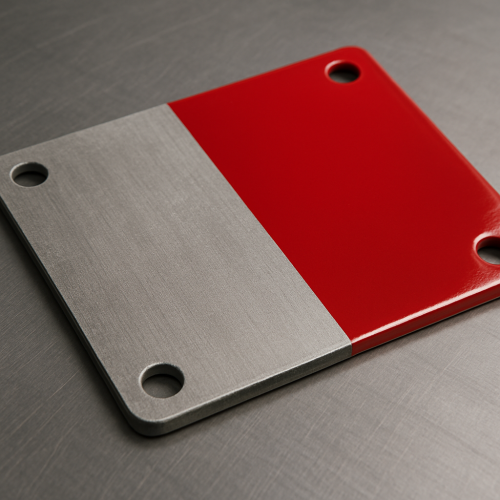

Rust removal from metal workpieces

Rust removal by laser

Fast and selective laser cleaning of corroded surfaces

In modern metalworking, the removal of rust and oxidation is crucial to ensure the service life and functionality of components. One of the most innovative technologies in this area is laser rust removal. This method offers numerous advantages over conventional processes and is becoming increasingly established in the industry.

Laser derusting is a process in which high-intensity laser beams are used to remove rust, oxidation and other contaminants from metal surfaces. The laser beam is directed precisely at the affected areas, causing the unwanted layers to be vaporised or removed by the high temperature. This is done without the use of chemical agents or abrasive materials, which significantly reduces the environmental impact.

We offer solutions for small quantities as well as for the production of large and very large quantities with automated systems.

Laser derusting is a revolutionary method of removing rust and oxidation that is both environmentally friendly and efficient. As laser technology continues to develop, this method will become even more important in metalworking. Companies looking for innovative solutions to improve their production processes should consider laser rust removal to increase their competitiveness while being environmentally conscious.

Advantages of laser derusting

Environmentally friendly

- As no chemical cleaning agents or abrasive materials are used, the process is environmentally friendly. Compared to other methods such as dry ice cleaning, high CO² emissions are avoided.

- Laser cleaning avoids waste as the laser beam is targeted at the affected areas. The removed layers of rust and oxide are usually removed in the form of vapour or fine particles, which can be easily captured by a special fume extraction system and filtered out of the air.

- In contrast to some chemical cleaning processes, which require large quantities of water to rinse off the chemicals, laser derusting does not use any water, which significantly reduces water consumption.

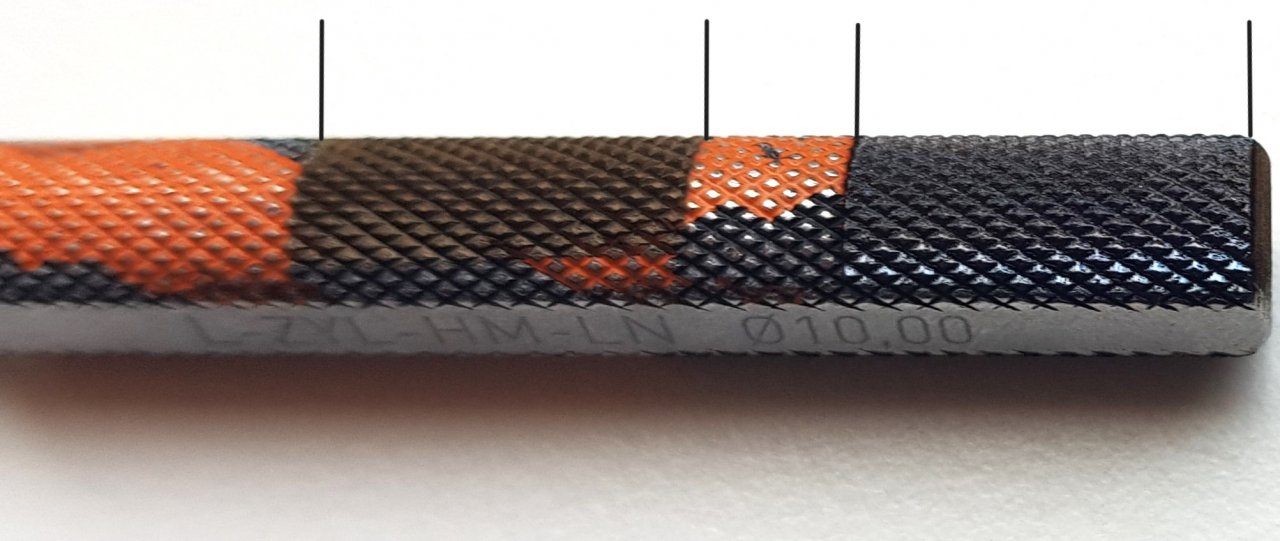

Precise

- Laser derusting enables very precise processing, making it possible to reach areas that are difficult to access without damaging the underlying material.

- Selective processing means that only the required areas can be cleaned.

Efficient

- The speed of the laser process results in considerable time savings compared to traditional methods such as sandblasting or chemical treatments.

High surface quality

- Laser derusting leaves a clean and even surface that is ideal for subsequent processing steps such as coating or welding.

Suitable products

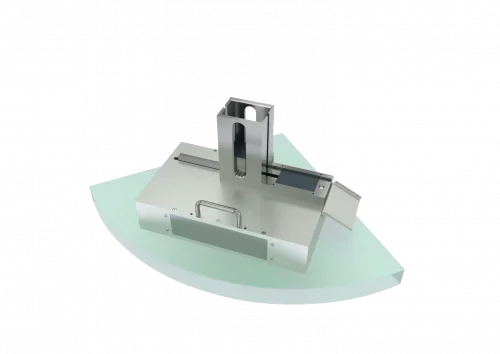

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

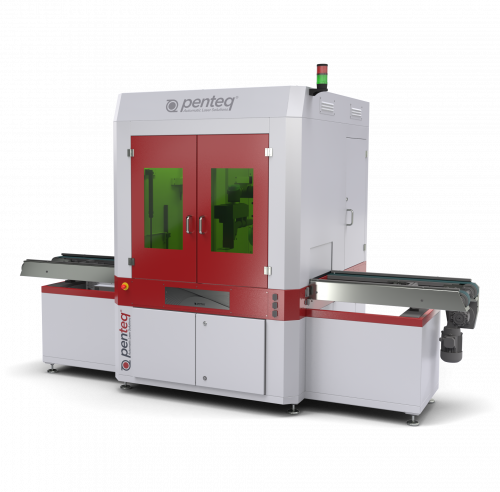

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

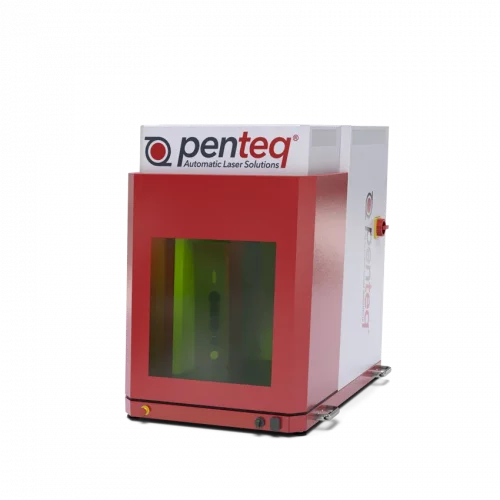

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

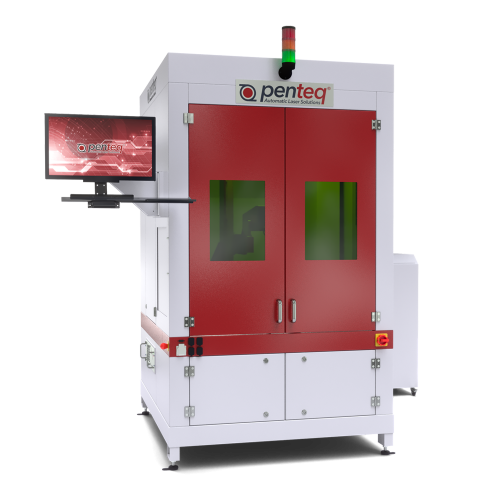

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

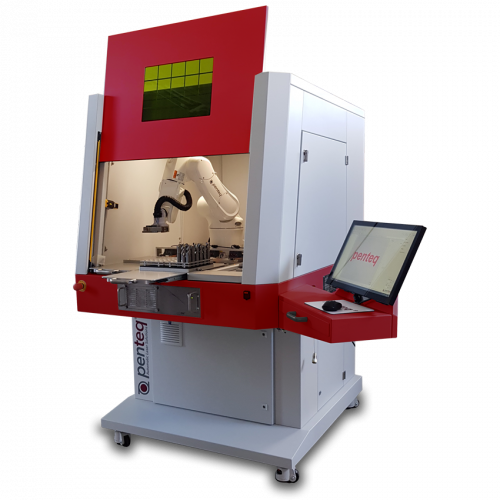

SG 500 RoboLaser

Flexibility through laser robots

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

Further applications

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments