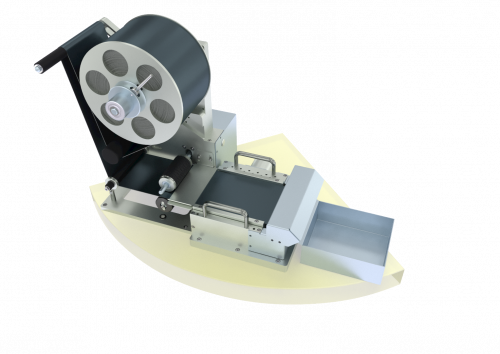

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

PenSoft Control

Easy-to-use interface for laser applications

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

OEM Greenline

Precision laser for sensitive material processing

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

OEM fibreline high power

Ready-to-install laser for numerous applications

Applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Cutting tools

Flexible and durable laser labelling

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Watch components

Precisely joining what belongs together

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling