Tool manufacturer

Penteq laser systems offer tool manufacturers maximum precision and efficiency. Their non-contact processing enables precise engraving, shortens production times and minimises tool wear.

Penteq in tool manufacture

Penteq laser systems impress tool manufacturers with their ability to mark tools with the utmost precision and attention to detail. Non-contact laser processing guarantees that every tool is labelled gently - from fine contours to precise dimensions. This results in long-lasting markings that impress even under demanding operating conditions. At the same time, the efficient machining processes enable shorter production times and reduce material wear, resulting in significant cost savings.

Products

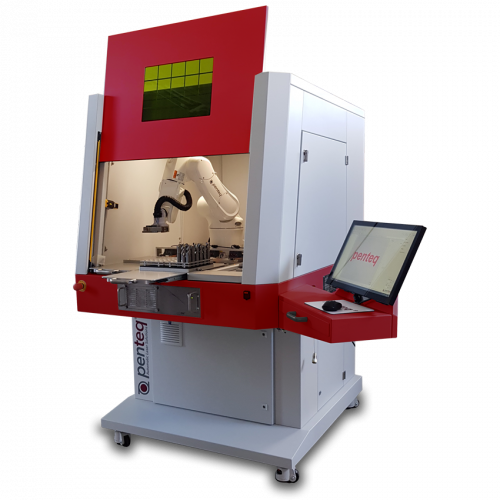

SG 500 RoboLaser

Flexibility through laser robots

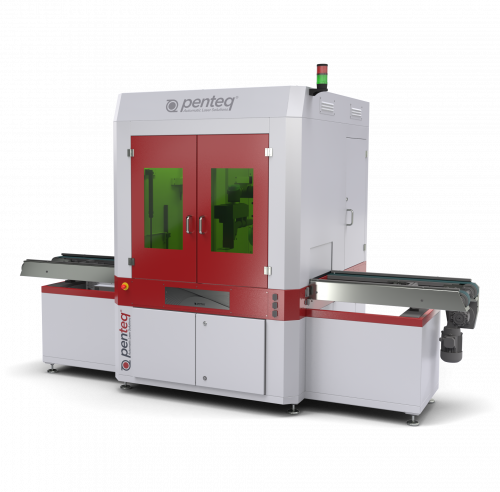

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

LG500 A Double shutter

Automatic loading system for large workpieces

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

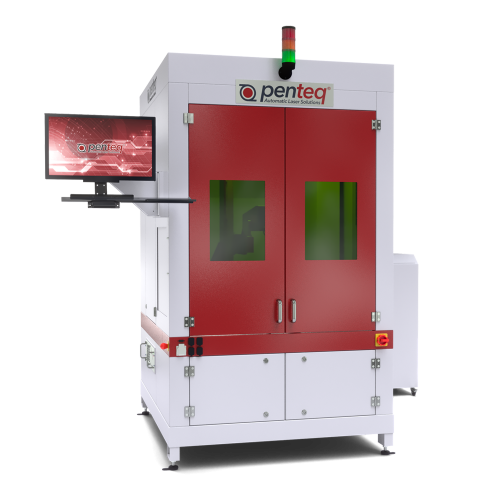

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors