Type plate laser machine LG300 PL SB50

For all types of signs

You can also visit the nameplate laser machine on our

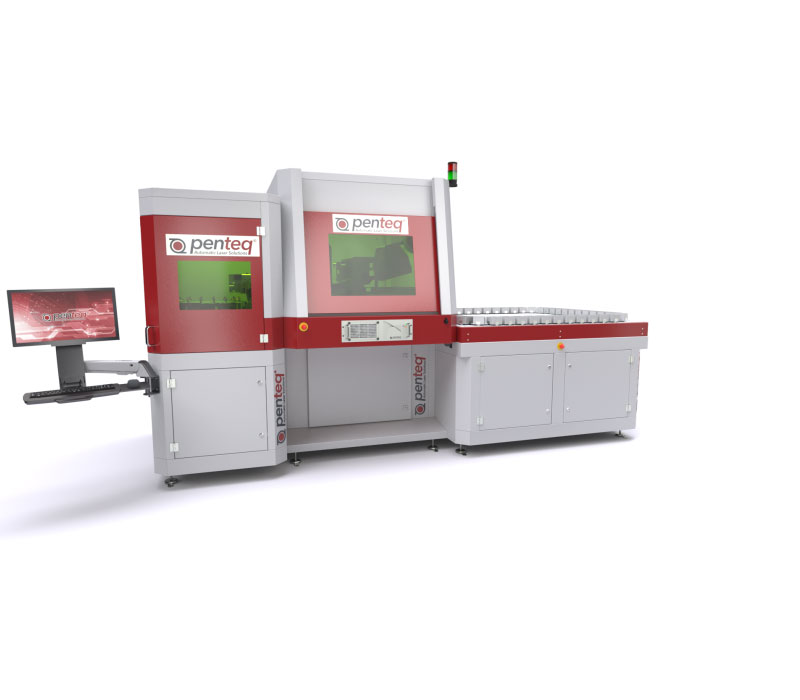

Maximum productivity and flexibility with the LG 300 PL SB50 nameplate laser machine

Many years of experience in the field of type plate production have been incorporated into the development of the machine and software and have resulted in a system optimised for the labelling of type plates, which is used by leading manufacturers in the industry. The modular design ensures a high degree of flexibility and enables production as a series machine.

Modularity is the central concept of our laser systems and offers you a smart, cost-efficient solution for a wide range of requirements in nameplate production in series production. Additional functionalities such as a labeller can also be integrated. An optional packaging system is also available on the output side.

The integrated penlase fiberline is a powerful, air-cooled laser that is characterised by particularly high reliability. It offers the best quality for marking both anodised aluminium signs and stainless steel signs and guarantees the high-contrast creation of barcodes, Data Matrx codes or QR codes for easy readability.

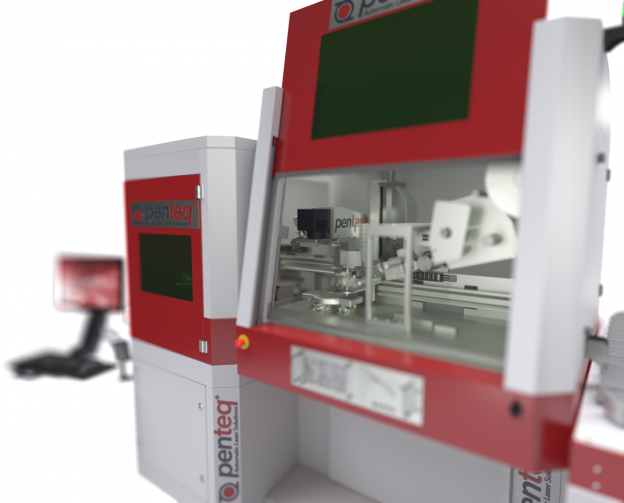

Laser labelling and sorting with maximum capacity

The LG 300 PL SB50 type plate laser machine produces the type plates in the required order, labels them and places them sorted in 50 sorting boxes.

An optional vision system checks the codes for legibility based on the AIM-DPM or TR 29158 standard to ensure consistent traceability. The result can be saved with a time stamp.

Complete turnkey solution including software connection

Robust machine frame in welded steel construction with powder-coated sheet steel panelling for many years of industrial use. The basic equipment includes all supply units for the laser, the turret magazine and an extraction unit integrated into the control system.

Easy-to-use software with integrated editor for quickly creating layouts based on Windows 11. Transfer of variable data and layouts from an ERP system via Ethernet, additional functions such as job archive or print job for labels are available.

50 sorting boxes

The automatic ring conveyor positions the sorting boxes in the correct position and according to the position selected in the software under the output point for the type plates. This enables order-related sorting of the ready-labelled type plates. If the number of labels exceeds the maximum capacity of the selected sorting box, the order is automatically split between two or more boxes.

The special design of the ring conveyor enables permanent access to the sorting boxes. Rush or test orders can also be produced manually in between. The system also has an automatic front door, which can also be used for labels with special formats.

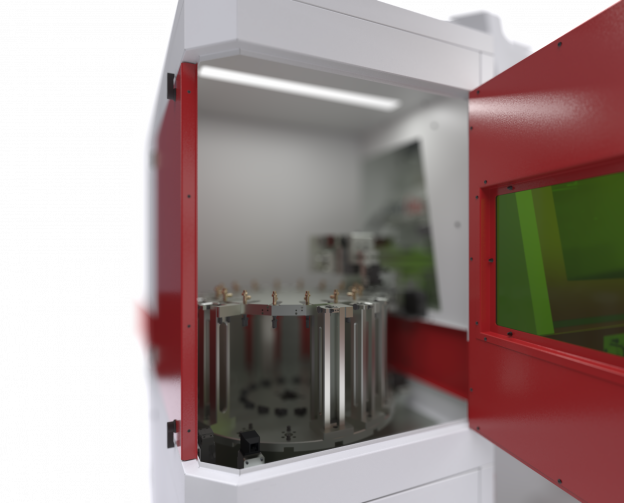

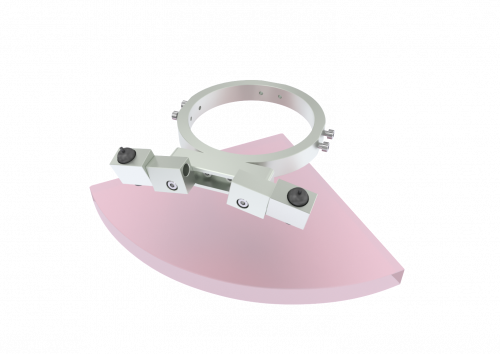

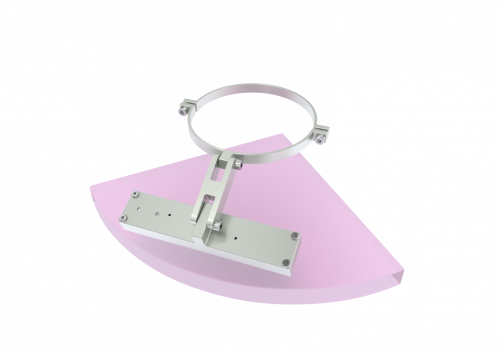

Revolver magazine for various rating plates

The magazines can be changed without tools in just a few moments.

To ensure that the magazines can only be inserted in the correct position, they are designed as poka-yoke. The filling height is 250mm.

The turret magazine positions the selected magazine to the transfer position.

To optimise cycle times, the manoeuvring movements take place during the laser process, thus ensuring the fastest possible processes.

Ready for data exchange

The integrated industrial PC and the Windows-based control system offer the best conditions for seamless integration of the laser system with the user's IT system. Connection to ERP systems is easy to realise thanks to standardised interfaces. The Penteq framework enables customised adaptations for a wide variety of processes.

Small footprint due to compact dimensions

The laser system is equipped with adjustable machine feet for standard hall floors.

The robust design allows easy manipulation using a pallet truck or forklift. The space-saving design of the all-in-one solution combines all functions in one system.

Optimum operability

The screen, keyboard and mouse are mounted on an ergonomically height and tilt-adjustable, solid swivel arm.

It is controlled and operated using PenSoft software specially developed for nameplate production, which is easy to use after a short briefing.

Layouts are created using an intuitive editor, which offers all the usual options for creating a perfectly customised layout.

Alternative, manual operating mode

The system can be switched to a manual operating mode to process rush jobs in between. The large automatic front door is then used to load and remove the workpieces to be labelled

The NC-controlled Z-axis is used to adapt to different workpiece heights. This makes it possible to label other plate sizes without a magazine

| Dimensions | 3400 x 1510 x 1950 mm (LxWxH) |

| Max. Number of magazines | 20 |

| Filling height of the magazines | 250 mm |

| Sorting boxes | 50 |

| Weight of the system | 890 kg |

- Robot sorting

- Linear conveyor

- Ring conveyor for 50 sorting boxes

- Ring conveyor for 25 sorting boxes

- DMC camera

- Vision systems

Software

- Pensoft Editor

- Pensoft Connect - ERP connection

- Penteq nameplate software

- Penteq App Development

Accessories

- DMC Camera - VisionSystem Verifier

- Pilot laser

- Laser fume extraction

- Foot switch

- Hand scanner for codes

- touch screen

- 3-stage status light

- Fiberline F20

- Fiberline F30

- Fiberline F50

- UV-Line for plastic cards

Downloads

Matching products

PenSoft Control

Easy-to-use interface for laser applications

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling