Spot welding with Galvolaser

Spot welding with galvo laser systems

Maximum efficiency in laser welding of metals

With our laser galvo systems for spot welding, you can realise precise spot welds in the shortest possible time - contactless, gentle on the material and with maximum repeat accuracy. Ideal for demanding applications in electronics production, medical technology, the automotive industry and precision mechanics.

How does spot welding with Galvo systems work?

In spot welding using galvo scanners, a focussed laser beam is directed onto the workpiece surface via movable mirrors (galvanometers). In contrast to mechanical axis systems, the laser beam is positioned extremely quickly and without moving the workpiece.

Why galvo laser welding instead of conventional?

Compared to conventional CNC or robot welding systems, galvo laser welding enables a significantly higher processing speed, especially when there are many welding points in a small space. At the same time, mechanical inertia is eliminated, making the process ideal for mass production and miniaturisation.

Typical applications:

Micro-welding in electronics production

Battery contact welding (e.g. Li-ion cells)

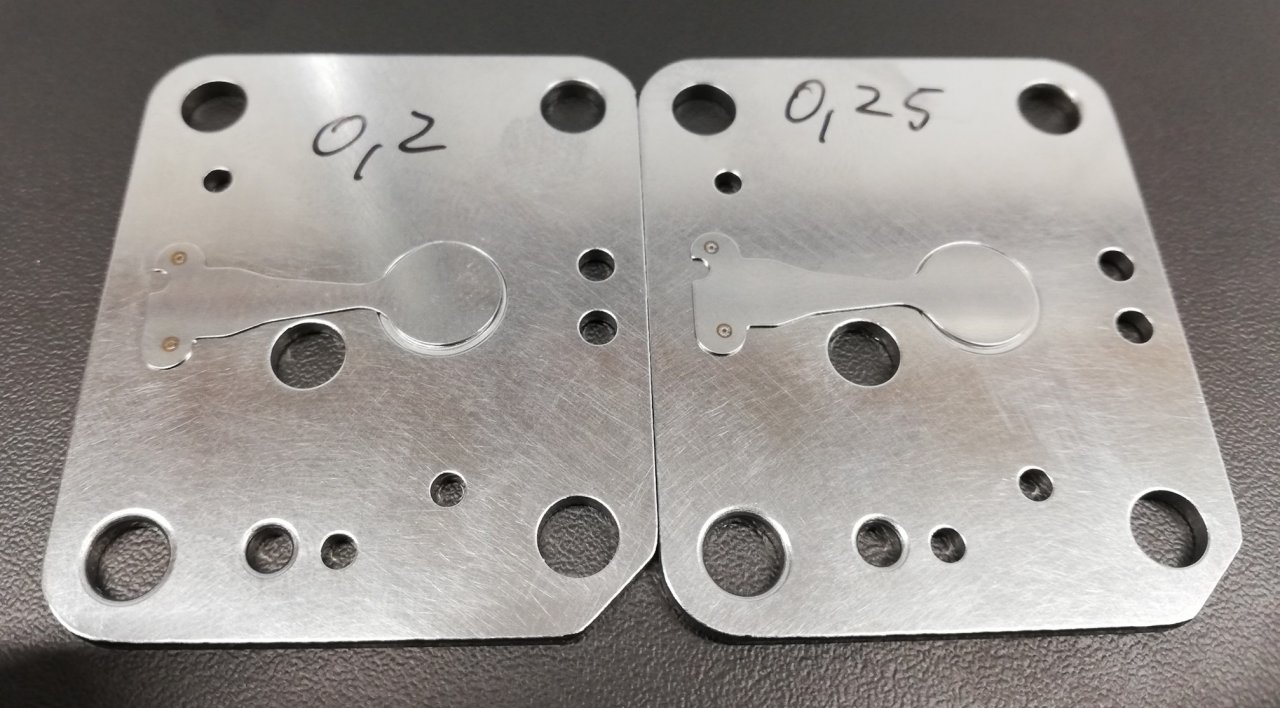

Welding of thin sheets, wires and foils

Medical technology components (e.g. surgical instruments)

Automotive parts in the sensor or control unit sector

Advantages

Flexible and economical

- Highest speed - positioning in milliseconds

- Contact-free process - no mechanical load on the workpiece

Easy to automate

- Ideal for geometries that are difficult to access or complex

- Can be integrated into automated production lines

Precise

- Smallest spot welds with high precision

- Very good reproducibility in series production

Laser spot welding with galvo scanner - high-precision spot welding at maximum process speed

Laser spot welding with galvo scanners is a state-of-the-art method for the precise joining of metallic materials. The laser beam is deflected by two fast-moving mirrors (galvanometers) and focussed precisely on the welding spot. The laser beam is moved without contact and at extremely high speed, making the process particularly efficient and low-wear.

In contrast to conventional laser welding systems with mechanical axis movement, the galvo scanner offers significantly higher dynamics and positioning speed. This is a decisive advantage, particularly in applications with many welding points - for example in electronics production, medical technology, sensor technology or battery cell welding.

The high precision of the Galvo system enables the smallest welding points to be set with exactly reproducible energy input. This means that even thin-walled or temperature-sensitive components can be joined reliably. In combination with pulsed or continuous fibre lasers, the heat-affected zone can be optimally controlled to prevent distortion or material damage. The process can also be easily automated and integrated into existing production lines. Quality assurance functions such as online weld seam monitoring and camera support can also be realised as an option.

Suitable products

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods