Stripping

Stripping & stripping of copper wires for the electronics industry

Stripping

Precise, non-contact and reliable wire preparation for modern production processes

Laser systems from Penteq offer the perfect solution for customer-specific requirements for process-reliable and highly productive systems for the residue-free removal of insulating plastics.

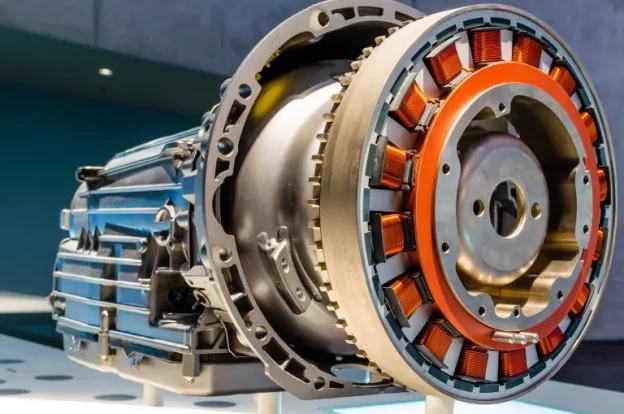

Laser stripping of enamelled copper wires

Enamelled copper wires (also known as insulated copper wires or magnetic wires) are used in a wide range of electrical applications - from transformers and electric motors to high-frequency coils in communications and automotive technology. The removal of the insulation layer - an essential step before contacting, soldering or crimping - places particular demands on precision, reproducibility and material protection.

Laser stripping is establishing itself as a modern, high-precision alternative to mechanical or chemical processes. It is non-contact, wear-free, gentle on materials and ideal for automated production lines.

What is laser stripping?

Laser stripping utilises targeted laser energy to selectively remove the enamel or enamel coating from copper wires - without damaging the underlying copper. The insulation enamel is vaporised or removed using precisely controllable parameters, while the underlying metal structure remains intact.

Typical insulation materials:

- polyurethane

- polyesterimides

- Polyamide imides

- Polyetheretherketone (PEEK)

- Special coatings for high frequency or high temperature

Advantages over conventional methods

| Kriterium | Mechanisch/Chemisch | Laserverfahren |

|---|---|---|

| Kontaktfreiheit | ❌ Werkzeugkontakt | ✔️ Berührungslos |

| Werkzeugverschleiß | ❌ Regelmäßiger Austausch | ✔️ Kein Verschleiß |

| Prozessgenauigkeit | ❌ Toleranzen durch mechanische Kräfte | ✔️ Mikrometergenaue Steuerung |

| Materialschonung | ❌ Gefahr von Drahtbeschädigung | ✔️ Keine mechanische Belastung |

| Umweltaspekte | ❌ Einsatz von Lösungsmitteln | ✔️ Trocken, umweltfreundlich |

| Automatisierung | ⭕ Eingeschränkt | ✔️ Hoch automatisierbar |

Functionality and process parameters

Laser stripping is carried out in a controlled process in which specific parameters are precisely adapted to the wire diameter, insulation material and geometry.

Relevant parameters:

- Laser source: fibre laser, diode laser, UV or CO₂ laser - depending on the insulation material

- Wavelength: typically 1064 nm (IR) or 355 nm (UV) for finer coatings

- Power & pulse duration: short pulse or continuous wave, depending on the application

- Removal strategy: spiral, line or dot removal

- Positioning: by scanner, CNC gantry or robot arm

Suitable wire types:

- Round wire (Ø 0.05 mm - 2 mm)

- Rectangular wire / flat wire

- Stranded wire and multi-core cables (partly with restrictions)

Application examples

Automotive industry

- Stripping of winding wires for electric motors (e.g. hairpin technology)

- Preparation for ultrasonic welding or crimping

Electrical engineering & transformer construction

- Wire contacting without damaging the winding

- Consistent quality for mass production

Medical technology & sensor technology

- Ultra-fine wires with very thin insulation

- Absolute process purity required (no abrasion, no flux)

Quality assurance and validation

Clean stripping is a prerequisite for good electrical and mechanical connections. The quality of the laser ablation can be tested using the following methods:

- Microscopy: evaluation of the surface structure

- Contact resistance measurement: quantifying connection quality

- Tensile tests / pull-off force measurement

- Inline camera control for process monitoring

Optionally, systems can be combined with automatic position detection and removal control to minimise rejects. minimise waste.

Integration in production environments

Modern laser systems have a modular design and can be easily integrated into production lines or cells. Typical interfaces:

- PLC / fieldbus systems

- Robot connection

- Vision systems for position detection

Inline processes can be realised with cycle times in the seconds range - without significant downtimes.

Economic and ecological aspects

- Reduction in operating costs due to elimination of tool wear

- No chemical waste or solvents

- Low maintenance - high system availability

- Reproducibility minimises rework and quality fluctuations

Highly precise, reliable & future-proof

Laser stripping of enamelled copper wires is a highly precise, reliable and future-proof process. It enables contactless and non-destructive preparation of wire connections - ideal for automated production processes in demanding industries. The combination of quality, process reliability and environmental friendliness makes the process a clear alternative to conventional stripping methods.

Get advice now

Our experts will support you in selecting the right technology for your application.

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

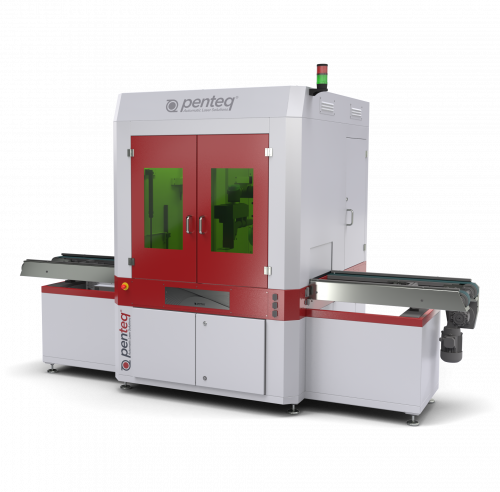

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

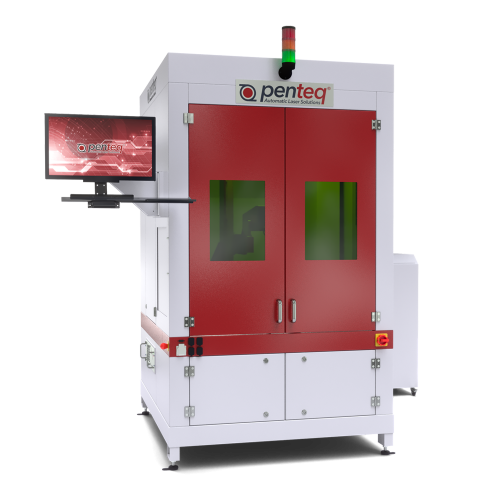

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

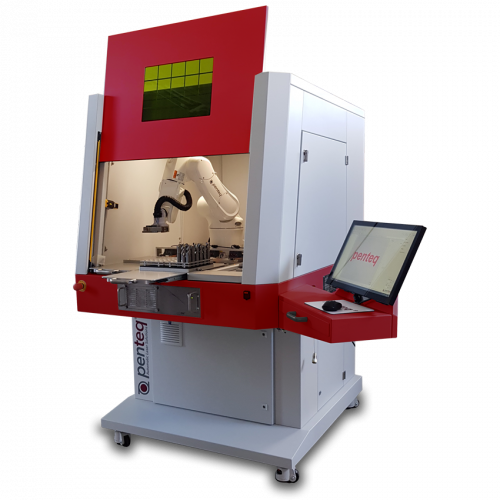

SG 500 RoboLaser

Flexibility through laser robots

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

OEM Carbonline

CO₂ technology for versatile applications

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Further applications

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Rust removal

Efficient laser cleaning of corroded surfaces

Industries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments