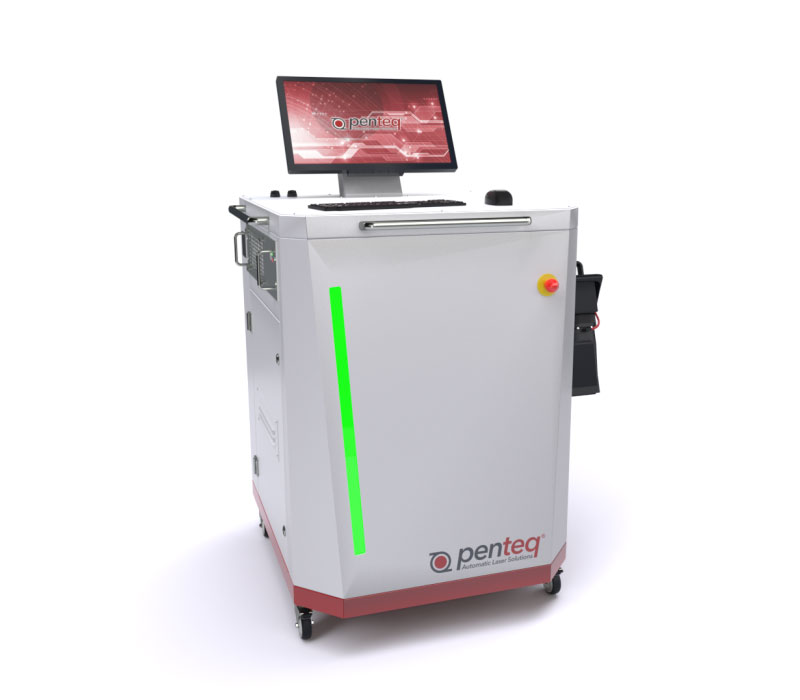

BellCape mobile laser

Mobility meets precision for mobile laser labelling

Flexibility for industrial applications

The MobiLaserMarker BellCape brings the laser directly to your components, which enables enormous time and cost savings, especially with large-area workpieces.

Thanks to the fully integrated laser fume extraction system, which is mandatory for reasons of worker protection, the system fulfils the highest safety standards and is ideal for industrial applications.

Call to Action

Benefit from the advantages of the MobiLaserMarker BellCape

Optimise your production processes with the innovative BellCape system. Contact us today to find out more about the mobile possibilities of this unique laser system.

Full mobility on level floors

With its compact design and castor feet, the BellCape Laser can be easily rolled to different locations on level floors. Ideal for changing production locations or flexible use in large production halls.

Contact surface

The well thought-out design of the system provides a generous table surface for holding the screen and supporting the mouse and keyboard. This makes it easy to create or edit labelling layouts directly on the system. No external preparation is necessary.

Status light

An integrated status light indicates the current operating status of the system, ensuring intuitive operation and safety during use.

BellCape attachments

The BellCape attachments, which can be changed without tools, enable precise work on a wide variety of surfaces. Whether complex geometries or sensitive materials - the attachments can be flexibly adapted.

Integrated PC

The system is equipped with a powerful, integrated industrial PC that enables seamless control and easy integration into existing IT structures.

| Dimensions | 800 x 800 x 1250 mm (LxWxH) |

| Simple labelling field | 70 x 70 mm (other sizes on request) |

| Performance | 20, 30 and 50 watts |

| Active medium | Ytterbium |

| Weight of the system | approx. 80 kg |

| Connection | 230V/50Hz and compressed air |

- Fiberline F20

- Fiberline F30

- Fiberline F50

Mobile laser system - Why not make it even more compact?

1. safety and health protection

The integrated extraction system ensures immediate and reliable capture of harmful smoke and particle emissions directly at the source. This provides better protection for the air quality in the workplace without the need for external, potentially error-prone systems. This not only corresponds to the state of the art, but also fulfils stricter requirements with regard to occupational health and safety.

2. process stability and quality

A constant extraction of smoke and particles in the laser system prevents contamination of optics and ensures consistently high processing quality. Integration into the system means that the extraction performance can be optimised for the processing area - something that is often only possible to a limited extent with external or smaller solutions.

3. ease of use and reduction of external peripherals

Integration eliminates the need for additional peripherals (external extraction units), which simplifies the set-up and reduces potential sources of error. The system is "plug-and-play" - ready for operation without the cumbersome combination of several components.

4. space saving in the overall system

Although the device itself appears larger, internal integration often saves more space in the overall setup, as no separate extraction unit needs to be installed next to or underneath it. The noise level can also be better encapsulated and dampened.

5. ease of maintenance and service access

Penteq emphasises a modular and service-friendly design. The integrated extraction system is easily accessible, simple to maintain and enables filters to be replaced quickly - without additional effort or separate decommissioning of external devices.

6. long-term investment security

The robust and sophisticated construction with integrated extraction is designed for long-term industrial use - not for short-term compactness. This makes the system particularly attractive for applications where reliability, low maintenance and consistent processing quality are paramount.

Matching products

PenSoft Control

Easy-to-use interface for laser applications

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines