DPW laser welding

Laser welding of metals

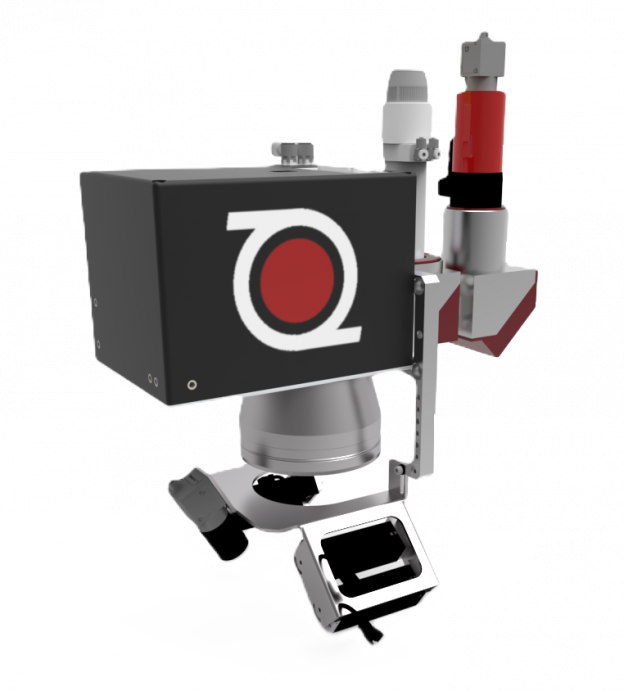

Dynamic Precision Welding - dynamic scanner welding with integrated vision system

Laser welding with the DPW process is the ideal solution for joining metals with high welding speed and low heat input, a small heat-affected zone and minimal distortion. Faster, more precise and more economical than conventional laser welding processes thanks to beam guidance via movable mirrors.

Scanner laser welding DPW

Welding can be performed dynamically in the processing area, thus eliminating non-productive times. Thanks to the design with a scan head, almost non-productive time-free processing is achieved at various process points within the processing field. Numerous advantages in addition to the high flexibility speak in favour of using this modern concept. Any welding pattern can be applied to the components to be welded without additional movement of the workpiece or the welding head. The combination of the laser with a high-performance deflection unit and special software is the ideal combination for achieving optimum welding results.

Laser scanner welding with an integrated vision system and weld seam detection opens up new possibilities in automated joining technology. Especially when processing different materials such as copper, aluminium, steel or material combinations, precise positioning, real-time correction and adaptive process control are crucial for the quality of the weld seam. Our system combines the advantages of scanner optics (high speed, flexible seam tracking) with an intelligent image processing unit that detects the actual position of the components before each welding process and precisely determines the seam position. This enables automatic seam tracking even with component tolerances, distortion or complex geometries - without any mechanical readjustment. In addition, different materials can be welded selectively and reliably, as the system uses laser parameters adapted to the type of material - for example, for welding thin copper with aluminium without risking the formation of cracks or pores.

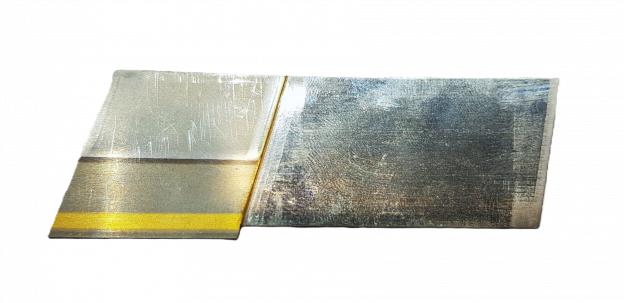

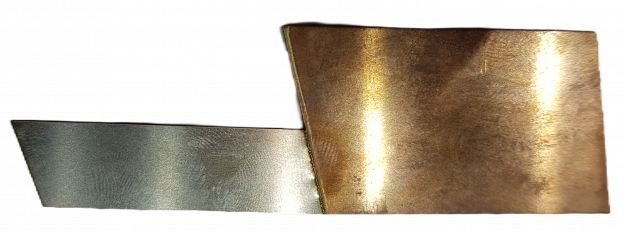

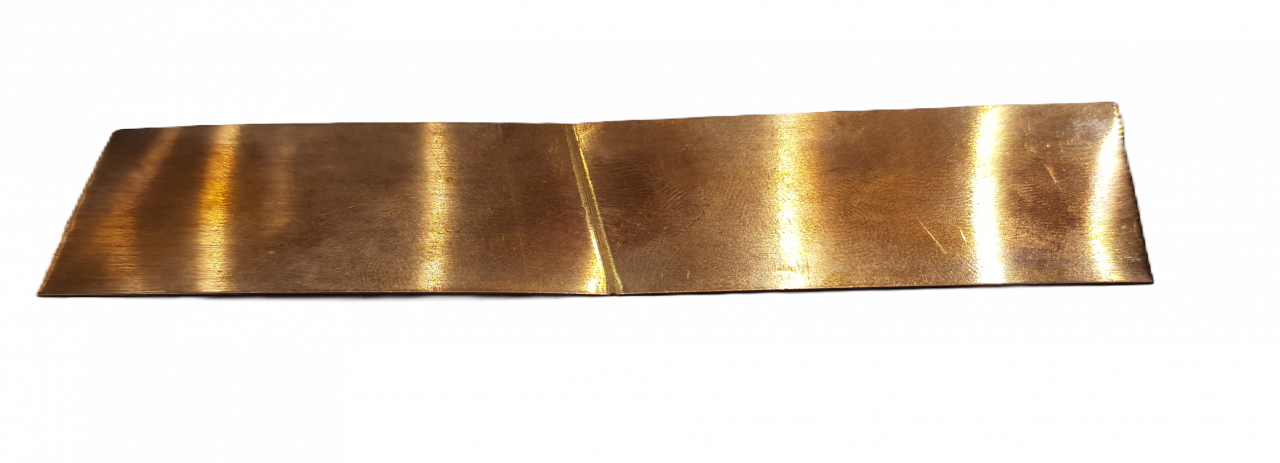

DPW laser welding of strips

The laser welding of precision strips places high demands on accuracy, process stability and cycle time. With our DPW system approach - consisting of integrated image processing and dynamic scanner welding - we realise high-precision welded joints with the greatest possible automation and flexibility.

Our solution combines a high-resolution vision system for component position and edge tracking with a dynamic laser scanner head that adapts the weld seam guide to the recognised geometry in real time. This automatically compensates for even the smallest deviations in the strip position or alignment - without any manual readjustment.

Laser spot welding

A process in which a laser is used to create a single welding spot to join metals. By focussing the laser beam, the light is absorbed by the workpiece and the metal begins to melt. The liquefied metal then solidifies, creating a spot weld. This process takes place in just a few milliseconds. Depending on the material thickness and the desired joint strength, further spot welds are created.

Heat conduction welding

The start of the process is similar to spot welding. This welding process differs from spot welding in that the laser beam can be moved after the molten metal has been produced. The welding depth is usually less than 2 mm, which is why this joining process is mainly used for thin metals.

Advantages

Flexible and economical

- Minimal thermal deformation - ideal for thin and sensitive materials

- High process speed thanks to scanner technology

Fast laser movement via galvanometer mirror - ideal for fig-shaped seams, structured seam patterns and punctual connections

Monitored

- Inline quality control & data recording

Seam analysis, process monitoring and connection to MES or QA systems

Process reliability

- Real-time compensation & adaptation: Seam path and welding strategy are automatically adapted to varying belt geometries.

- Automated, reproducible joining process without reworking. Ideal for series production with changing component geometries with simultaneous control of the process

Precise

- Vision system for precise component detection

Automatic detection of belt edges, joining positions and tolerance deviations in real time

Application examples:

Welding of thin strip materials in sensor and microsystem construction

Joining metal foils in medical technology

High-precision transverse weld seams with tape feed

Joining the smallest components in mechanical watches

Welding batteries with busbars

Suitable products

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods