Laser welding watch components

DPW - Laser welding of watch parts

The finest welding technology for the highest art of watchmaking

Maximum precision and absolute reliability are essential in the watch industry - especially when joining precision mechanical components. Laser welding has established itself here as a key technology for joining watch parts reliably, precisely and without visible seams. Whether in the production of high-quality components or the repair of historical timepieces, the use of lasers enables low-stress, precise welding without thermal stress on neighbouring areas, and thanks to the non-contact process, laser welding is ideal for sensitive materials such as stainless steel, gold, titanium or platinum. Even the finest workpiece geometries and complex shapes can be joined precisely - with a minimal heat-affected zone, without distortion or discolouration. The technology is not only suitable for manufacturing, but also for precise repairs to strap lugs, case horns, clasps or movement components.

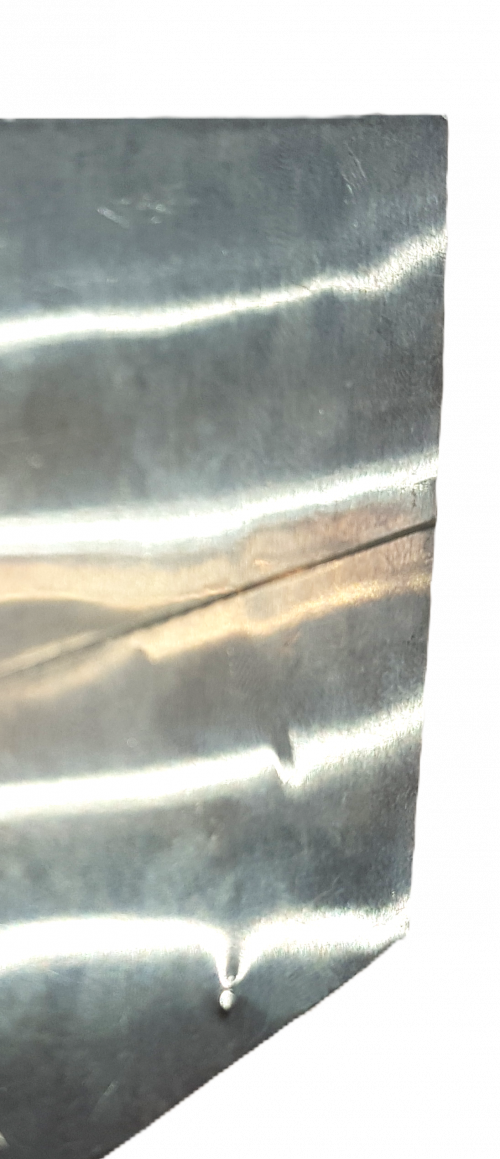

Laser welding of stainless steel bracelets for high-quality watches enables precise and stable connections with minimal heat input - ideal for delicate components and sophisticated designs.

The fine weld seams can be positioned precisely and offer high strength while minimising distortion.

Light finishing, such as polishing or fine grinding, is usually sufficient to completely match the look of the weld seam to the bracelet finish - especially in visible areas in the high-end segment.

DPW Dynamic Precision Welding

Laser welding of watch parts with dynamic beam guidance

The high-precision welding technology with scanner and integrated camera is an innovative technology for the highest demands in the watch industry

The joining of precision mechanical watch parts places the highest demands on precision, process reliability and reproducibility.

The use of dynamic beam guidance by galvo scanners and an integrated camera opens up new dimensions in automated micro-welding technology for the watch industry. The scanner-guided laser beam allows welding positions to be controlled extremely quickly and precisely - without mechanical movement of the workpiece. This reduces cycle times, increases repeat accuracy and enables maximum flexibility for a wide range of geometries. The process is supported by an integrated camera, which enables live positioning, component recognition and quality control directly in the process.

This technology is ideal for manufacturers of high-quality watches who want to combine series production, quality assurance and aesthetic requirements at the highest level.

Suitable materials:

Stainless steel, titanium, gold, platinum

Bimetals, alloys

Thin-walled precision parts with high optical requirements

Typical applications:

Joining of case components, clasps, strap lugs

Precision welding of bridges, spring arms, movement holders

Repair and restoration with documented precision

Series assembly of small parts

Integration into automated watch assembly lines

High-tech meets craftsmanship - laser technology in the manufactory

The manufactory has always stood for the highest level of craftsmanship, attention to detail and the aspiration to produce every component with care and perfection. In this world of precision and aesthetics, laser technology opens up new possibilities: it complements traditional manufacturing methods with digital precision, contactless processing and reproducible results - without displacing the character of craftsmanship. Particularly in watch manufacture or the precision mechanical production of sensitive small parts, lasers enable the finest engravings, microscopically precise welded joints or flawless markings - where manual labour alone reaches its physical limits. At the same time, the technology preserves the integrity of the materials and fulfils the highest aesthetic requirements. Laser technology thus becomes a silent partner in the background: invisible in its realisation, but irreplaceable in the result - as a link between innovation and tradition, between digital precision and craftsmanship.

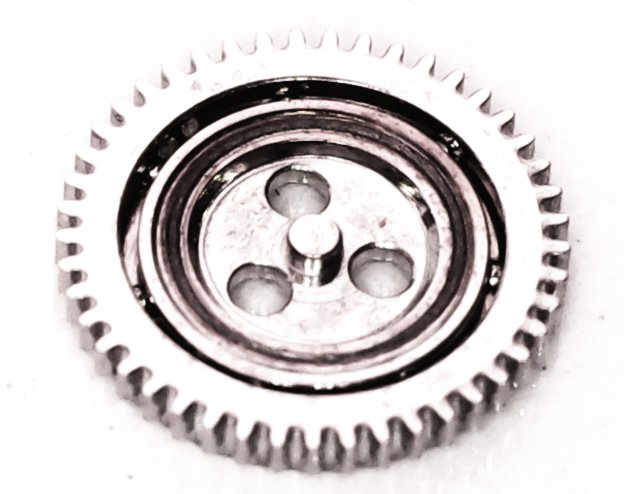

The dynamic laser welding of micro gears in watch production requires maximum precision with minimal heat input. By using a galvanometric scanner system in combination with an integrated camera (DPW system), position detection and beam guidance take place in real time - ideal for the exact joining of extremely small components.

The precise beam deflection enables short cycle times and the finest seam geometries, while the camera-based position detection automatically compensates for positioning tolerances. The result is a reproducible, resilient joint - perfectly matched to the mechanical and aesthetic requirements of high-quality watch movements.

Advantages of DPW scanner-guided laser welding for watch parts

Extremely precise weld positioning

- Weld seam guidance by galvo scanner

- Dynamic live seam detection with integrated camera

- Automatically compensates for production tolerances

- Low thermal load thanks to finely adjustable laser pulses

- High process speed

Automatable and reproducible

- Collision-free operation and therefore ideal for complex geometries and micro parts

- Ideal for integration into series production

- No movement of the component

- Automatic position detection and compensation

Perfect for industry & manufacturing

This advanced laser welding technology is suitable for both industrial watchmakers and exclusive manufacturers who value the highest quality, aesthetics and documentability.

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG150

The all-rounder in industrial laser technology

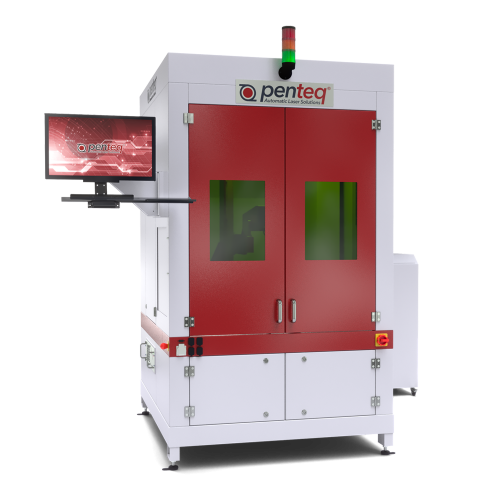

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

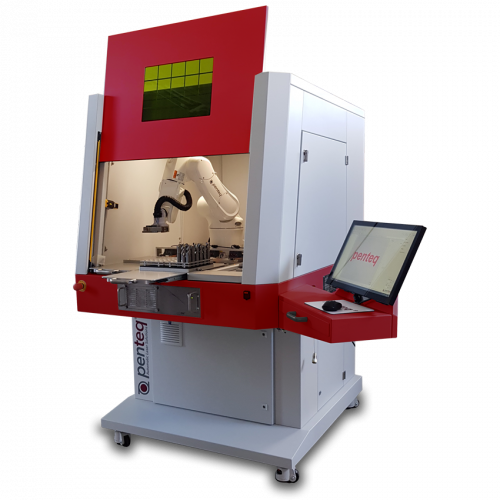

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Industries

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces