Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Cutting off plastic sprues

Precise. Contactless. Efficient.

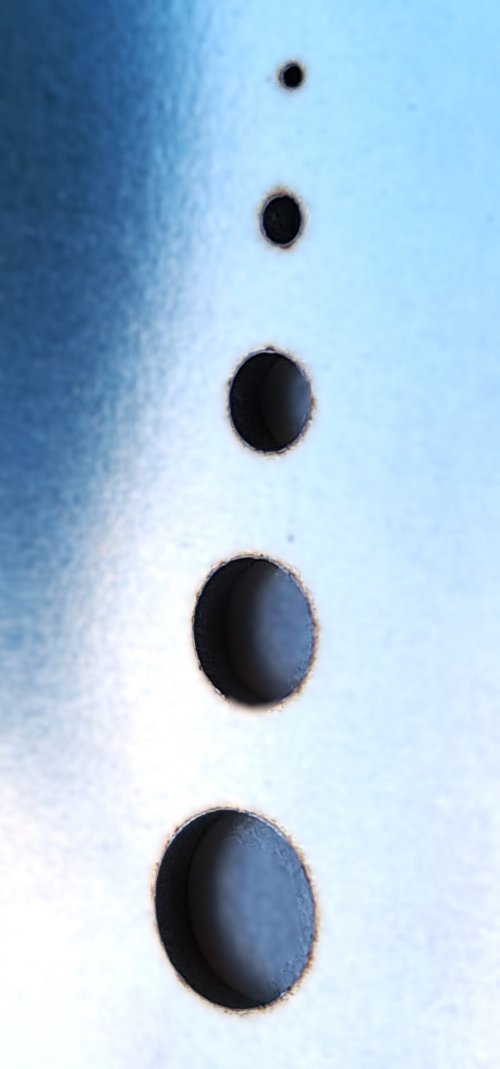

The sprue is the area of a plastic part through which the melt enters the mould during the injection moulding process. After solidification, this connecting web is separated. It can vary depending on the size and geometry of the moulded part and the injection process (spot, film or cold runner gate).

What is laser cutting of plastic sprues?

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding. Using high-precision laser technology, the sprues are removed cleanly and in a material-saving manner - without mechanical stress on the workpiece.

Why laser technology instead of mechanical separation?

Conventional methods such as punching or cutting reach their limits with complex geometries or sensitive materials. Laser-based systems offer decisive advantages here:

- Non-contact: No tool wear, no mechanical deformation

- Maximum precision: Ideal for intricate structures and tight tolerances

- Clean cutting edges: Hardly any reworking necessary

- Can be automated: Can be integrated into existing production lines

Typical areas of application

Laser cutting is particularly suitable for:

- Medical technology - sterile processing without residues

- Automotive industry - high repeat accuracy for series production

- Electronic components - finest details without microcracks

- Consumer goods industry - clean surfaces without burrs

Automation & inline capability

A major advantage is that laser cutting can be easily integrated into automated production lines - inline directly after injection moulding or in separate post-processing cells.

- Robot-assisted feeding

- Cycle time-optimised processing

- Interfaces to MES/ERP systems

Comparison of sprue cutting processes

| Criterion | Laser cutting | Mechanical (knife/punch) | Thermal (hot cutter) | Manual (pliers, knife) |

|---|---|---|---|---|

| Non-contact | ✔️ Yes | ❌ No | ❌ No | ❌ No |

| Cutting quality | ⭐⭐⭐⭐ Very high | ⭐⭐ Medium | ⭐ Low | ⭐ Low |

| Burr formation | ❌ None or minimal | ✔️ Possible | ✔️ Clear | ✔️ Clear |

| Material deformation | ❌ None | ✔️ Possible (especially for thin parts) | ✔️ High (heat distortion) | ✔️ Possible |

| Repeatability | ⭐⭐⭐⭐ High | ⭐⭐ Medium | ⭐ Low | ❌ None |

| Automation capability | ✔️ Very good | ✔️ Possible, but limited | ❌ Difficult | ❌ Not possible |

| Cutting speed | ⭐⭐⭐ Fast | ⭐⭐⭐⭐ Very fast | ⭐⭐ Medium | ⭐ Slowly |

| Tool wear | ❌ None | ✔️ High (cutting, punching) | ✔️ High (heating elements) | ✔️ High |

| Costs per part (long-term) | ⭐⭐ Medium | ⭐⭐ Medium | ⭐ Low short-term, high long-term | Low for small series |

| Investment costs | 🡹 High (system, laser source) | 🡹 Means (tools + mechanics) | 🡻 Low | 🡻 Very low |

| Flexibility with geometries | ⭐⭐⭐⭐ Very high (also 3D) | ⭐⭐ Medium (depending on mould shape) | ⭐ Low | ⭐⭐ Medium |

| Post-processing necessary? | ❌ Mostly not | ✔️ Frequent | ✔️ Yes | ✔️ Yes |

| Suitable for series production | ✔️ Optimal | ✔️ Restricted | ❌ No | ❌ No |

Frequently asked questions (FAQ)

Which materials can be cut with a laser?

All common thermoplastics such as ABS, PC, PP, PE, POM and fibre-reinforced plastics.

How fast is the process?

Depending on component geometry and material: a few seconds per interface - ideal for short cycle times in mass production.

Is post-processing necessary?

Not in most cases. The edges are smooth and clean, without mechanical damage.

Our laser technology in detail

We use modern CO₂, fibre or UV lasers - depending on the requirements and the material to be separated. Our lasers can be optionally equipped with vision systems and offer:

- Camera-supported component recognition

- Automatic focussing

- Dynamic cutting according to component contour

- Integrated special laser fume extraction

Get advice now

Benefit from our experience in laser material processing. Our experts will support you in selecting the right technology for your application.

Suitable products

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

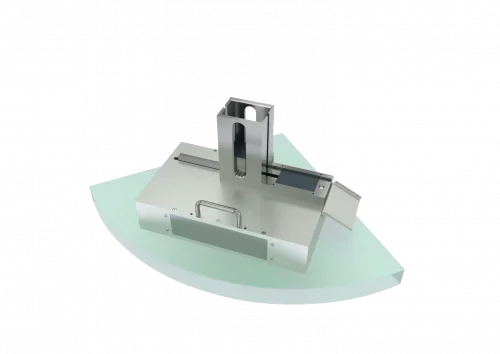

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Smartlaser LG20

The intuitive system for professional results

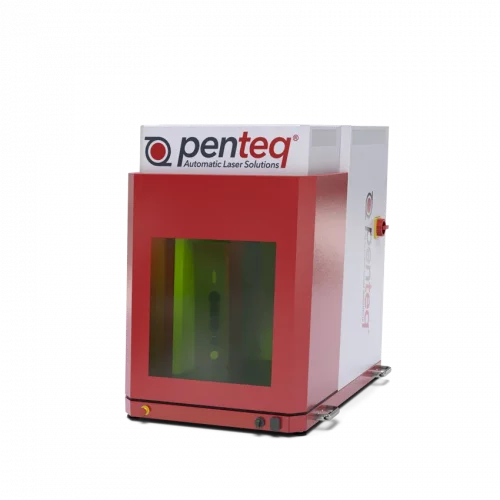

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

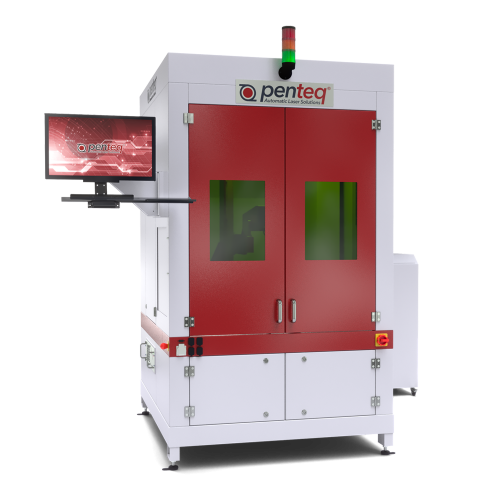

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

OEM Carbonline

CO₂ technology for versatile applications

LG500 A Double shutter

Automatic loading system for large workpieces

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

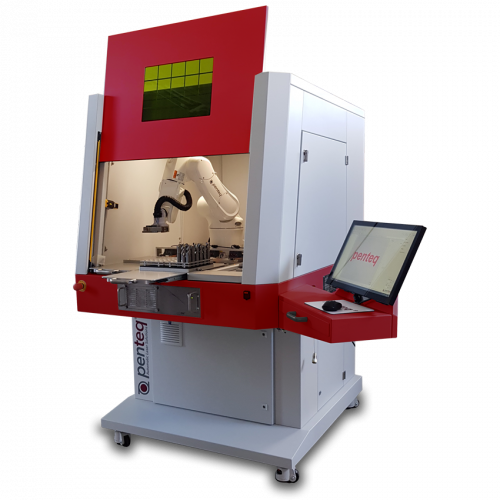

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments