SG 500 Robolaser

Flexibility through laser robots

You can also visit us on our

Maximum flexibility thanks to the laser on robot concept

Many years of experience in the field of laser system production have been incorporated into the development of the machine and software, resulting in an optimised system that offers unprecedented flexibility. The SG 500 RoboLaser is the optimum solution for the automatic processing of workpieces with different angular positions and different surface positions. In addition to labelling applications, it is also particularly suitable for laser cleaning and surface structuring.

Sophisticated technology enables the laser to be positioned quickly and reliably and ensures trouble-free operation. Tried and tested over many years.

The SG500 Robo laser system is designed for long-term industrial use with a sturdy welded steel base frame and powder-coated sheet steel panelling.

Laser cleaning, laser structuring with high-power robotic laser systems

Whether cleaning or structuring large areas

The use of various function modules gives the user maximum flexibility and is the answer to tomorrow's requirements.

Reliability and cost efficiency in one system

A solid construction for many years of use in industrial applications make the SG 500 Robolaser a reliable system.

Save costs in the long term and increase your operating efficiency thanks to the durable components and the ability to flexibly adapt to your production requirements.

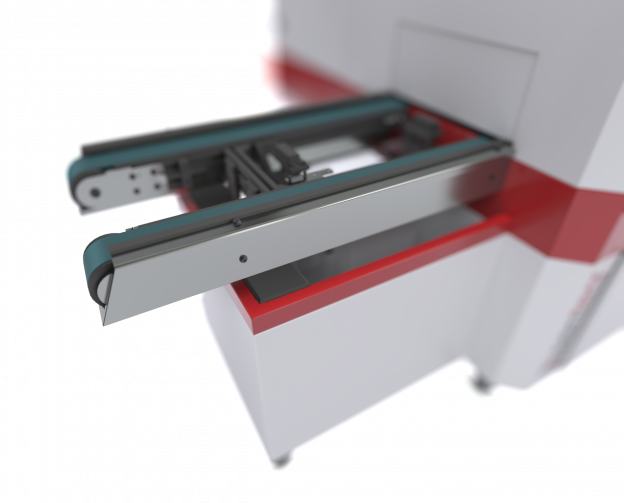

A powered conveyor belt is integrated for the automatic feed and removal of customisable workpiece carriers. Laser class 1 is guaranteed by a special lock system.

No special robot programming knowledge required

Our expertise and customer proximity enable us to develop practical solutions for various applications. The robots integrated in our laser systems can be easily adapted without the need for specialised robotics knowledge.

If the customer defines a product group to be processed, the basic programmes can be offered for automated processing with the system. For a turnkey and carefree installation.

And our many years of experience pay off - our standard portfolio includes a range of handling equipment such as conveyor belts in various designs.

Challenge us

As a high-tech provider in the field of laser material processing, your success and the optimisation of your processes are particularly important to us. Do you have specific requirements? Let us know your needs and we will offer you customised solutions.

Benefit from the advantages of the SG 500 Robolaser and rely on Penteq as your expert for innovative laser systems including software.

Our motto is: "Show us your requirements and we will show you our possibilities!"

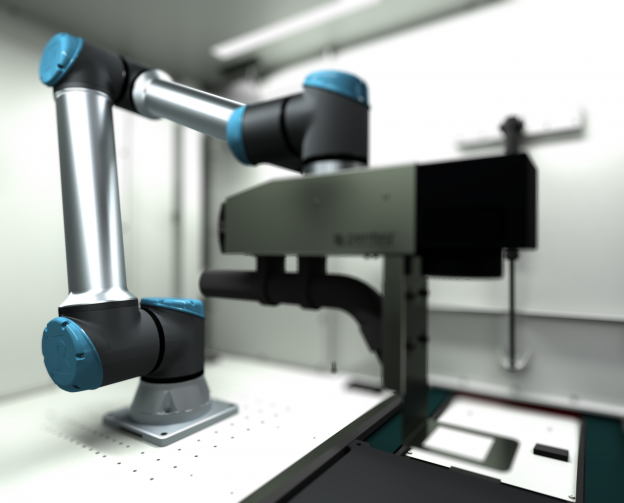

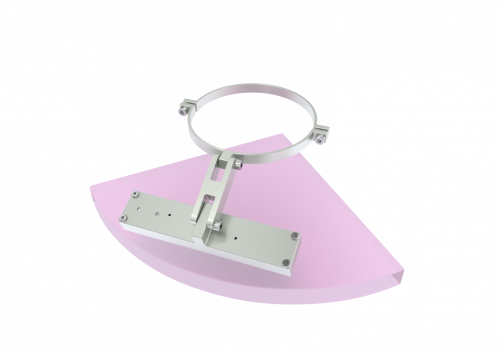

Laser on robots

The laser head, including scanner, is mounted directly on the robot, allowing free positioning in the room.

This makes the system ideal for large-area and multi-sided processing of workpieces.

Automatic workpiece manipulation

The workpieces are automatically fed and removed using customised workpiece carriers via a driven conveyor belt. The workpiece carriers are indexed at the processing position in order to realise high repeat accuracy. Laser class 1 is guaranteed by a special lock system.

Compact design

The SG500 RoboLaser is designed for long-term industrial use with a sturdy welded steel base frame and powder-coated sheet steel panelling.

For alternative loading in manual mode, the door design offers a large opening for convenient loading and unloading, even when handling bulky workpieces. Process monitoring is made possible by a camera installed in the work area.

Adjustable machine feet

The system is equipped with adjustable machine feet as standard to optimise the adjustment of the conveyor height.

This enables a seamless connection to an existing conveyor system.

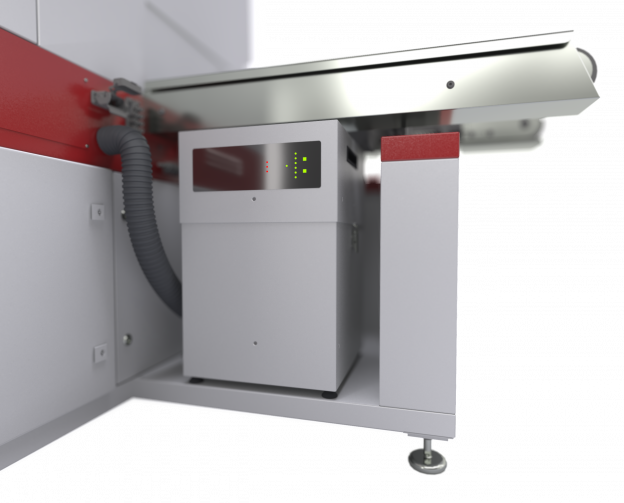

Integrated, special laser smoke extraction system

A fully integrated laser fume extraction system is also included in the scope of delivery. This 3-stage extraction system ensures reliable removal and filtering of the aerosols generated by the laser process. An optional version with self-cleaning filters is available for high removal volumes during laser cleaning processes.

Optimum accessibility to the work area

The double door at the front is dimensioned for optimum accessibility.

The door design offers a large opening for convenient loading and unloading, even when handling bulky workpieces. Process monitoring is made possible by a camera installed in the work area.

Windows Industrial PC

An extremely modern control concept based on an industrial PC and the Windows 11 operating system. Industrial PCs offer more performance and flexibility compared to the classic PLC, especially for complex or networked systems.

Easy access to all functionalities through remote maintenance.

| Dimensions | 4000 x 2000 x 2100 mm (WxDxH) |

| Max. Workpiece dimension | 1000 x 800 x 400 mm (LxWxH) |

| Max. Weight of the workpiece per carrier | 150kg |

| Robots | 6-axis |

| Weight of the system | 980 kg |

- Linear conveyor

- Ring conveyor

- DMC Camera

- Vision systems

- Process monitoring

Software

- PenSoft Control

- PenSoft Connect

- Penteq App Development

Accessories

- DMC Camera - VisionSystem Verifier

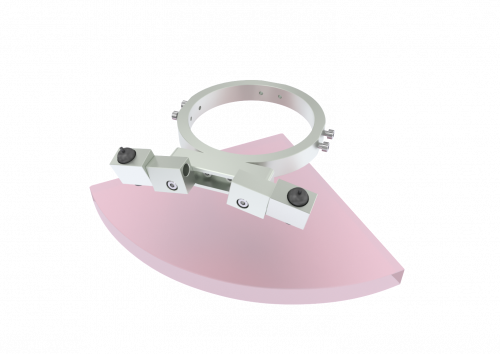

- PSA Smart Adjust

- Laser smoke extraction

- Foot switch

- Monitor on swivel arm

- Hand scanner for codes

- touch screen

- Bad parts box

- LED status light (levels as required)

- Fibreline F20-F5000

- Carbonline

- UV-Line

- UKP Signolux Pico+Femto

- Greenline

Downloads

Matching products

PenSoft Control

Easy-to-use interface for laser applications

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM UV Line

High-precision DPSS laser for your production

OEM fibreline high power

Ready-to-install laser for numerous applications

Applications

Stripping

Stripping & stripping of copper wires for the electronics industry

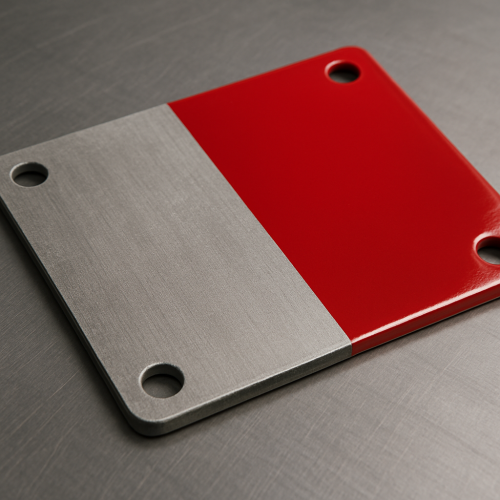

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

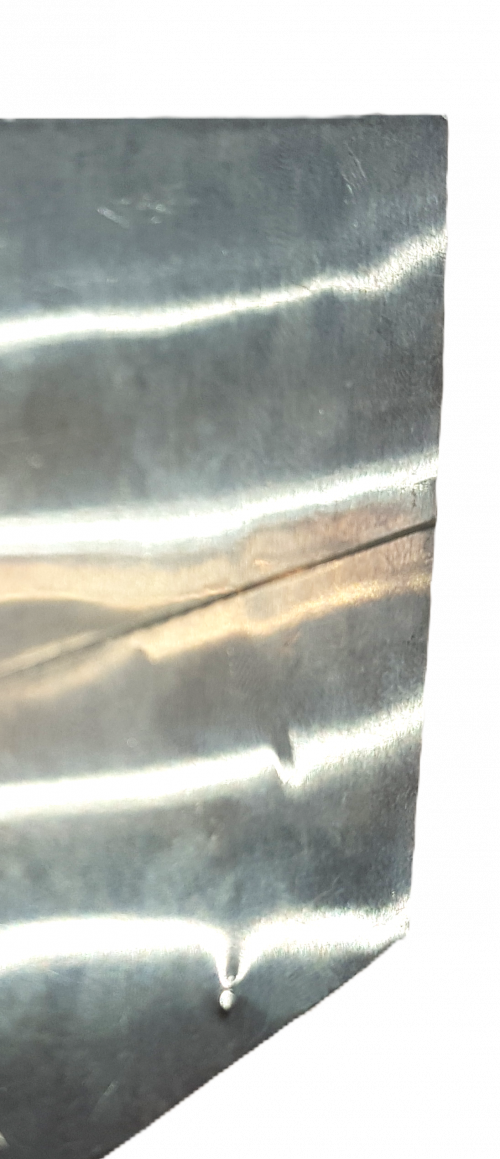

Paint stripping

Removing paint without chemicals or blasting media

Rust removal

Efficient laser cleaning of corroded surfaces

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

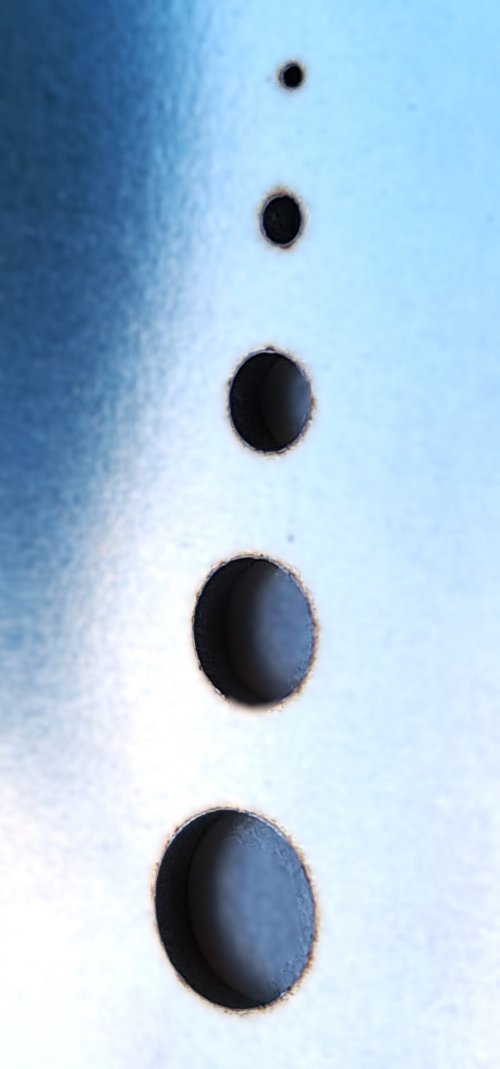

Perforating and punching

Precision laser perforation for demanding materials.

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling