Laser system with pocket wheel

Automatic laser system with optimised material flow

Productivity at a new level

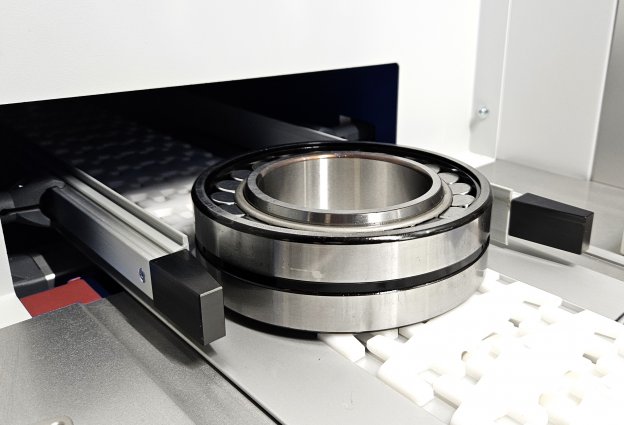

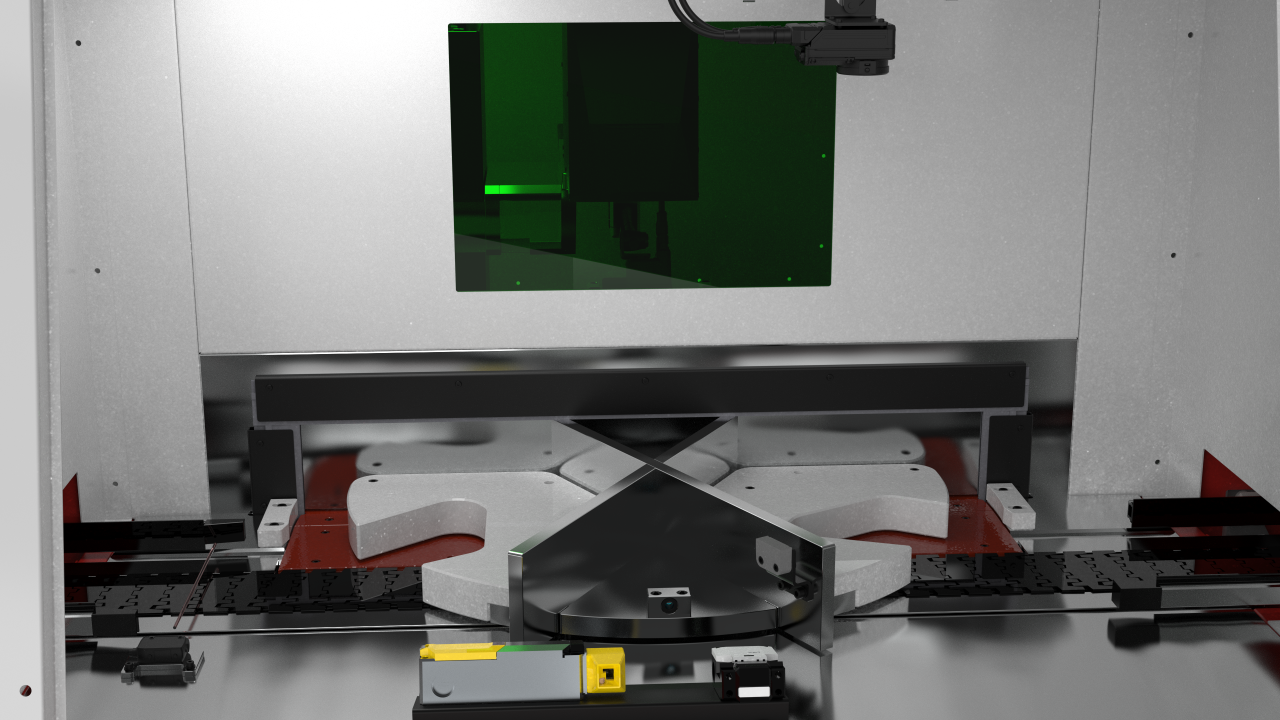

Fully automatic machining of ball or plain bearings as well as all cylindrical workpieces with a favourable diameter to height ratio. The system can be integrated into production lines or operated autonomously by designing a transport section in an O or U shape with return conveyor.

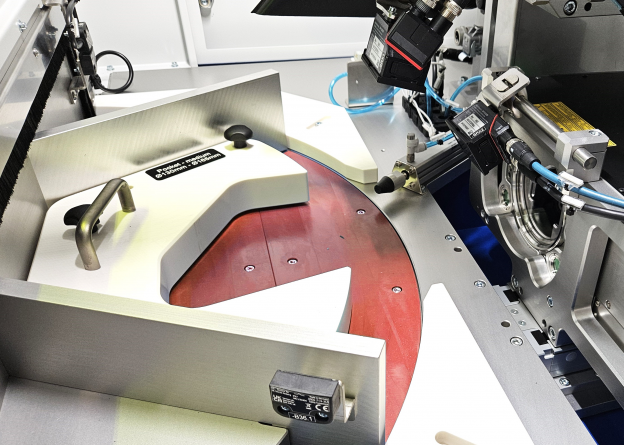

The quick-change pocket wheel inserts are adapted to the products to be processed and cover a defined range of different diameters. The machine frame is designed in a stable welded steel construction and is suitable for many years of industrial use. All components such as the laser supply unit, industrial PC and vision systems are integrated into the system.

Flexible pocket wheel for safe operation

The unique design of the pocket wheel laser system enables non-productive time-optimised operation with maximum safety.

An ingenious geometry reduces manipulation times to an absolute minimum and offers massive time savings in the production of very large quantities

Quick-change pockets

The pockets of the pocket wheel can be changed quickly and easily without tools and cover a defined range of different diameters. The pocket geometries are designed in our in-house fixture construction department and offer our customers a high degree of flexibility and future-proofing.

Simply created - automatically checked

With the "Dynamic Layout Creation" software tool, the input required to create labelling can be kept to a minimum. The lasered codes can be checked immediately after creation so that only 100% legible parts leave production.

Integrated vision systems offer many advantages

Greater efficiency

Automated inspection processes save time and reduce manual effort.

Improved quality assurance

Even the smallest deviations are detected immediately, minimising rework and complaints.

Data analysis and traceability

The systems document and save inspection results, which enables seamless tracking and analysis.

Thanks to the flexibility of modern vision systems, they can be customised to meet specific production requirements. This makes them an indispensable component of laser systems for ball or plain bearing production.

Typical applications:

Colour inspection

Vision systems can detect colour deviations and check whether the colour coding or colour quality of a product meets the requirements.

Checking the presence of recesses

check whether mechanical recesses or cut-outs are correctly attached and in the correct positions.

Code check

The vision systems can apply barcodes, QR codes or other markings to products and ensure that these codes are correct and legible.

Dimensional and geometry inspection

the systems can analyse the dimensions and geometry of a product to detect production errors at an early stage.

Reliability and cost efficiency in one system

Solid construction and precise manufacturing of our laser systems result in a reliable and cost-efficient system. Save costs in the long term and increase your operating efficiency thanks to the durable components and the ability to flexibly adapt to your production requirements.

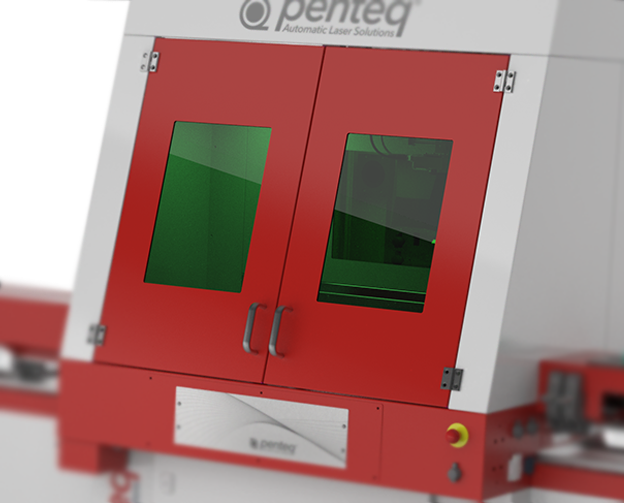

Large front door for optimum accessibility

The double door at the front ensures optimum access to the pocket wheel.

The large, certified laser safety windows provide a safe view and enable visual control of the manipulation process.

Ready for data exchange

The integrated industrial PC and the Windows-based control system offer the best conditions for seamless integration of the laser system with the user's IT system. Connection to ERP systems is easy to realise thanks to standardised interfaces. The Penteq framework enables customised adaptations for a wide variety of processes.

Optimum operability

The screen, keyboard and mouse are mounted on an ergonomically height and tilt-adjustable, solid swivel arm.

It is controlled and operated using PenSoft software specially developed for laser applications, which is easy to use after a brief introduction.

Layouts are created using an intuitive editor, which offers all the usual options for creating a perfectly customised layout.

Challenge us

As a high-tech provider in the field of laser marking, your success and the optimisation of your processes are particularly important to us. Do you have specific requirements? Let us know your needs and we will offer you customised solutions.

Take advantage of the benefits of the pocket wheel laser system and rely on Penteq as your expert for innovative laser systems and laser workstations. Our motto is: "Show us your requirements and we will show you our possibilities!"

| Dimensions (without conveyor) | 2240 x 1900 x 2100 mm (WxDxH) |

| Working range max. | Dia. 400mm (other sizes on request) |

| Simple labelling area | 300 x 300mm (depending on optical configuration) |

| Laser power | 20 - 120 watts |

| Weight of the system | 750 kg (depending on version) |

| Number of pockets | 3 or 4 |

- DMC camera

- Customised bags with quick-release system

- Focus finder

Software

- Pensoft Editor

- Pensoft Connect - ERP connection

- Pensoft Automatic Layout Creation

- Penteq App Development

Accessories

- DMC camera - VisionSystem Verifier

- PSA (Penteq Smart Adjust)

- Pilot laser

- Laser fume extraction

- Foot switch

- Monitor on swivel arm

- Hand scanner for codes

- touch screen

- Bad parts box with switch

- 3-stage status light

- Fibreline F20 - F120

Matching products

PenSoft Control

Easy-to-use interface for laser applications

OEM fibreline

Ready-to-install laser for numerous applications

Signolux UKP Pico

Precision & quality for the highest demands

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications

OEM UV Line

High-precision DPSS laser for your production

OEM Carbonline

CO₂ technology for versatile applications

OEM Carbonline 9300 nm

CO₂ technology for the packaging industry

OEM Greenline

Precision laser for sensitive material processing