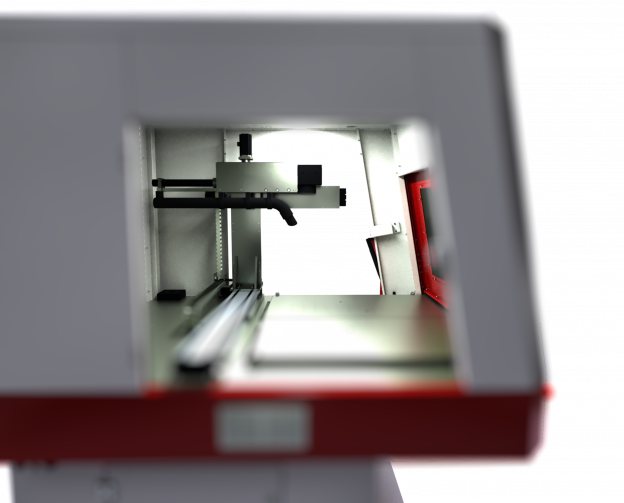

Laser workstation LG 300 - The solution for large workpieces and high quantities

Spacious work area and double pull-out table for maximum throughput rates

You can also visit the LG300 laser workstation on our

LG 300 LaserWorkStation - perfection for large workpieces and series labelling

The Penteq LaserWorkStation LG300 was developed to offer maximum flexibility and efficiency in industrial laser technology. With its generous working area of 1000 x 500 x 300 mm, it is equally suitable for processing numerous small workpieces in a single load or large, heavy workpieces made of materials such as steel, stainless steel, aluminium or plastics. The robust design and well thought-out ergonomics make the LG300 the ideal choice for demanding industrial applications.

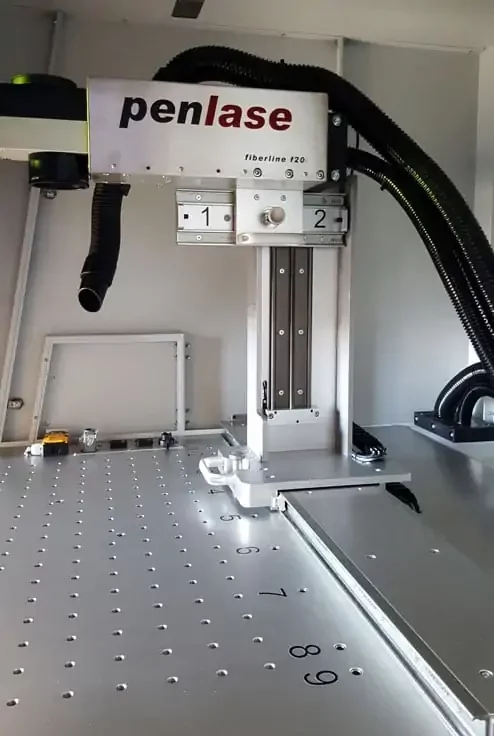

The double extension table system - intelligent technology and first-class precision

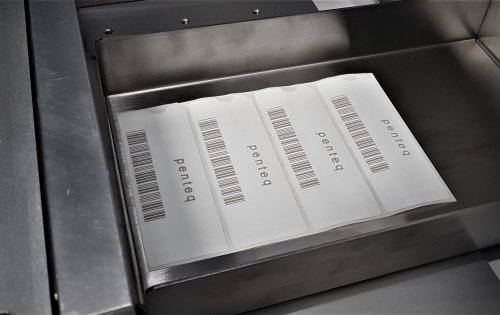

The innovative double pull-out table concept of the LG 300 LaserWorkStation enables optimised processing thanks to two independently usable table areas. While one table is being labelled, the other can be loaded or unloaded in parallel.

Advantages of the system:

- Increased loading capacity: Rectangular table supports utilise space more efficiently than conventional turntables.

- Maximum work surface: Full table support of 1000 x 500 mm when the tables are pushed in.

- Extended functionality: More space for additional modules such as rotary axes or CardMaker.

- Flexibility through partitioning: Stations on the left and right-hand sides enable parallel processes.

- Increased productivity: Simultaneous loading and unloading saves valuable time.

- Automated operation: Integrated control technology for smooth processes.

Discover the possibilities

The LG 300 laser workstation is the solution for labelling large workpieces or a large number of small workpieces.

High productivity

The optional double pull-out table module enables simultaneous loading and unloading during the labelling process, ensuring a high throughput when processing large quantities.

The robust, powder-coated steel construction of the protective cabin is designed for many years of industrial use. Even the basic version includes all the necessary components for reliable operation.

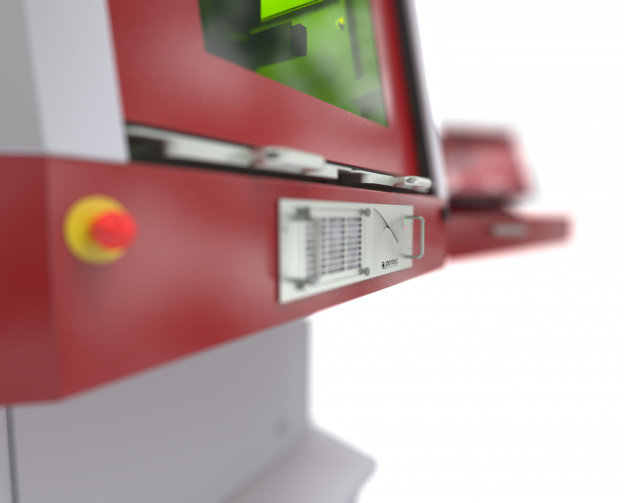

Large loading door

The generously dimensioned, upward-sliding loading door ensures optimum access to the work area.

To minimise non-productive times, the door stroke can be limited by the control system to eliminate empty travel. The CE-certified laser safety window offers safety and a clear view of the process.

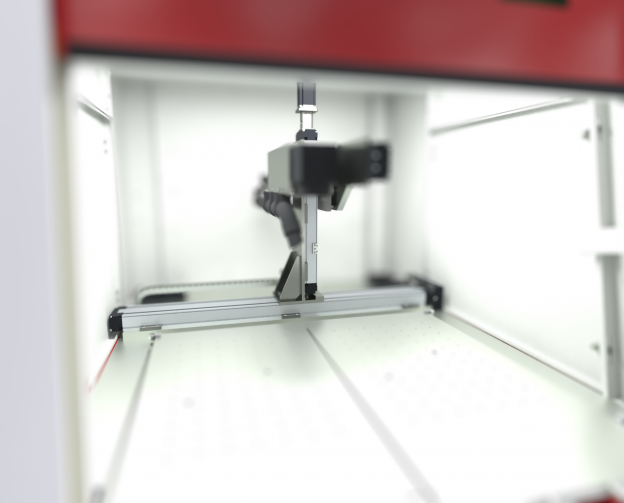

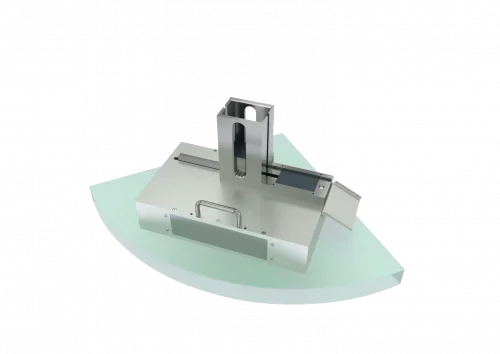

Variant with manual X-Y axis

The system is usually equipped with at least three NC-controlled axes (X, Y, Z). For simple applications, such as labelling large workpieces at a fixed position, a more cost-effective version with manually adjustable X and Y axes is available.

Scales and grid positions ensure high repeat accuracy.

Continuous product traceability

In combination with the PenApp Track'n Trace, a seamless product traceability system can be integrated.

This fulfils demanding quality assurance and data processing requirements and takes individual customer wishes into account.

Castors - For easy mobility

The LaserWorkStation LG300 can be optionally equipped with sturdy castors that allow the system to stand securely and be moved easily.

This solution is ideal for flexible production environments where the location needs to be adjusted regularly.

Installation

Thanks to its sophisticated design and modular construction, the LG300 can be seamlessly integrated into existing production lines.

The compact design enables optimum utilisation of the available space, while the control integration ensures efficient process handling.

| Workspace dimensions | 1100 x 500 x 300 mm (WxDxH) |

| Active medium | Yb fibre laser, UV laser, Signolux, CO₂ laser |

| Standard performance | 4 - 2000 Watt |

| Simple marking field | 150 x 150 mm (other sizes on request) |

| Maximum workpiece weight | 100 kg |

| Security | Laser class 1 |

| Dimensions (WxDxH) | 1250 x 1510 x 2300 mm |

| Weight | 580 kg |

- Pivot axis

- Extendable table

- Labelmaker

- Cardmaker

- X/Y table

- Robot transfer

- Linear conveyor

- Ring conveyor

- DMC camera

- Focus finder

- Automatic door

- Manual Y-axis

Software

- PMS - Penteq Marking Software

- Penteq App Development

Accessories

- DMC Camera - VisionSystem Verifier

- Pilot laser

- Laser fume extraction

- Manual Y-axis

- Foot switch

- Monitor on swivel arm

- Hand scanner for codes

- touch screen

- Bad parts box

- 3-stage status light

- Fiberline F20

- Fiberline F30

- Fiberline F50

- Fiberline F100

- Fiberline F120

- Fiberline F150 Q-CW

- Fiberline F300 Q-CW

- Fiberline F500

- Fiberline F1000

- Fiberline F2000

- Carbonline C30

- Carbonline C60

- Carbonline C120

- UV Line

- Greenline

Matching products

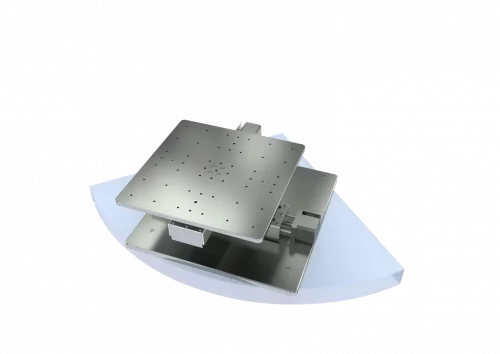

FM XY table

The automatically movable X/Y table enables the marking field to be enlarged in the X and Y directions

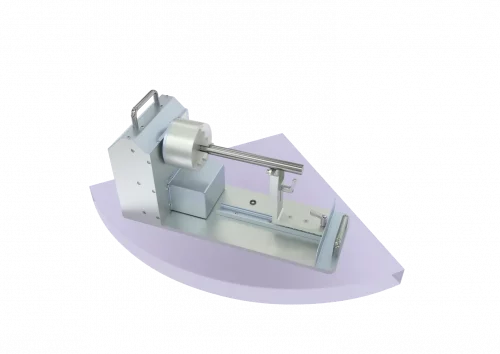

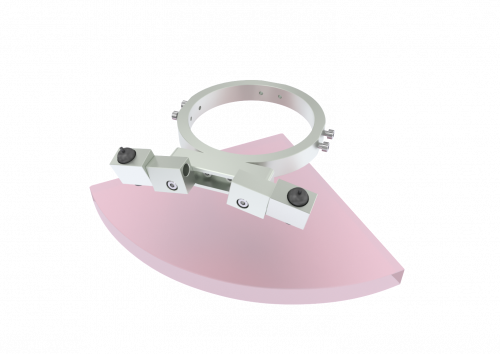

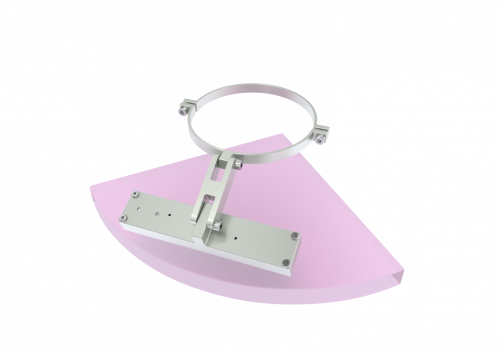

FM Rotary axis

The rotary axis function module (dividing head) is used for segmental labelling of the lateral surface on cylindrical components.

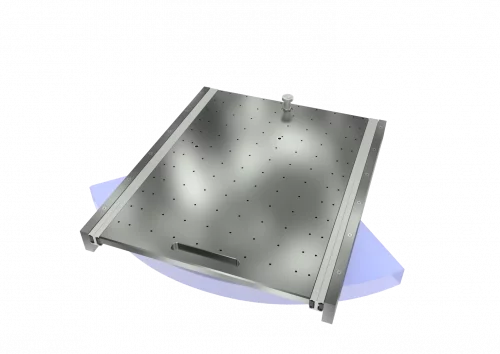

FM Extendable table

The door can be opened completely and the support table pulled out towards the operator for adjustment and set-up work, as well as for picking up large or heavy parts.

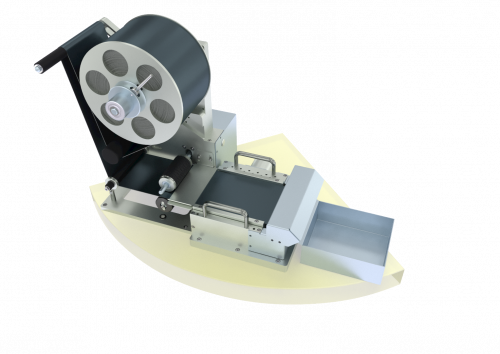

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

PenSoft Control

Easy-to-use interface for laser applications

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

OEM Greenline

Precision laser for sensitive material processing

Signolux UKP Pico

Precision & quality for the highest demands

Signolux UKP femto

Precision & quality for the highest demands

OEM fibreline high power

Ready-to-install laser for numerous applications

Applications

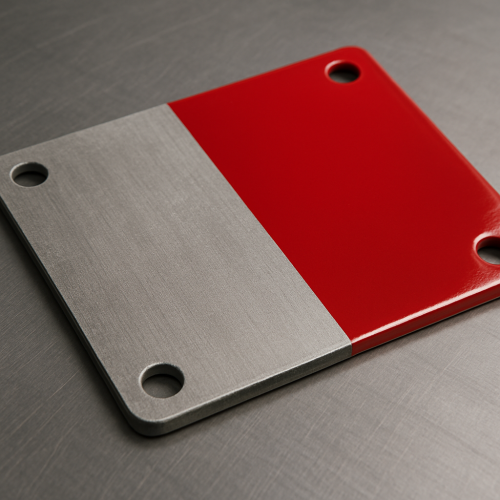

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

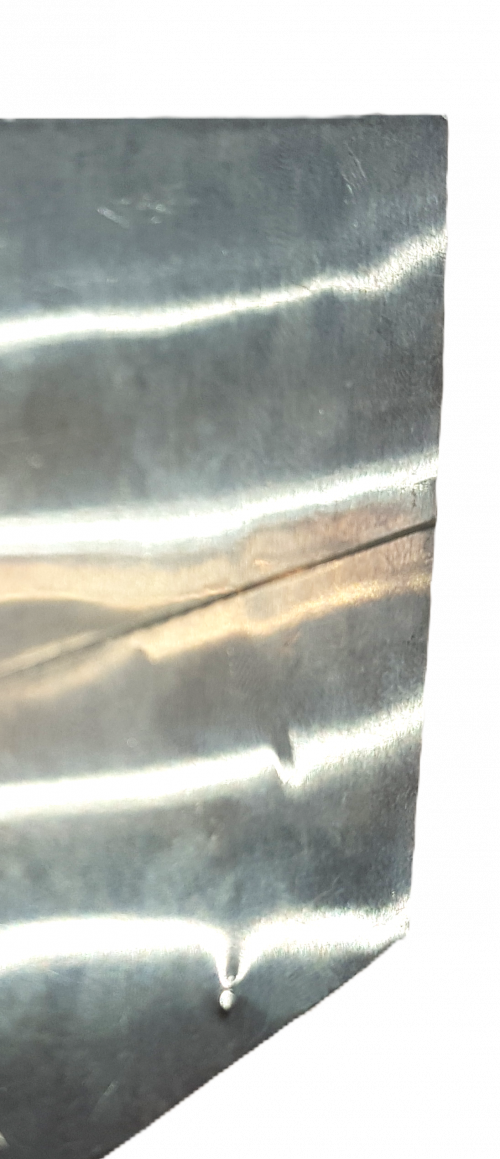

Paint stripping

Removing paint without chemicals or blasting media

Cutting tools

Flexible and durable laser labelling

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

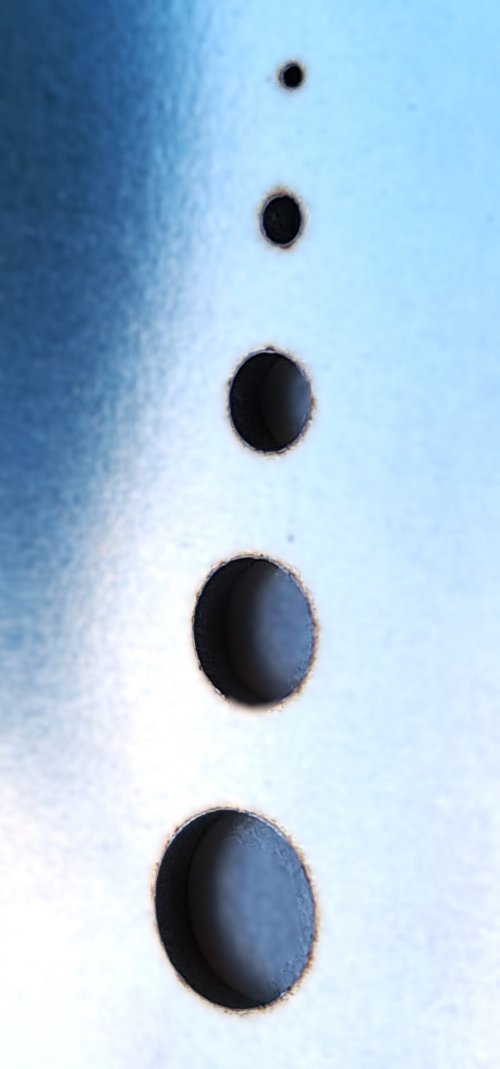

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Watch components

Precisely joining what belongs together

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling