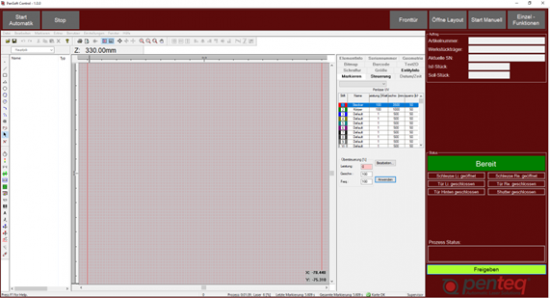

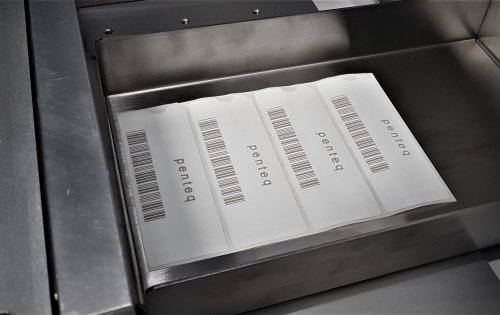

PenSoft Control

Easy-to-use interface for laser applications

PenSoft Control including editor

The software interface is based on the Penteq Framework with integrated editor, which has been developed and tested over many years and is continuously improved and developed further. The entire operation takes place on a software interface from a single mould.

High level of user-friendliness

Multilingual capability

Parameter finder

Integrated parameter database, expandable

Optimised for touchscreen

Different user levels

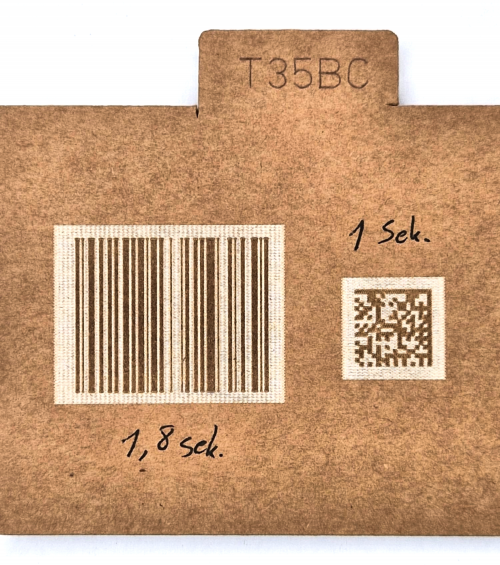

Wide variety of objects (texts, data matrix codes, GS1, QR, serial numbers, graphics, etc.)

Import function for all common formats

Direct control of NC axes such as X, Y, Z, R, swivelling axes, etc.

Vision integration

Layouts are created using an intuitive editor, which offers all the usual options for creating a perfectly customised and designed layout. Here you can drag and drop the individual objects and position them freely in the workspace. Of course, design options such as scaling, grouping and the use of different layer levels are possible. As with all Penteq programs, the software has been developed with very user-friendly features and is also optimised for touchscreen operation. Windows 11 is used as the operating system. Import filters allow existing data to be transferred. Laser parameters can be saved and managed easily and clearly. All common barcodes and ID matrix codes can be displayed. Special PMS add-ons: parameter finder, camera integration, app control, parameter list (material list), ERP connection, maintenance reminder (PenServAssist), special programming can be offered.

Matching products

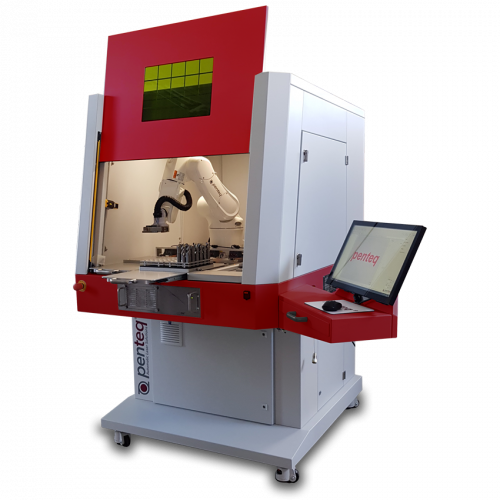

Laser workstation LG 200

Modularity as a pioneering concept

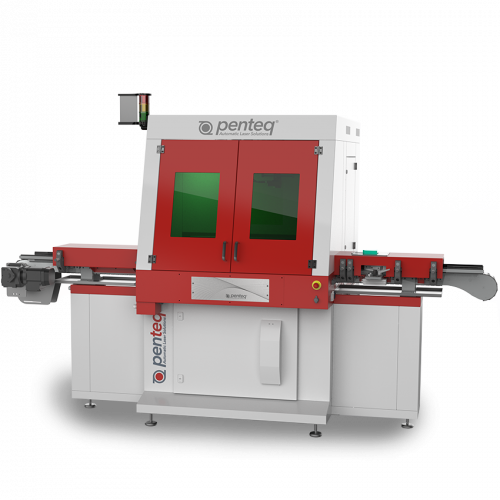

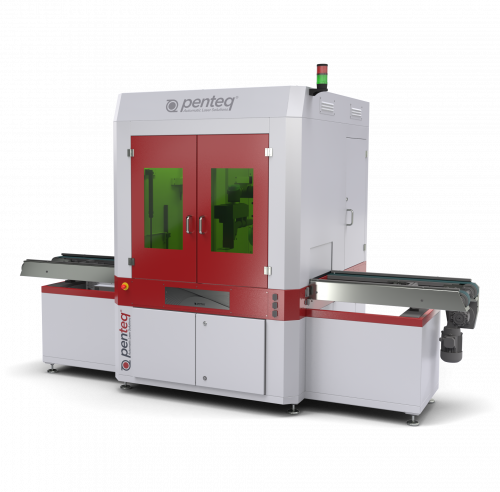

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

BellCape mobile laser

Mobility meets precision for mobile laser labelling

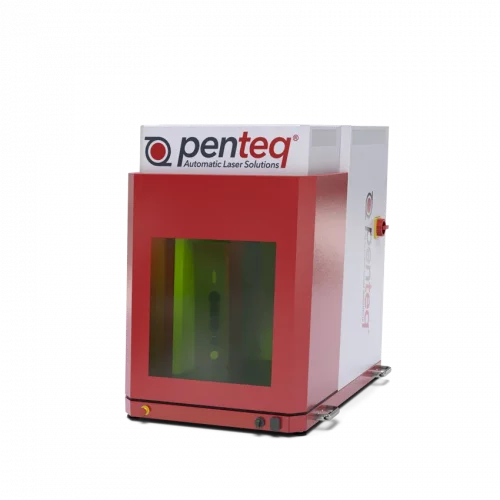

Smartlaser LG20

The intuitive system for professional results

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

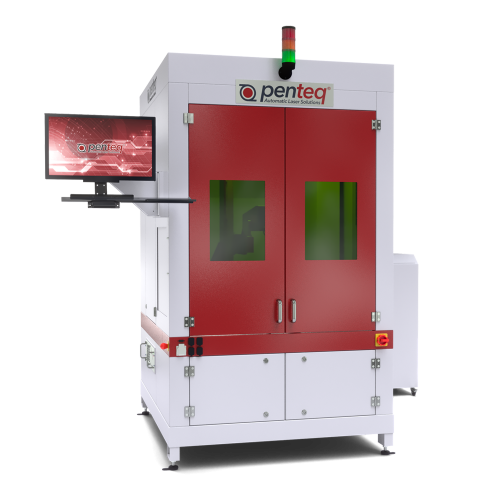

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

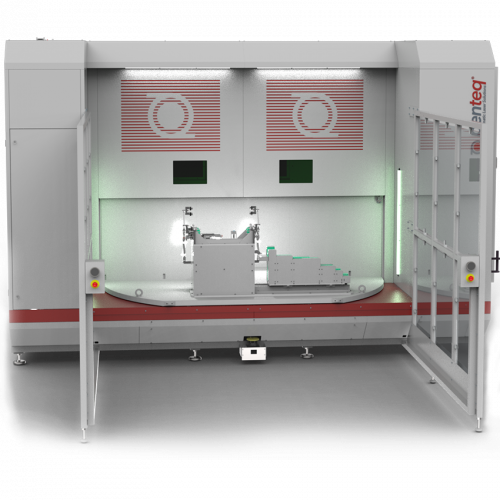

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

Type plate laser machine LG200 PL SB10

for all types of signs

Type plate laser machine LG300 PL SB50

For all types of signs

Type plate laser machine LG200 PL SB50

For all types of signs

Laser system with pocket wheel

Automatic laser system with optimised material flow

LG500 A Double shutter

Automatic loading system for large workpieces

SG 500 RoboLaser

Flexibility through laser robots

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

Turntable Laser system with robot

Turntable system with manipulation and laser robot

Applications

Stripping

Stripping & stripping of copper wires for the electronics industry

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

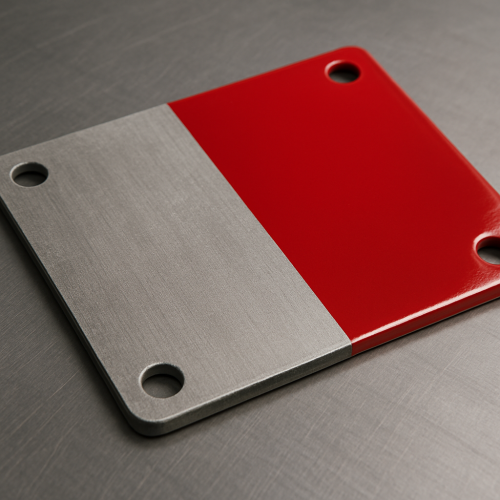

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

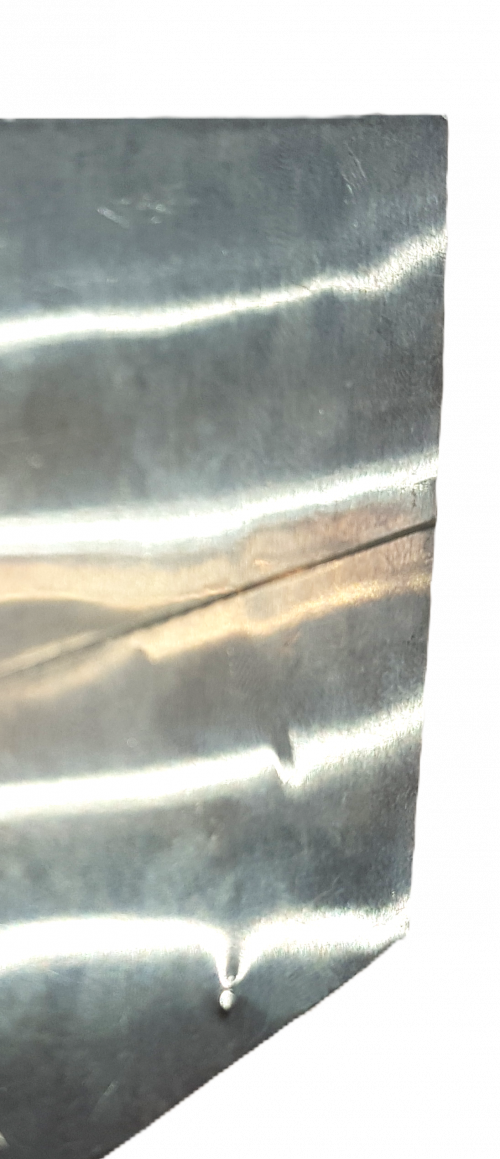

Paint stripping

Removing paint without chemicals or blasting media

Cutting tools

Flexible and durable laser labelling

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

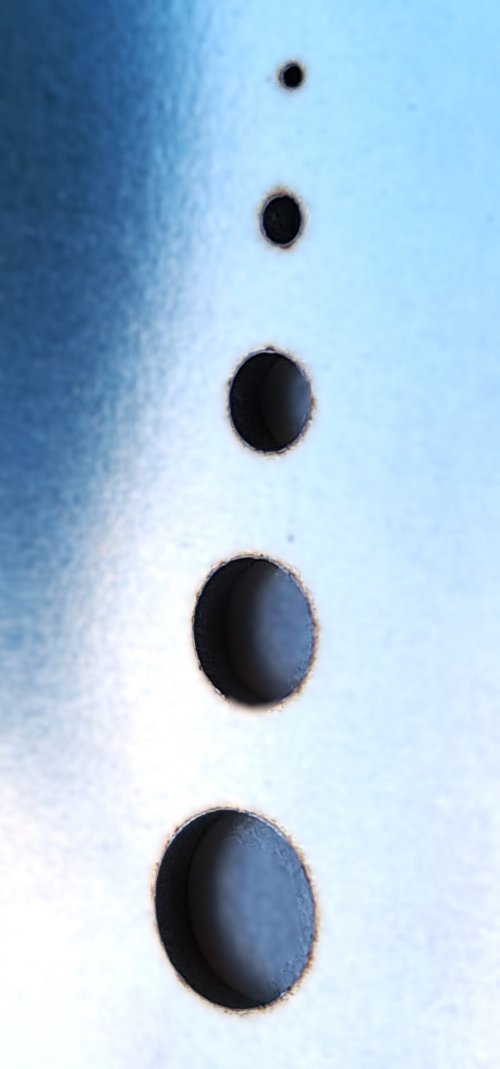

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Watch components

Precisely joining what belongs together

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling