Laser labelling of electronic housings

Precise. Durable. Traceable.

Laser labelling of electronic housings

Individual, precise and permanently legible laser marking for the highest demands in the electronics industry.

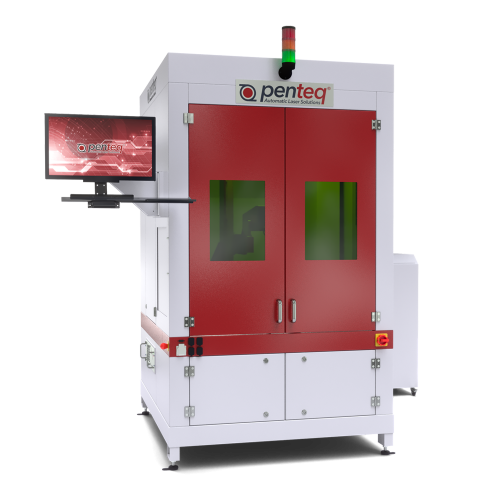

Penteq offers the widest range of laser systems for electronic housings on the market, from one-off production to mass production.

Variety & precision - Professional laser labelling for electronic components and housings

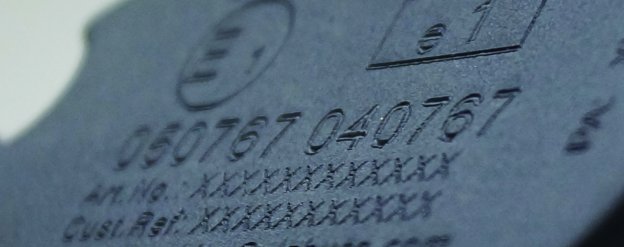

In modern electronics production, the professional labelling of housings plays a central role - be it for the traceability of components, for marking serial numbers or for displaying the brand logo. Laser labelling has established itself as a particularly efficient and durable method. It makes it possible to apply permanent, abrasion-resistant and high-contrast information directly onto the housing - without the use of inks, labels or additives.

With laser systems from Penteq, you benefit from excellent labelling quality on almost any material.

Laser labelling - precise, durable, economical

Penteq's laser systems mark materials completely contact-free, so that even sensitive surfaces remain undamaged. Because the laser does not physically touch the workpiece, there is no risk of scratches or damage.

Whether plastic, anodised aluminium or stainless steel - with the right laser system, a wide variety of materials can be marked with high precision without endangering the sensitive electronics inside. Even the smallest font sizes, QR codes or DataMatrix codes can be applied without contact and later read by machine. This makes laser marking not only the ideal solution for marking individual devices, but also for automated production lines and Industry 4.0 processes.We offer you customised laser marking solutions for electronic housings - from prototypes to series production. With state-of-the-art technology, high quality standards and fast implementation, we ensure that your products are labelled in accordance with standards, securely and unmistakably.

Unique & versatile - customised laser markings according to your requirements

Penteq's laser systems offer a wide range of customisation options, allowing you to apply individual markings exactly as you want them. The laser beam can be used to create not only different colours and shades, but also highly visible or discreet and concealed markings.

Laser labelling is a versatile, reliable technology that allows you to mark nameplates permanently, precisely and gently. Use it for labelling simple systems for small quantities or choose semi-automatic and fully automatic systems for the production of large and very large quantities. Our solutions can be flexibly adapted to any requirement. You always benefit from high labelling quality, a wide range of design options and reliable, efficient production - from individual items to industrial mass production.

Your benefits from laser marking at a glance

Versatile applications

- Suitable for almost all materials, e.g. plastic, aluminium, stainless steel

- Various processes can be used, such as engraving, annealing marking or colour layer removal

Maximum flexibility

- No minimum quantities per design variant

- Customised production directly in the production line ("just-in-time")

- Simple customisation of content (serial numbers, codes, logos)

Forgery-proof and traceable

- Permanently readable DataMatrix QR and barcodes

- Protection against tampering thanks to tamper-proof labelling

High-quality labelling

- High resistance to heat, chemicals and abrasion

- Quality testing in the plant

Efficient and economical

- No mechanical stress, the sensitive electronics remain protected

- No surplus due to demand-orientated production

- Reduced procurement and administration costs

- No minimum quantities required

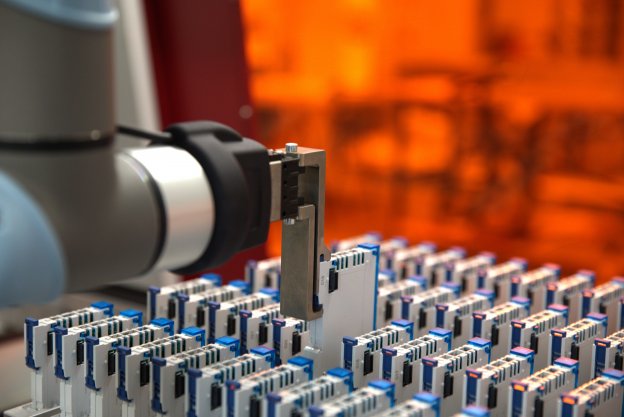

Robots and vision systems

Integrated manipulation robots and vision systems enable continuous inspection at various positions on the product.

QR or Data Matrix codes can be checked in accordance with the AIM-DPM standard and the results saved with a time stamp for traceability. In addition, the inspection of product properties such as colour, presence of drill holes and connectors can be integrated into the process.

Suitable products

Integration station

Laser system for easy integration into conveyors

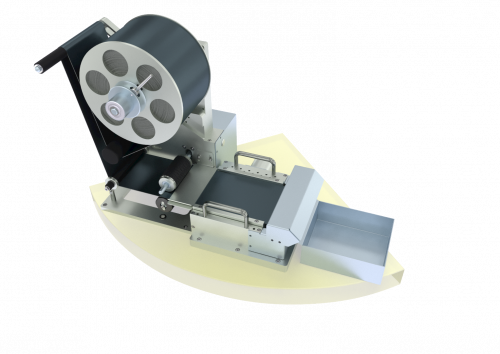

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

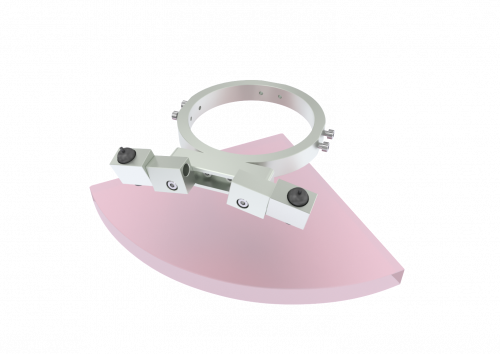

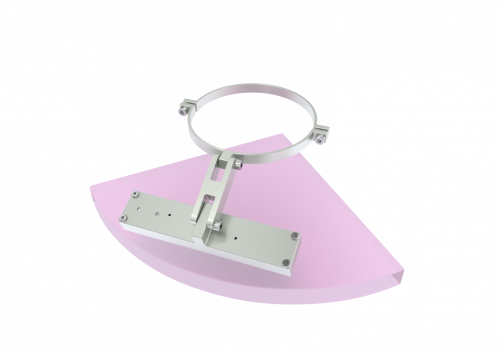

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines