Technical films

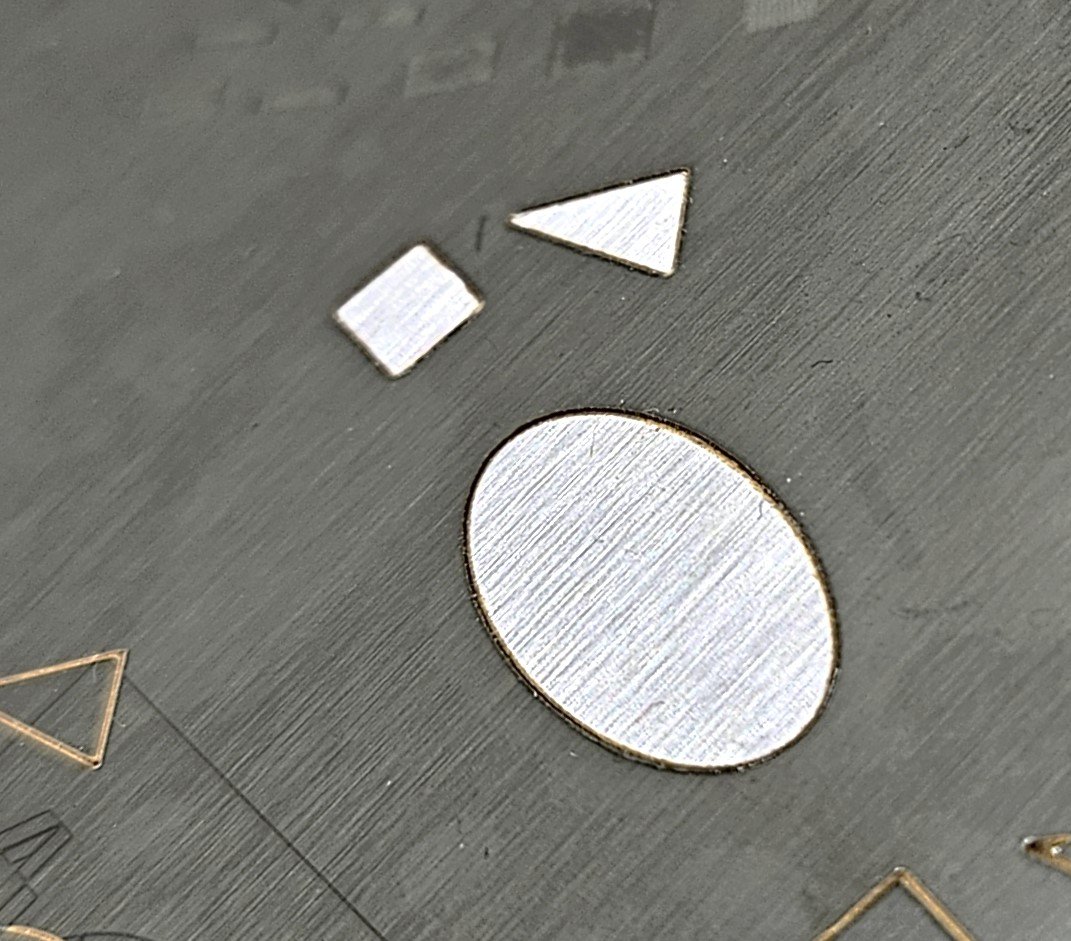

Precise, fast and clean cuts

Laser cutting of foils with galvo systems

Precision, speed and flexibility for the highest demands

The advantages of scanner laser cutting at a glance

Flexible and economical

- Ideal for changing contours, small batches or customisation - without changing tools.

- Efficient: "Just-in-time production" as required No minimum quantities per contour variant

No surplus production (waste of material)

Low procurement and administration costs

Non-contact and wear-free

- No tool contact, no deformation due to the application of force

- No tool costs

Precise

- Outstanding cutting quality

- Clean cut edges and minimal burr formation

- Low thermal load

Highest processing speed

- Thanks to dynamic beam guidance through the galvo mirrors - ideal for large quantities and short cycle times.

- Cut sensitive materials without breaking or burning.

Laser cutting of films using the roll-to-roll process

The precise and economical processing of films plays a key role in industrial production - especially in high-tech sectors such as electronics, medical technology and automotive. One of the most innovative technologies in this area is laser cutting using the roll-to-roll process, in which the material - thin plastic, metal or composite films - is continuously unwound from a roll, processed and then wound up again. Laser cutting enables contact-free, high-precision cuts, even with the finest structures or sensitive materials. Advantages of laser cutting using the R2R processHighest precision: Micro cuts down to the sub-millimetre range are possible without any problems - ideal for electronic components, sensors or medical components.

Non-contact & wear-free: No tool contact means less mechanical stress and no tool wear.

Flexibility in contour design: Geometries can be adapted quickly and without mechanical changes.

High process speed: The continuous material feed enables fast cycle times - even for complex patterns.

Clean cut edges: No fraying or smouldering as with mechanical processes.

Variety of materials: From PET and polyimide to metallised films - almost any type of material is suitable.

Some typical applications:

Flexible printed circuit boards and circuits

Carrier films for microcomponents

Masks and cover films in medical technology

Touch sensors and displays

Sealing films for automotive applications

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

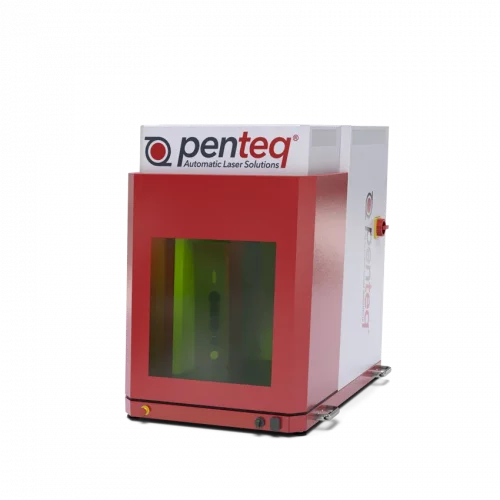

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

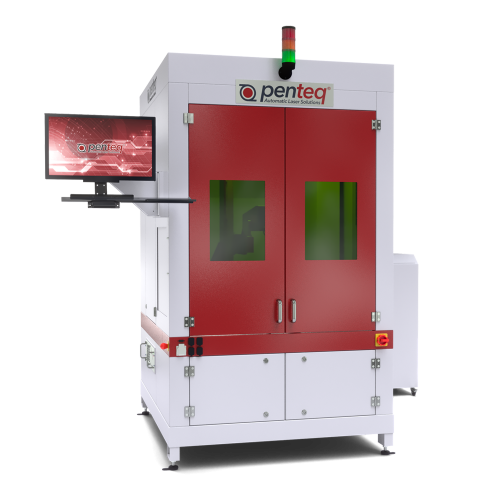

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

OEM Carbonline

CO₂ technology for versatile applications

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

LG500 A Double shutter

Automatic loading system for large workpieces

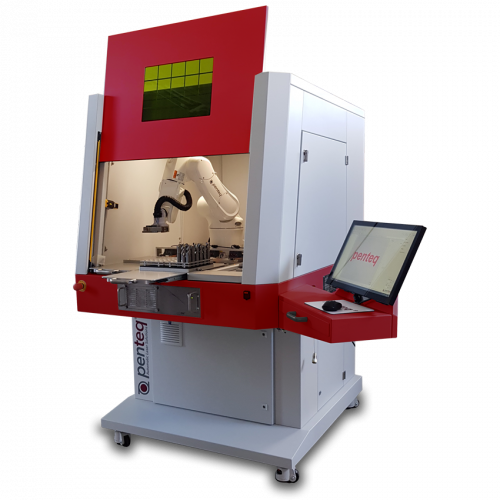

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

Integration station

Laser system for easy integration into conveyors

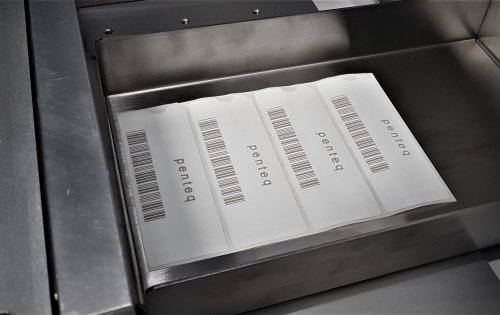

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Further applications

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

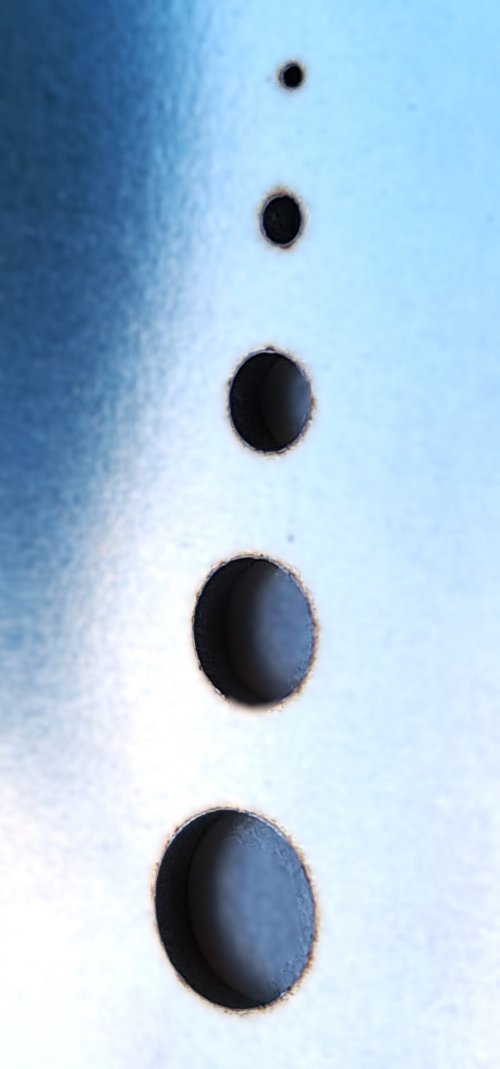

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments