Laser drilling

Create a large number of precise holes

Laser drilling of precise holes in sensitive materials

A wide variety of materials such as steel, ceramics or multi-layered materials can be drilled using lasers. The process is also particularly suitable for sensitive and brittle materials.

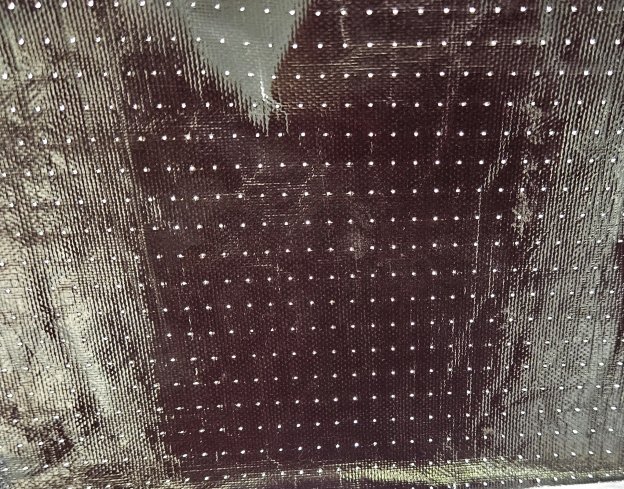

Precise laser drilling of thin materials

Laser drilling of fabric enables the precise, contactless creation of extremely fine micro-holes in textile or non-woven materials. This method is a precise alternative to mechanical processes, particularly in sensitive areas such as medical technology (e.g. wound dressings, implants), filter technology and functional clothing. Thanks to galvo systems, drilling patterns can be realised with high speed, repeat accuracy and minimal thermal influence - ideal for sensitive, flexible materials. Synthetic fabrics such as polyester, polyamide or polypropylene as well as technical textiles and selected natural fibres are suitable. The process impresses with a high degree of design freedom, burr-free results and excellent material protection.

Signolux ultrashort pulse laser (UKP) for ultra-fine drill holes

Laser drilling with ultrashort pulse lasers (Signolux picosecond or femtosecond lasers) enables absolutely precise, virtually burr-free processing of the most sensitive materials - even for micro holes in the single-digit micrometre range. Due to the extremely short pulse durations in the range of trillionths or quadrillionths of a second, material ablation is carried out "cold", i.e. without any significant heat development. As a result, the surrounding material is hardly affected - a decisive advantage for thermally sensitive materials or when the highest structural quality is required.

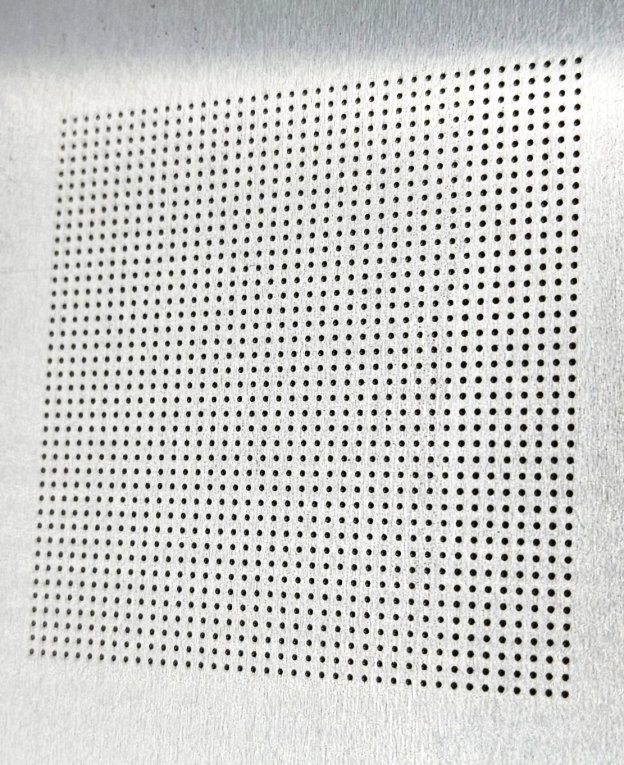

Production of high-precision sieves

Microstructured screens for the highest requirements. Our laser technology enables the production of the finest screens and filter structures with the highest precision and repeat accuracy. Thanks to galvo systems, thousands of micro-holes with precisely defined diameters and pitches can be realised in a very short time. Perfect for applications where mechanically punched or etched screens reach their limits.

Galvanometer scanner for flexible drilling patterns

Galvo systems enable fast and precise deflection of the laser beam over a large processing field. The laser beam is positioned via movable mirrors, vibration-free and with high dynamics. This makes it possible to create precise drilling patterns, as no mechanical movement of the workpiece is required in the working area. The working range of the system depends on the laser used and the optical configuration. Thanks to the programmability, the bore diameters and distances can be flexibly customised - from bore to bore.

The advantages of laser drilling with galvo systems

Flexible and economical

- Flexible design: Both the bore diameter and the spacing (pitch) of the bores can be freely defined.

- Customised "just-in-time production" of special screens

- Customised diameters and spacing per individual product possible without set-up effort

Process reliability

- Ideal for automated series production

- High process stability with consistent materials

Precise

- Outstanding drilling accuracy

- High repeat accuracy

Fast

- High processing speeds due to fast beam deflection

- Minimal thermal influence

Laser drilling using the roll-to-roll process (Roll to Roll-R2R)

Laser drilling using the roll-to-roll process (R2R) enables continuous, high-precision processing of flexible web materials - ideal for applications with high quantities and tight tolerances. In combination with fast galvo systems, micro holes with high repeat accuracy and freely selectable geometry can be produced inline and with continuous material feed. This allows perforations, screen structures or functional hole patterns to be realised efficiently and economically - without mechanical wear or set-up times.typical materials in the R2R laser drilling process are polymer films (e.g. PET, PI, PE), metal foils (e.g. copper, stainless steel) or laminated and coated substrates. The process is used in areas such as electronics production, filter technology, medical technology, battery production and the packaging industry, etc. The major advantage: thanks to the combination of precise beam guidance, continuous material movement and process monitoring, R2R laser drilling offers maximum productivity with consistent quality - even with complex patterns and the finest hole diameters in the micrometre range.

How many holes do you produce?

Laser drilling using an electroforming system is ideal for a wide range of demanding applications where maximum precision, minimum thermal stress and fast processing are required. Typical areas of application include electronics production, where the finest micro-drilling is required in printed circuit boards, flexible substrates or foils for sensors and microelectronics. The process is also used in medical technology, for example to produce micro sieves, filter foils or nozzle plates for spray and nebuliser systems. In microfluidics, the technology enables the precise perforation of plastic or glass structures, for example for lab-on-a-chip systems. Other applications include the perforation of technical films for the packaging and food industries as well as the selective drilling of functional surfaces in automotive or energy technology. Suitable materials for laser drilling with galvanometer scanners include thin metal foils such as stainless steel, copper or aluminium, but also technical plastics such as polyimide (PI), polyethylene terephthalate (PET) or polymethyl methacrylate (PMMA). In addition, brittle materials such as thin glass, ceramics or semiconductors such as silicon can also be processed with precision. The decisive factor here is the combination of material-adapted laser selection and precise beam guidance by the galvo system, which enables burr-free, sharply contoured drilling even with complex geometries.

Are you planning a project?

We support you from the initial idea through to series production - including design consulting, prototyping and system integration.

Suitable products

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines