Laser labels

Flexible in shape, size and content for permanent traceability

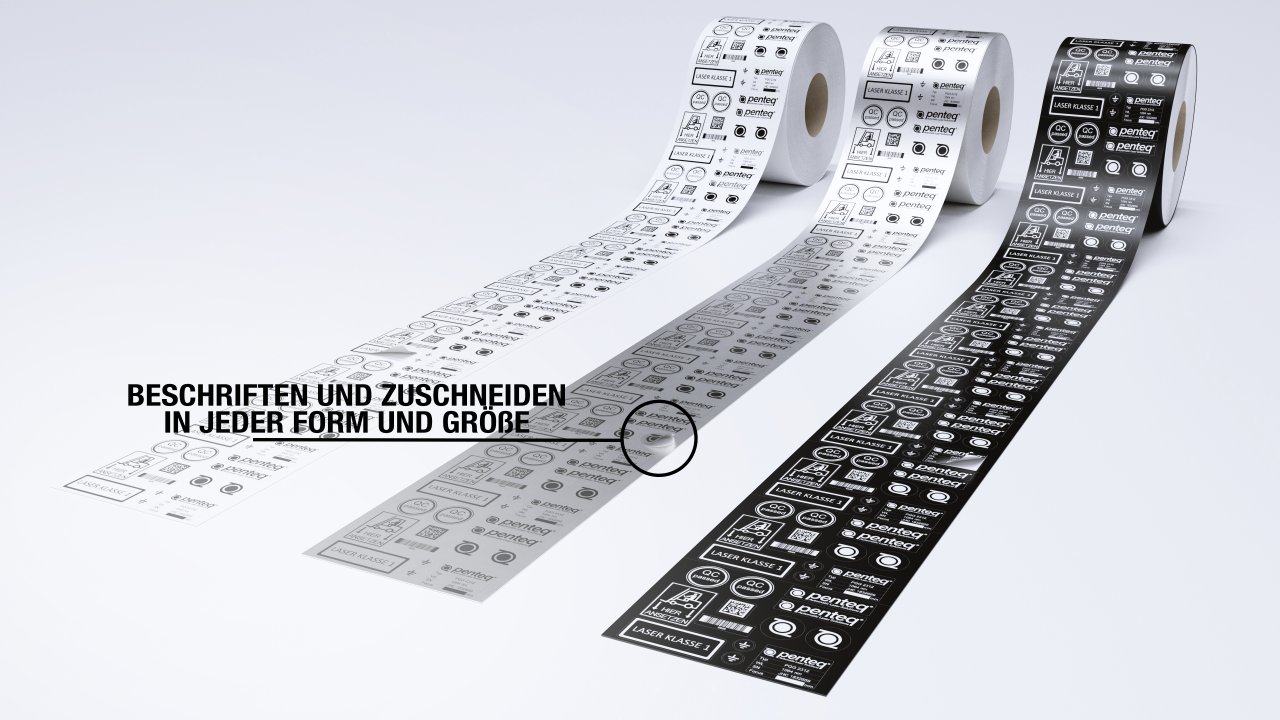

Flexible cutting and labelling of laser labels

Precision meets flexibility: your solution for sophisticated labelling

Flexibility & quality

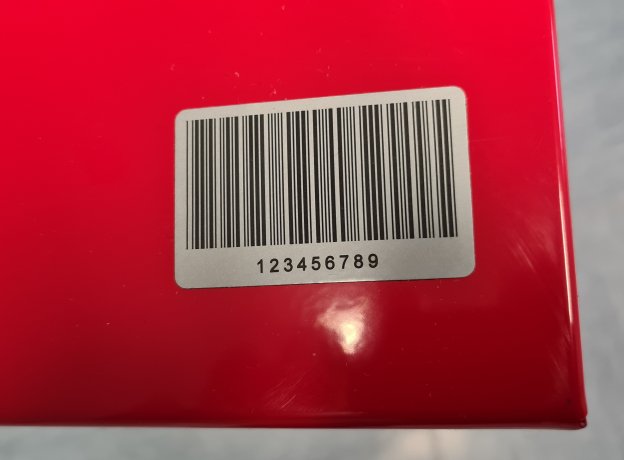

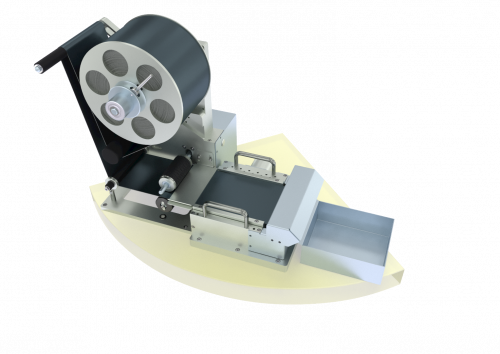

Laser markable labels are a very interesting option for marking workpieces that are not to be labelled directly. They are also suitable for simple labelling of heavy and large components. The labels are laser-marked and cut from the roll in a single operation. This enables the production of any desired label size and shape up to 120 x 120 mm using a laser foil.

With our laser systems, you can cut labels precisely in a single work step and label them individually at the same time. Whether serial numbers, barcodes, logos or variable data. Labelling with laser foil is more efficient and adaptable than ever.

Resistant & durable

Highest labelling quality: Permanent, high-contrast laser marking for text, 2D codes, graphics or serial numbers.

Real-time individualisation: Ideal for on-demand production, UDI marking or track & trace applications. The laser labels fulfil all legal standards and can be used as a tamper-proof identification solution throughout the entire life cycle of a product. They are particularly resistant and durable against chemicals, solvents, abrasion, extreme temperatures and weather conditions.

Suitable for traceability

The laser labels are also suitable as data carriers for traceability (barcode, data matrix code, QR code) and for intelligent process control and cannot be removed non-destructively.

With our laser systems, you can cut labels precisely and label them individually in a single work step - without any tool changes, punching or lead time. Whether serial numbers, barcodes, logos or variable data: We make your labelling more efficient and adaptable than ever.

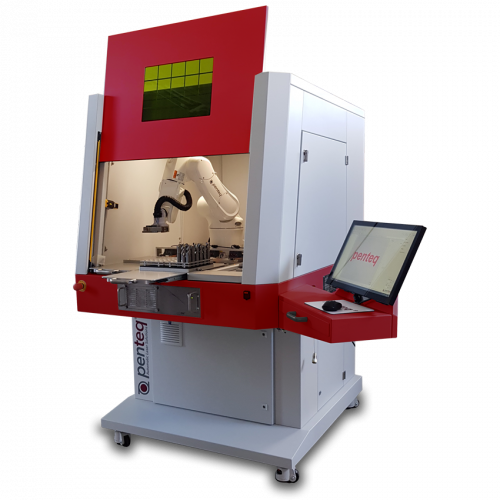

See how our users benefit

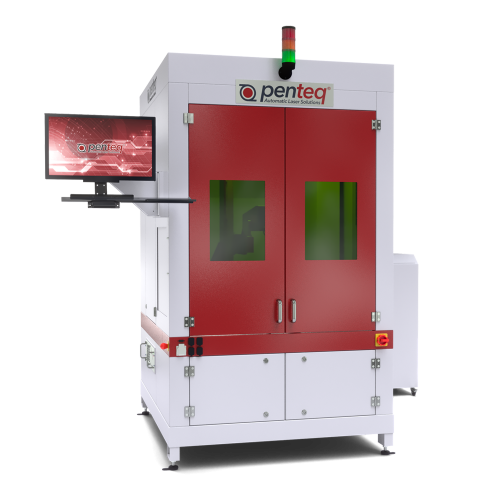

The HABAU GROUP is an international full-service provider for almost all areas of the construction industry. As one of the leading construction groups in Austria, HABAU is also a pioneer in the field of digitalisation. Penteq was selected as a partner for the implementation of an industrial laser system for labelling equipment with Data Matrix codes for digital recording. The modular system concept of the LG200 laser system enables the direct laser labelling of components as well as the automated production of laser labels and laser-engraved type plates by means of function modules that can be easily exchanged without tools. The software was integrated into HABAU's IT system via standardised interfaces and a customer-specific, configurable and modular software solution from Penteq.

Laser foils vs. thermal transfer labels

The smart alternative to classic labelling.

Whether in medical technology, electronics production or mechanical engineering - if you need durable, flexible and high-quality labelling, laser foils are the first choice.

| Criterion | Laser foil (e.g. Tesa®) | Thermal transfer label |

|---|---|---|

| Durability / legibility | ⭐⭐⭐⭐ Very high | ⭐⭐⭐ Medium to high (depending on band) |

| Resilience | ⭐⭐⭐⭐ Chemistry, heat, abrasion | ⭐⭐ Limited depending on band & label |

| Print quality (barcode etc.) | ⭐⭐⭐⭐ Excellent (laser precision) | ⭐⭐ Good, but material-dependent |

| Shape flexibility | ✔️ Freeform possible | ❌ Standard formats or die-cutting |

| Tool costs | ✔️ None | ⚠️ Possible punching costs |

| Tamper protection | ✔️ Possible (Void, Destructive) | ⚠️ Restricted |

| Printing material required | ❌ No | ✔️ Yes (colour ribbons) |

| Maintenance & consumption | ✔️ Low | ❌ Higher (print head, ribbon, cleaning) |

| Automation capability | ⭐⭐⭐⭐ High | ⭐ Possible, but more complex |

| Investment / unit costs | 🡹 Higher purchase price | 🡻 More favourable for bulk labels |

Advantages of laser labels at a glance:

Flexible and economical

- Flexible layout design: labelling with logos, plain text, serial numbers and codes

- Efficient: No need to stock prefabricated signs:

Just-in-time production on the line as required

- No minimum quantities per label variant

- No surplus production (waste of material)

- Low procurement and administration costs - Suitable for end-to-end product traceability

Forgery-proof

- Tampering leaves visible traces

- Clearly identifiable through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high readability

- Can be labelled quickly: by engraving or colour change

Resistant

- Highly resistant to heat, abrasion and chemicals

- Flexible mounting options

Would you like to introduce laser labelling in your production?

We support you with software integration and produce material samples according to your specifications!

Suitable products

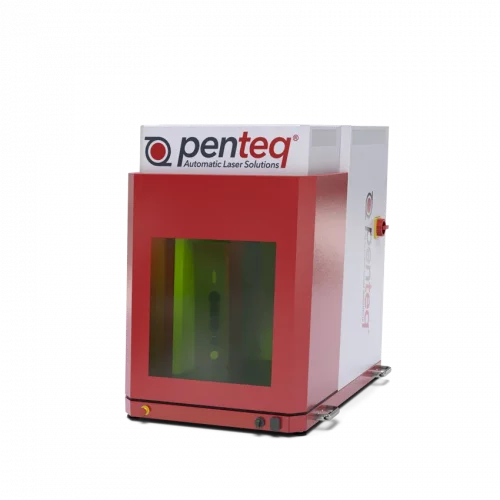

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Integration station

Laser system for easy integration into conveyors

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

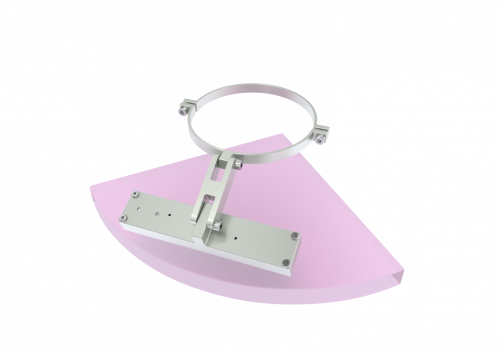

FM focus finder

Easily detect the component height with the focus finder function module

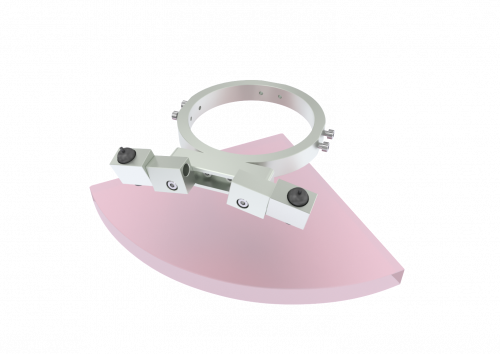

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Further applications

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

Perforating and punching

Precision laser perforation for demanding materials.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments