Technical films

Precise, fast and clean cuts

Laser cutting of foils with galvo systems

Precision, speed and flexibility for the highest demands

The advantages of scanner laser cutting at a glance

Flexible and economical

- Ideal for changing contours, small batches or customisation - without changing tools.

- Efficient: "Just-in-time production" as required No minimum quantities per contour variant

No surplus production (waste of material)

Low procurement and administration costs

Non-contact and wear-free

- No tool contact, no deformation due to the application of force

- No tool costs

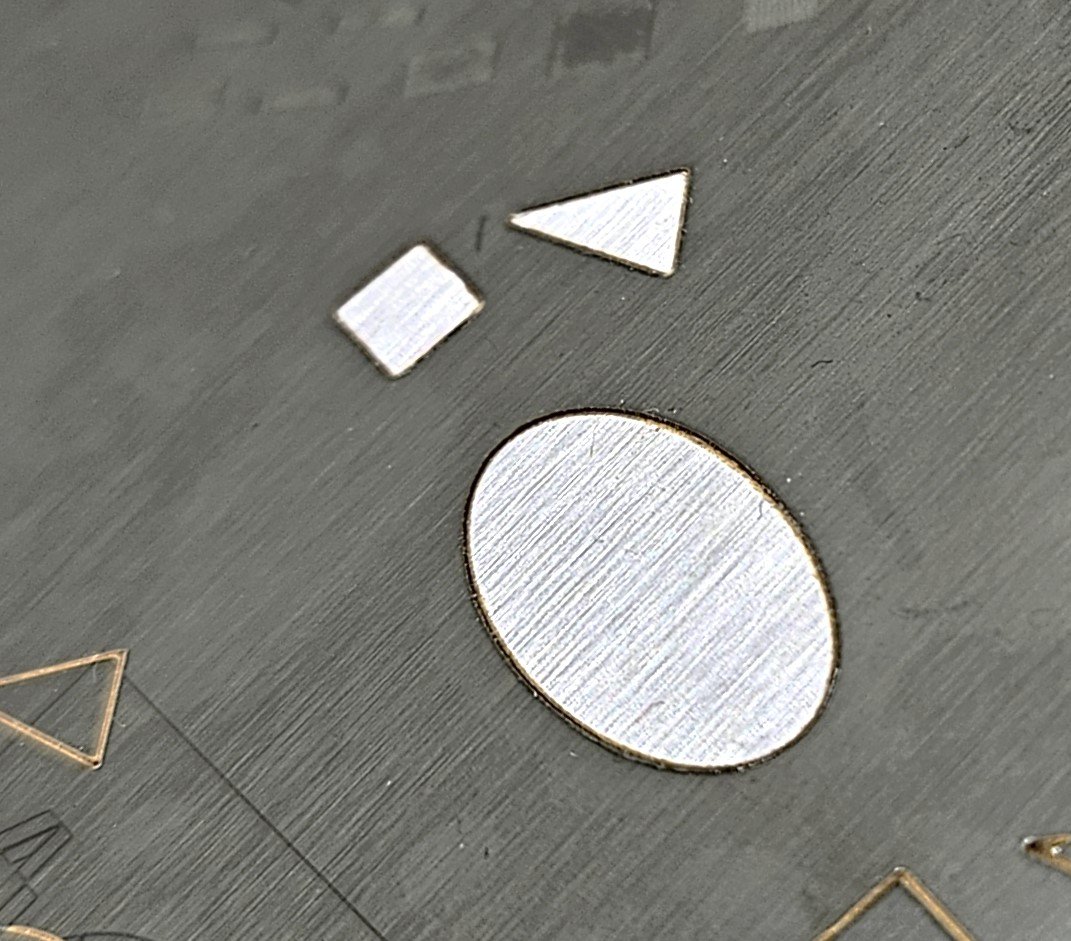

Precise

- Outstanding cutting quality

- Clean cut edges and minimal burr formation

- Low thermal load

Highest processing speed

- Thanks to dynamic beam guidance through the galvo mirrors - ideal for large quantities and short cycle times.

- Cut sensitive materials without breaking or burning.

Laser cutting of films using the roll-to-roll process

The precise and economical processing of films plays a key role in industrial production - especially in high-tech sectors such as electronics, medical technology and automotive. One of the most innovative technologies in this area is laser cutting using the roll-to-roll process, in which the material - thin plastic, metal or composite films - is continuously unwound from a roll, processed and then wound up again. Laser cutting enables contact-free, high-precision cuts, even with the finest structures or sensitive materials. Advantages of laser cutting using the R2R processHighest precision: Micro cuts down to the sub-millimetre range are possible without any problems - ideal for electronic components, sensors or medical components.

Non-contact & wear-free: No tool contact means less mechanical stress and no tool wear.

Flexibility in contour design: Geometries can be adapted quickly and without mechanical changes.

High process speed: The continuous material feed enables fast cycle times - even for complex patterns.

Clean cut edges: No fraying or smouldering as with mechanical processes.

Variety of materials: From PET and polyimide to metallised films - almost any type of material is suitable.

Some typical applications:

Flexible printed circuit boards and circuits

Carrier films for microcomponents

Masks and cover films in medical technology

Touch sensors and displays

Sealing films for automotive applications

Suitable products

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines