Glass + ceramics

High-precision, material-friendly engraving + labelling

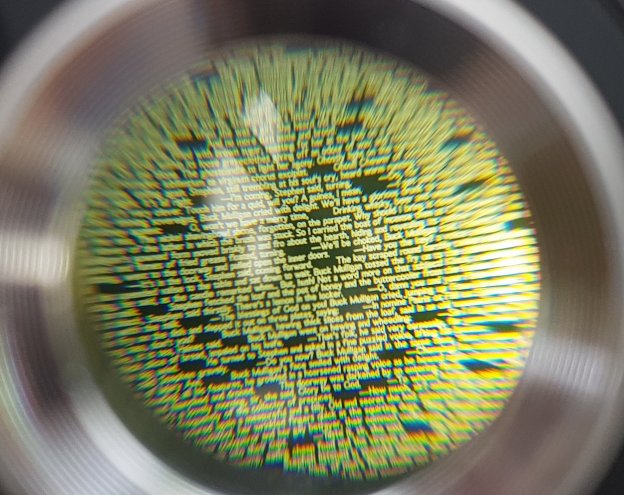

Laser labelling & engraving of glass and ceramics

Precise. Durable. Contactless.

The laser marking and engraving of ceramics requires particular precision and experience, as these materials are among the hardest and most brittle materials. The right choice and suitable optical configuration of the laser system in combination with the process parameters specially determined for the respective application during application development guarantee optimum results, permanently.

Variety & quality

Glass and ceramics are among the most precious, but also the most sensitive materials in technology, design and industry. Our specialised laser marking processes enable high-precision, material-friendly engraving on almost all types of glass and ceramics - optionally also with Signolux ultra-short pulse laser technology (USP) for the highest demands.

We offer turnkey solutions for the production of large and very large quantities with automated systems.

Damage-free glass labelling

The laser marking of glass places high demands on precision and material protection. Due to its transparency and brittleness, conventional laser processes can easily lead to stress cracks, unwanted clouding or chipping. To avoid this, we rely on two highly specialised technologies. UV lasers and ultra-short pulse lasers (USP). The UV laser works with a wavelength of 355 nm and enables particularly fine, high-contrast markings on glass - for logos, codes or technical labelling, for example. Thanks to the high absorption in the ultraviolet range, glass can be modified locally without heat penetrating into deeper layers. This results in precise, smooth and permanent markings, ideal for applications in electronics, medical technology or design objects.

Glass labelling with UKP Signolux

The Signolux UKP laser is used for the highest demands. This technology generates ultra-short laser pulses that ablate the material by "cold ablation" - without contact, without thermal influences, without micro-fractures.

USP lasers enable micro lettering, filigree engravings and even structured effects on sapphire glass or technical glass - with maximum edge quality and without impairing the strength of the component.

Labelling and engraving ceramics

With modern laser technologies - in particular the Signolux ultra-short pulse laser (USP) and pulsed fibre lasers - permanent, high-resolution markings and engravings can be created on ceramic surfaces without thermally stressing or damaging the material. Depending on the application, the marking can be used for functional or design purposes, for example to refine housings, implants or precision components. The laser produces non-contact, abrasion-resistant markings that can be applied to small areas with high repeat accuracy. Signolux USP lasers deliver excellent results, particularly with glazed or high-density ceramic materials such as aluminium oxide (Al₂O₃), zirconium oxide (ZrO₂) or silicon nitride. They enable micro-engraving with high edge quality, without cracks or material flaking - a decisive advantage over mechanical processes.

The advantages of laser marking on glass and ceramics

Flexible and economical

- Labelling with logos, plain text, serial numbers and codes

- Individualisation

- No consumables such as labels or inks

Forgery-proof

- Tampering leaves visible traces

- Traceability of products through Data Matrix codes

Precise

- Outstanding labelling quality

- High contrast and high read reliability

- Fast

Resistant

- Highly resistant to heat, abrasion and chemicals

- Functional engravings with defined depth

Suitable products

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines