Rust removal from metal workpieces

Rust removal by laser

Fast and selective laser cleaning of corroded surfaces

In modern metalworking, the removal of rust and oxidation is crucial to ensure the service life and functionality of components. One of the most innovative technologies in this area is laser rust removal. This method offers numerous advantages over conventional processes and is becoming increasingly established in the industry.

Laser derusting is a process in which high-intensity laser beams are used to remove rust, oxidation and other contaminants from metal surfaces. The laser beam is directed precisely at the affected areas, causing the unwanted layers to be vaporised or removed by the high temperature. This is done without the use of chemical agents or abrasive materials, which significantly reduces the environmental impact.

We offer solutions for small quantities as well as for the production of large and very large quantities with automated systems.

Laser derusting is a revolutionary method of removing rust and oxidation that is both environmentally friendly and efficient. As laser technology continues to develop, this method will become even more important in metalworking. Companies looking for innovative solutions to improve their production processes should consider laser rust removal to increase their competitiveness while being environmentally conscious.

Advantages of laser derusting

Environmentally friendly

- As no chemical cleaning agents or abrasive materials are used, the process is environmentally friendly. Compared to other methods such as dry ice cleaning, high CO² emissions are avoided.

- Laser cleaning avoids waste as the laser beam is targeted at the affected areas. The removed layers of rust and oxide are usually removed in the form of vapour or fine particles, which can be easily captured by a special fume extraction system and filtered out of the air.

- In contrast to some chemical cleaning processes, which require large quantities of water to rinse off the chemicals, laser derusting does not use any water, which significantly reduces water consumption.

Precise

- Laser derusting enables very precise processing, making it possible to reach areas that are difficult to access without damaging the underlying material.

- Selective processing means that only the required areas can be cleaned.

Efficient

- The speed of the laser process results in considerable time savings compared to traditional methods such as sandblasting or chemical treatments.

High surface quality

- Laser derusting leaves a clean and even surface that is ideal for subsequent processing steps such as coating or welding.

Suitable products

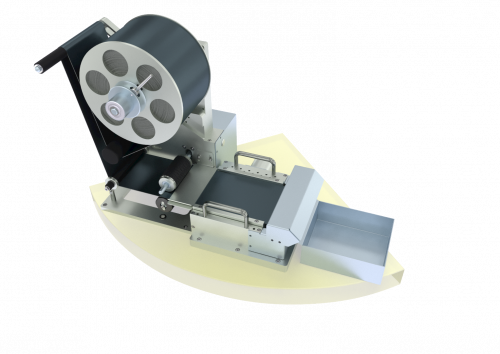

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

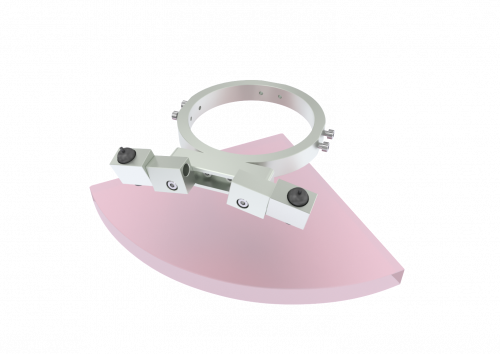

FM focus finder

Easily detect the component height with the focus finder function module

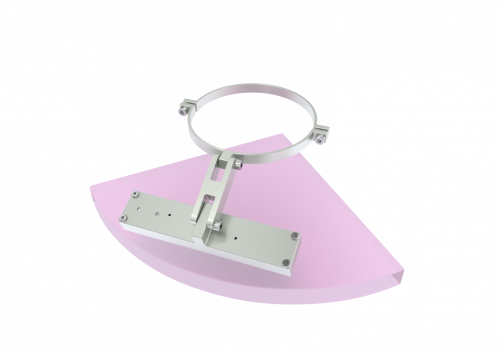

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

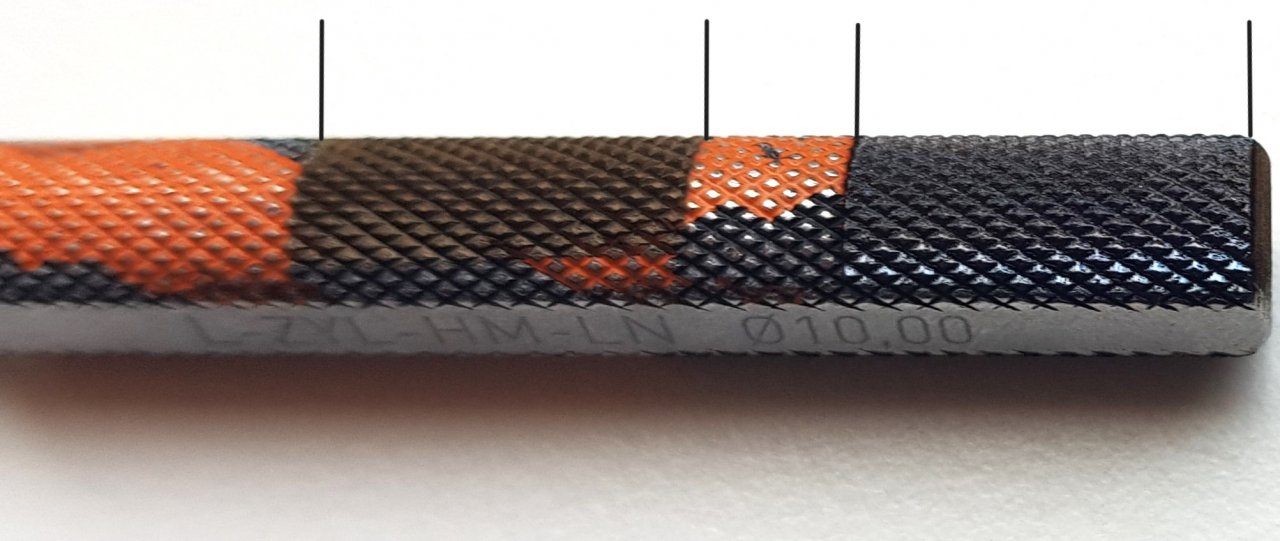

OEM fibreline high power

Ready-to-install laser for numerous applications